BP Deep Water Sump Assessment and Concrete Repair Design

Beta Scope

The scope included the following:

- Carrying out the detailed visual structural inspection of the deep water sump prior to plan shutdown. Our team carried out the inspection in the confined space after preparing all the risk assessment for BP approval.

- Preparing the scope for intrusive testing ( concrete strength and rebar corrosion) and NDT testing (chemical analysis, carbonation, and chloride ion content).

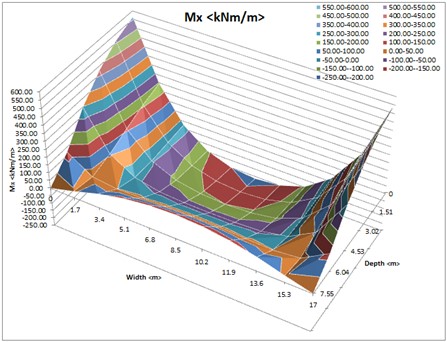

- The structural assessment of the sump walls which were working as unpropped cantilevers (RC walls subjects to earth pressure and surcharge leading to biaxial bending).

- Designing and specifying materials required for the structural repairs.

- Supervising repairs on site.

Background

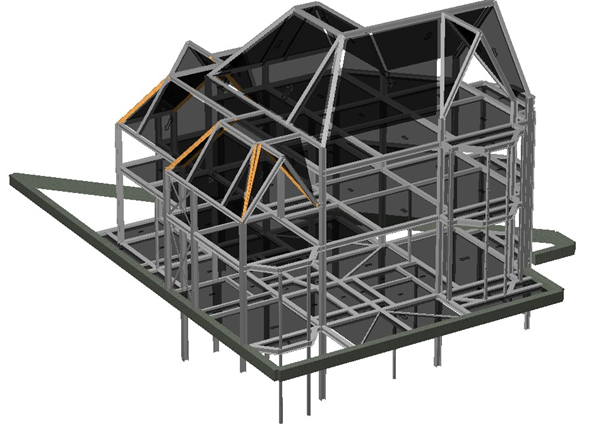

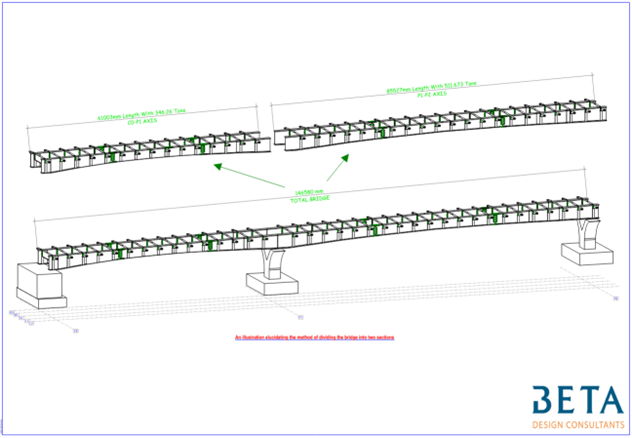

Beta Design Consultants acted as structural engineering consultant for Bechtel UK who were responsible for the asset refurbishment of BP Rosetta Gas Plant in Egypt (Giza Fayoum Gas Plant). We inspected, assessed and designed repairs and strengthening for the gas plant civil and structural facilities that required refurbishment including the deep water sump.

The client’s future plan for the plant required the assessment and life extension of all civil and structural facilities to ensure they have a service life of 25 years.

Challenges

The task presented unique challenges due to its location, maintenance history and client requirements. These challenges included:

- Strict programme to agree, tender and execute the works during a shutdown period of 12 months.

- Tight budget due to pre-forecast capital expenditure.

- Plant location on the Mediterranean coast, subject to a very corrosive coastal environment.

- Typically harsh petrochemical conditions (oily and chemical contaminants) affecting civil and structural facilities.

- The plant location in a seismic area (near Alexandria) meant all design had to consider seismic forces and seismic code requirements (ASCE 7-10 and AISC 341 Seismic Provisions).

Beta Solutions

Designing and specifying materials required for the structural repairs which included:

- scabbling of defective concrete

- Resin injection to seal cracks

- Application of corrosion inhibitors

- Application of bond agent

- Spraying concrete (shotcreting) and

- applying a protective coating.

Client: BP

Location: Egypt

Related projects

BP Heater Foundation Concrete Repair

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

BP GF Gas Plant – Slug Catcher Foundation Walls RC Repair

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More

United Downs Deep Geothermal Power Plant

Read More

Action Court Warehouse Extension

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

Concrete Strengthening for 8-10 Brindleyplace, Birmingham

Read More

Engine Yard Punching Shear Slab Strengthening

Read More

CPS House Jacketing to Strengthen RC Beams

Read More

Planning Application for Three Story Residential Building

Read More

Fulham Palace Road Temporary Works Design

Read More

Harwell Campus-Concrete Strengthening

Read More

Kennedy Institute Extension - Flat Slab Punching Shear Strengthening

Read More

Planning Permission for a Basement in a Conservation Area

Read More

Structural Repairs of a Listed Building

Read More

Orchard House – RC Column Strengthening using CFRP

Read More

NHS Staff Accommodation for St Peter’s Hospital in Chertsey, Piled Rafts Design

Read More

Stanmore House Strengthening

Read More

Bus Depot Electrification Harrow

Read More

Grove Park Gardens 4 Storey Residential Development

Read More

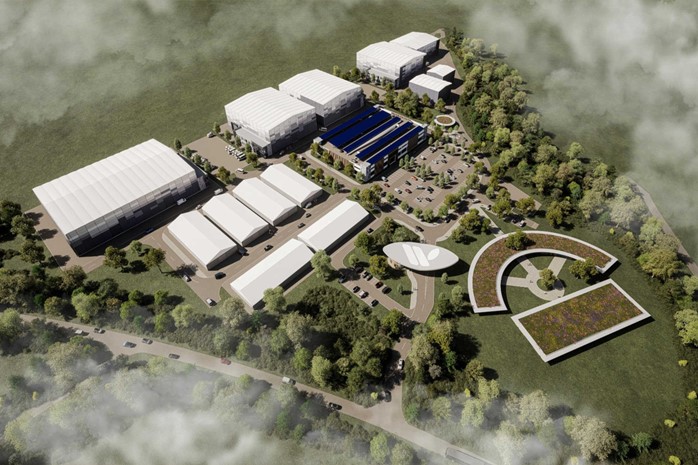

Design Development of Cité Administrative Koloma

Read More

Coast Drive Visitor Centre, Watersport & Beach Huts - Multi Discipline Consultants

Read More

Structural Assessment of Henley Masonry Arch Bridge

Read More

Northside Garages Structural Investigation & Refurbishment Options Appraisal

Read More

Peckham Arch Condition Survey & Life Extension Consulting Services

Read More

Pembroke Road Footbridge - Principal Inspection, Structural Investigation & Strengthening

Read More

RAAC Investigation and Structural Strengthening

Read More

Concept Design of Sedhiou Bridge and Roads Network

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

Stage 50 Wycombe Film Studios Village

Read More

Helmsley Place-Steel Connections Design and Detailing

Read More

Planning Permission for New Warehouse, Ealing

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

One West Point – Design of Support System for Cladding

Read More

Structural Design of 3 Storey Building

Read More