RAAC Investigation and Structural Strengthening

Beta Background

Beta Design Consultants were commissioned by the client, University for the Creative Arts (UCA), to provide structural investigation, structural assessment and consulting services regarding the structural integrity of reinforced autoclaved concrete (RAAC) roof panels, their condition, and to report on how to strengthen the RAAC roof in line with the IStructE Guidance and Further Guidance on RAAC.

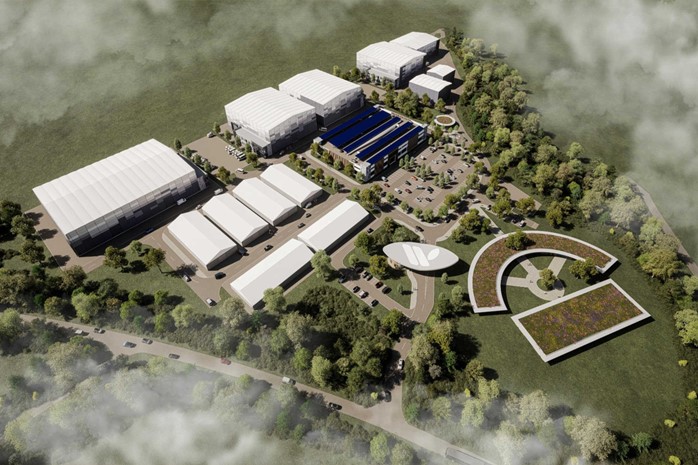

The campus was constructed around the 1960s and some RAAC roof panels were discovered within the Farnham campus during a surveyor inspection, following the BBC news on the collapse of a RAAC panel in a school.

The activities included:

- Visual Inspection of existing roof and confirmation of the presence of reinforced autoclaved concrete (RAAC) panels within the roof.

- Structural Investigation (intrusive and NDT) and Structural Assessment of the RAAC panels capacity for the existing condition and for the proposed condition as the client required to upgrade the roof. The structural investigation included:

- Schmidt Hammer Test to determine the compressive strength of the panels

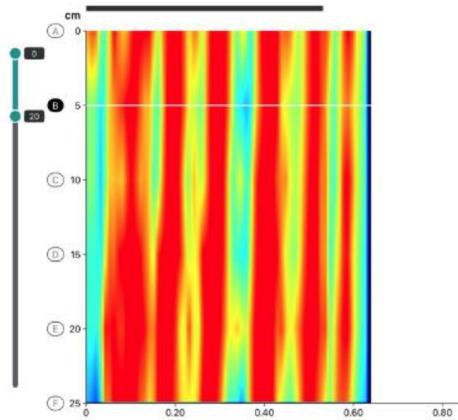

- Ground Penetration Radar survey to confirm the rebar layout.

- Ferro-scanning and intrusive inspection of the panels to determine the rebar layout, depth, diameter and cover, especially the transverse rebars above the supports.

- Core drilling of roof panels for Laboratory testing to determine the compressive strength of RAAC panels.

Beta Solution

We carried out an intrusive inspection, including core drilling of the roof slab and exposing the waterproofing locally, to determine the compressive strength of the concrete and to identify the bearing length of the panels. This enabled us to establish both the bearing length of the roof panels and their compressive strength.

