Harwell Campus-Concrete Strengthening

Beta Scope

Beta Design Consultants scope for concrete strengthening comprised the following:

- Providing consulting advice to client during the conversion of a residential building to Class A offices.

- Evaluation of possible repair options for beams and slabs considering HPC and FRP.

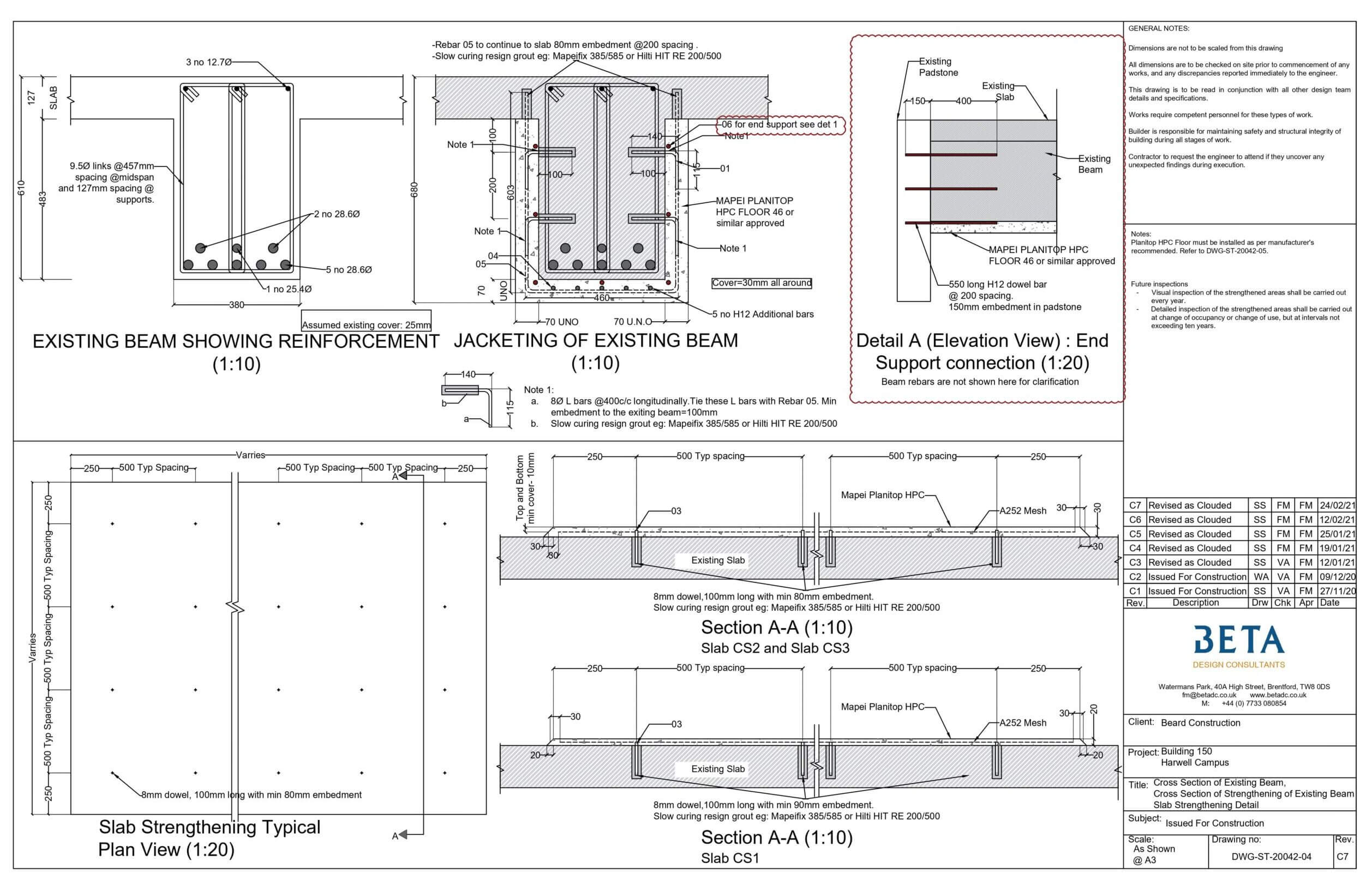

- Beam Strengthening in bending and shear using high performance concrete HPC jacket. This is the first use of high performance concrete in 3 side jackets that we are aware of.