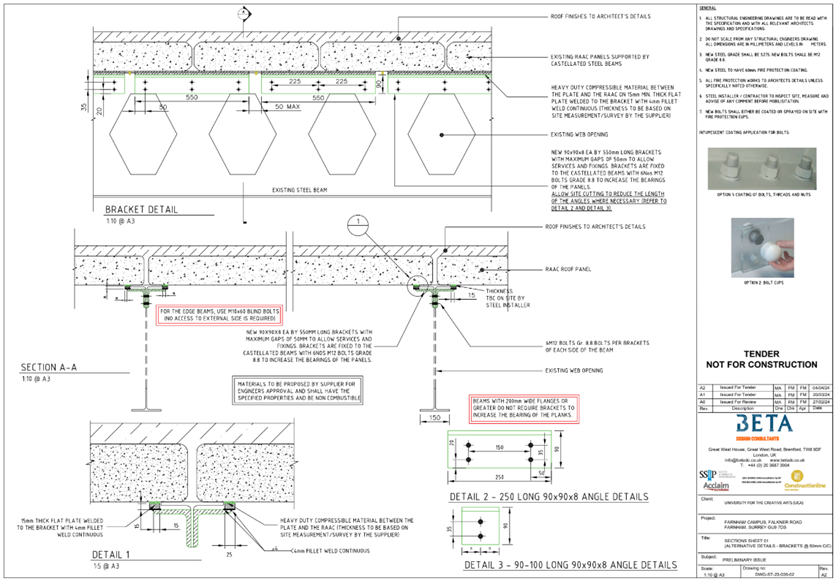

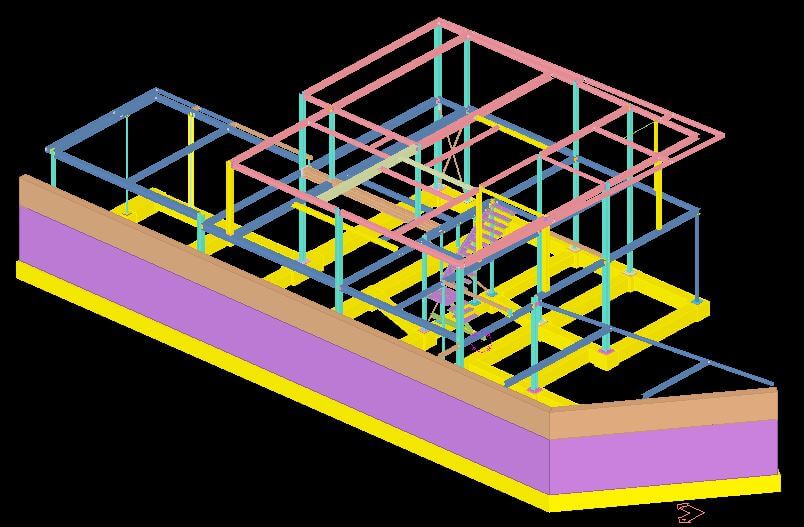

Due to the impact of upgrading the roof insulation (resulting in increased self-weight) and the roof panels having a bearing length of 60-65mm, which is less than the recommended bearing length for the RAAC panels, we recommended increasing the panels' bearings width. We proposed to achieve this by adding steel brackets that we designed to be fixed to the existing supporting steel beams. WE recommended installing these brackets before adding the additional overlay to the roof.

As per the advice of the IStructE RAAC Guidance and Further Guidance, we organized with the client and their maintenance team, Mitie, a presentation on RAAC risks to explain to the client’s management team ways to manage risks of this roof and how it can be managed on site.

One of the challenges was to establish the RAAC panel capacity for bending and shear under the additional loading. The solution was to develop a rigorous analysis that reflects the RAAC characteristics and to carry out assessments for the panels in both their existing condition and the proposed condition. Another challenge was to ensure the solution was buildable considering fire risks, services and need to install solution during the university break.

Client: University for the Creative Arts

Related projects

Kennedy Institute Extension - Flat Slab Punching Shear Strengthening

Read More

Concept Design of Cité Administrative Koloma

Read More

Peckham Arch Condition Survey & Life Extension Consulting Services

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

Action Court Warehouse Extension

Read More

CFRP and HPC Concrete Strengthening for Brindleyplace

Read More

Leisure Swimming Pool House Design

Read More

Engine Yard Punching Shear Slab Strengthening

Read More

CPS House Jacketing to Strengthen RC Beams

Read More

BP Deep Water Sump Assessment and Concrete Repair Design

Read More

Planning Application for Three Story Residential Building

Read More

BP Heater Foundation Concrete Repair

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

BP GF Gas Plant – Slug Catcher Foundation Walls RC Repair

Read More

Fulham Palace Road Temporary Works Design

Read More

Value Engineering for Warehouse and Office Building

Read More

Harwell Campus-Concrete Strengthening

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

Structural Repairs of a Listed Building

Read More

Orchard House – RC Column Strengthening using CFRP

Read More

Structural Design of 3 Storey Building

Read More

Queens Rise- Steel Structure Connection Design and Detailing

Read More

Stanmore House Strengthening

Read More

Bus Depot Electrification Harrow

Read More

Nant Melyn Bridge Inspection for Assessment

Read More

Stage 50 Wycombe Film Studios Village

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More

Stage 50 Bovingdon Airfield Studios

Read More

Coast Drive Visitor Centre, Watersport and Beach Huts

Read More

Structural Assessment of Henley Masonry Arch Bridge

Read More

Northside Garages Structural Investigation

Read More

Pembroke Road Footbridge - Structural Investigation & Strengthening

Read More

Concept Design of Sedhiou Bridge and Roads Network

Read More

United Downs Deep Geothermal Power Plant

Read More

Wycombe Air Park- Data Centre

Read More

One West Point – Design of Support System for Cladding

Read More

Planning Permission for 21 Boston Road Townhouse Conversion

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

Helmsley Place-Steel Connections Design and Detailing

Read More

Planning Permission for New Warehouse, Ealing

Read More

Three Story Warehouse Steel Structure Design

Read More

Planning Permission for a Basement in a Conservation Area

Read MoreLondon Hippodrome Roof Extension – Structural Design and Detailing

Read More

St Peter’s Hospital Staff Accommodation, Piled Rafts Design

Read More

Grove Park Gardens 4 Storey Residential Development

Read More