- Slab Strengthening in HPC.

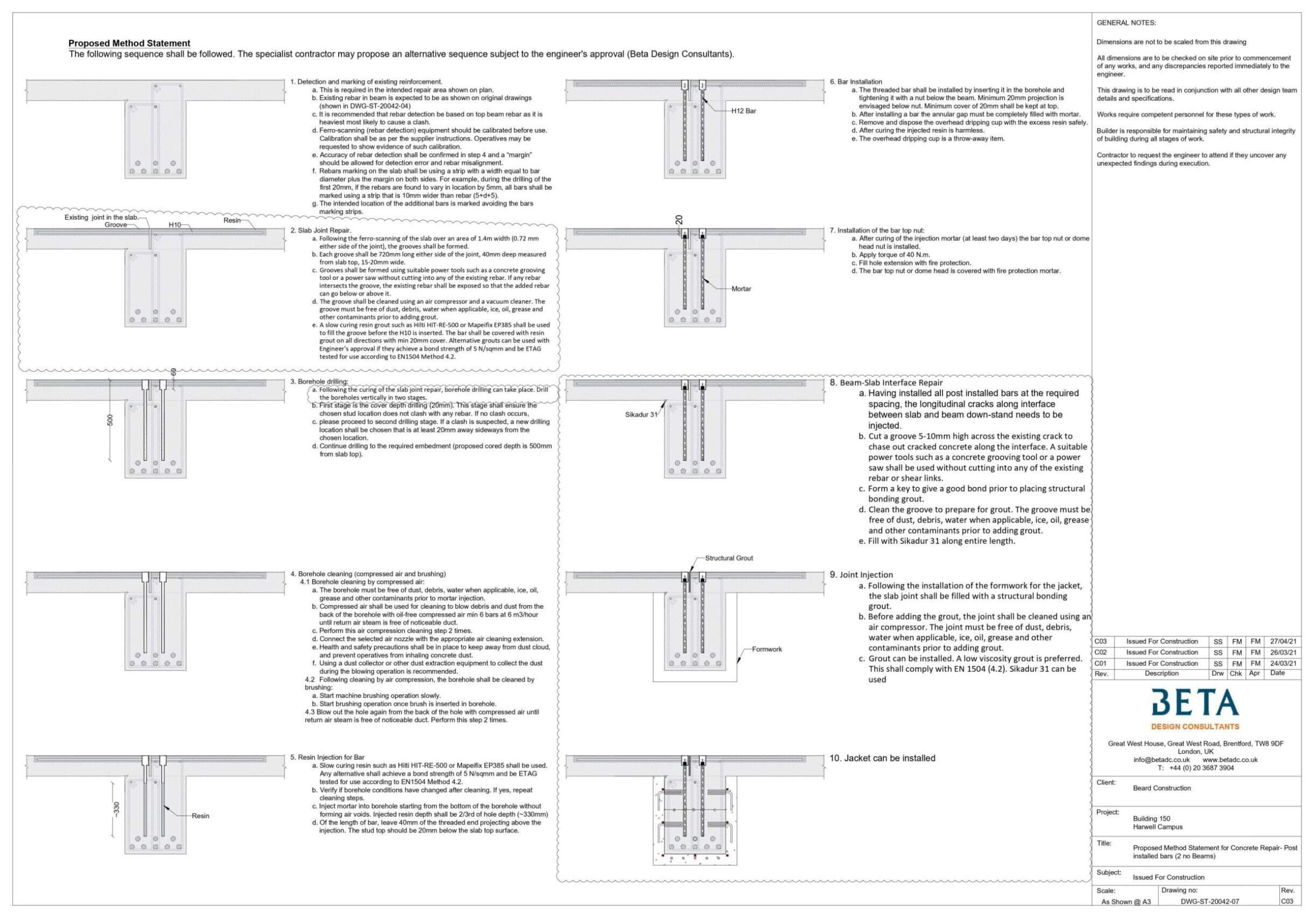

- Beam Strengthening in bending and shear to take into account the separation of the slab from the beam

- Design of additional slab strengthening to take into account the longitudinal joint in the slab

Background

Beta Design Consultants were commissioned by Beard Construction to advise on the structural strengthening design of concrete slabs and beams in the Harwell Campus, Building 150. The project Structural Engineers engineersHRW (eHRW) highlighted areas in the first floor slab and eight beams in the building that required strengthening. The scope of BDC included the design and specifications of repairs including method statements for the repairs.

Beta Approach

Slab Strengthening Approach

BDC engineers proposed the use of High Performance Concrete to strengthen the slab in the areas highlighted. The additional HPC layer is linked to the existing slab via dowels embedded in the existing slab and projecting 10-15mm into the HPC layer. The dowels ensured the whole system would act as one section and to ensure transfer of loads along the interface of concrete cast at different stages. HPC has very good bond strength to ensure transfer along the slip surface, however, dowels are added to ensure the transfer of the loads does not rely on bond and friction only.

Beams Strengthening Approach

BDC evaluated the potential use of Fiber Reinforced Polymers FRP in the strengthening of beams. However, after receiving the test results for the compressive strength, this option was dismissed. The existing concrete substrate strength is an important parameter for bond-critical applications of FRP. For FRP to develop and transfer the design stresses at the bond line, the concrete substrate should possess sufficient strength to transfer these stresses. And, in order for the concrete to provide the minimum bond strength of 200 psi (1.4 MPa), the compressive strength of concrete f‘c must be more than 2500 psi (17 MPa). The proposed solution is the use of High Performance Concrete in the strengthening, in the form of a jacket of flowable concrete on all three sides of the beams. The jacket is linked via dowels to the beam and the slab so that the whole system can act as one section and to ensure transfer of loads across the interface. HPC has very good bond strength exceeding the minimum values stated above and the use of the dowels will ensure the transfer of the loads does not rely on bond and friction only.

Strengthening Design Verification

BDC engineers developed bespoke calculations sheets based on first principles to check the sections considering the properties of HPC. The calculations were double-checked using a verification tool from the supplier. This ensures that the overall findings are checked for order of magnitude and also a similar outcome is confirmed using a different calculation method. For HPC design calculations, we opted for Mapei software tool (Planitop) to check our findings.

Background on HPC

High performance concrete (HPC) is characterized by a compressive strength of 60-120 MPa and 120-200 for ultra-high-performance concrete (UHPC). The inclusion of fibres with carefully selected fines and aggregates allows the HPC to offer superior performance properties such as durability, tensile ductility, toughness, hardness, impermeability, wear resistance, impact resistance, chemical resistance and resistance to repeated cycles of freezing and thawing. HPC was first developed in 1978 in Denmark by Hans Henrik Bache who was able to carefully select densified system particles containing homogenously arranged ultrafine particles to produce HPC. It is only recently, however, that concrete professionals have used HPC in thin layers to repair and strengthen columns, beams, slabs and bridge decks.

Compared with traditional jacketing with normal flowable concrete, the use of HPC offers the advantage of a smaller section as the high characteristic compressive strength and the possibility of using thin layers, along with the high bond, allows HPC to be a very attractive option. So HPC jacketing can offer advantages over traditional jacketing but its use is still a special activity and only highly trained concrete repair professionals are able to mix it and place it correctly. Unlike FRP use, HPC jackets can deal with much larger capacity increase demands and, in our experience, can be used to achieve more than double the capacity of existing sections.

There is currently no codified definition of UHPC. fib Model Code 2010 covers concrete up to a characteristic strength (fck) of 120MPa.

Challenges

The use of HPC jackets was a first in this application. BDC had attempted to use HPC jacekts in two projects before (CPS House Strengthening in Cheltenham and Brindleyplace Strengthening in Birmingham) but in both projects, the option was aborted due to technical or logistical restraints. In this project, BDC worked with Mapei UK technical team and Concrete Repairs Limited CRL teams to turn the design into a reality.

Two of the Beams conditions were found to be very poor as the concrete started to fall apart more than expected and we were required to come up with the new solutions. We visited the site again following poor and honeycombed concrete removal to assess the condition. The slab above these two beams showed separation of beam and slab along a horizontal plane below the slab indicating they were not acting together in the first place (contrary to design assumptions). BDC engineers proposed adding post installed bars that would be fixed to concrete using high bond expoy resin then pre-tensioned to tie the slab to the beam.

.jpg)