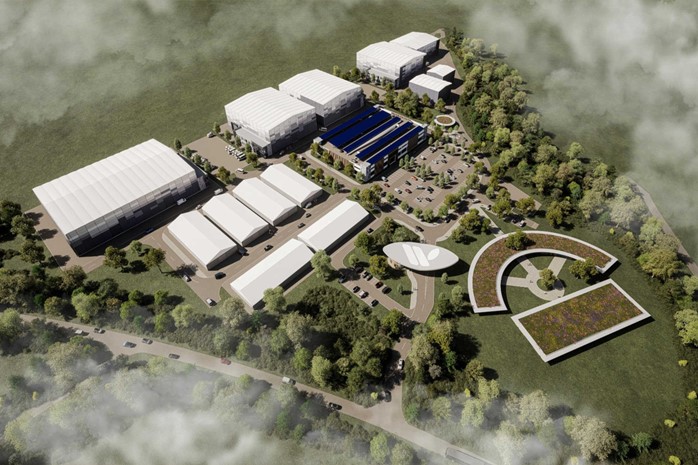

Beta Design Consultants have been supporting clients in the industrial sector, logistics sector and warehouse/storage sector for nearly 20 years. Our projects and design include support for clients in the heavy industries as well as logistics and storage clients.

Heavy Industrial/Chemical/Process Clients

Syngenta Chemicals (previously ICI)

Tata Steel (Port Talbot)

IFF Fragrances (Suffolk)

DSM (Darly, Glasgow)

Mapei (Speke, Liverpool)

Evonik (Turkey)

Logistics/Warehouses Clients

Amazon (Ireland, Germany, Spain)

Do & Co (Heathrow)

Polybags PG Group (London)

Quick Skip Hire (London)

The Role and Added Value of Beta Design Consultants to Logistics and Industrial Projects

Our civil and structural engineers address the unique demands of these facilities, including heavy loads, large spans, operational efficiency, and adaptability for future requirements. Beta Design Consultants also respond to an increasing set of challenges related to value for money, carbon footprint and lifecycle assessment. Below are the key design considerations that Beta Civil Structural engineers consider when supporting logistics and industrial buildings:

1. Load-Bearing Capacity

- We design for heavy machinery, storage racks, pallets, and equipment. In some cases, we have to design for the upgrade of existing facilities to take increased loads and design strengthening to support expansion and modification.

- We account for dynamic loads from moving vehicles like forklifts, cranes, or conveyors.

- We design for point Loads and reinforce floors to handle concentrated loads from racks and equipment footings.

- We design for impact Loads caused by accidental collisions, especially in high-traffic areas. In some cases, we design strengthening and repairs following the damage caused by impact.

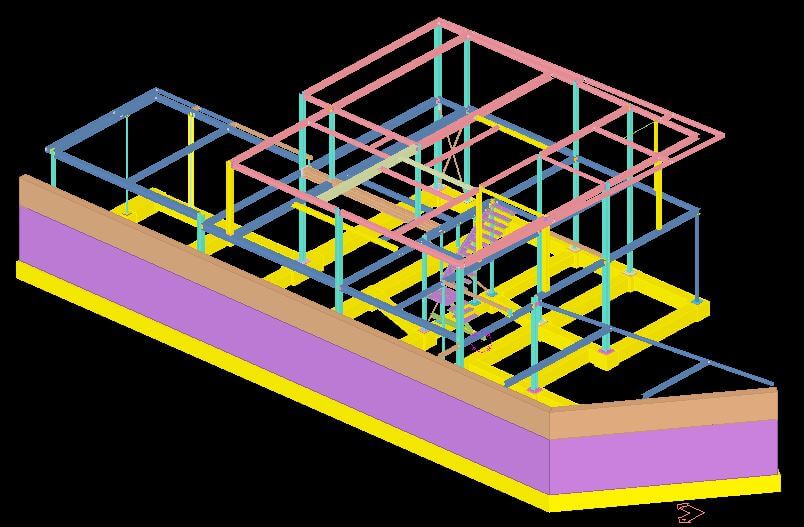

2. Large Clear Spans

- Many clients request large, column-free spaces to maximize the usable area for equipment, storage racks, and vehicle movement. In some cases, we are invited to provide advice on assessing the impact of removing an existing column to double the column-free span and we strengthen the superstructure or the foundations accordingly.

- We use structural systems like steel frames, pre-engineered buildings (PEBs), trusses, or portal frames to achieve large spans efficiently.

- We optimize roof and beam spacing to reduce material usage without compromising strength.

3. Floor Design

- We ensure high load-bearing capacity for industrial floors, often requiring reinforced concrete floors that are designed for the correct use and functional requirements in accordance with the applicable structural standards.

- We specify flat, durable surfaces with high resistance to wear and tear.

- We detail the quality control requirements to ensure precise tolerances for flatness and levelness, especially in warehouses with automated guided vehicles (AGVs) or high-bay storage. Construction/workmanship defects that result in deviation from these tolerances can negatively impact the operation of forklifts.

- We design and specify jointless construction or minimized joints to reduce maintenance and increase operational efficiency. The introduction of steel-fibre reinforced concrete floors as well as advances made in high performance concrete has resulted in large pours of concrete being viable without joints.

- We specify expansion joints to handle thermal movements and prevent cracking.

4. Foundations

- We prepare the brief and coordinate the soil investigation and lab testing to confirm the allowable bearing pressure of the site and organize investigations to identify the type of existing foundations when working with existing assets.

- We design foundations to support heavy loads and equipment, considering soil conditions and settlement.

- We typically adopt shallow foundations (e.g., isolated or raft footings) when soil conditions allow. Where this is not possible, we design deep foundations (e.g., piles or piled rafts) following the recommendations of geotechnical reports and in accordance with the load take-down that we undertake.

- We consider the risks of differential settlement that may be caused by heavy equipment or racking loads.

5. Roof and Cladding Systems

- We design lightweight and durable roofs for large spans, minimizing intermediate supports.

- We design the supports required for cladding in consultation with the client, the architect and the local supply chain.

- We ensure proper drainage with sufficient slope and rainwater systems to prevent ponding.

- We allow for thermal insulation, ventilation, and provisions for solar panels, skylights, or rooftop equipment.

6. Wind and Seismic Loads

- We design for wind pressure, particularly in areas prone to high wind speeds.

- We ensure roof and wall cladding are adequately secured to resist wind uplift.

- In the UK, this is rarely required, but in Europe, Middle East and the Americas, we design for lateral forces from earthquakes, ensuring stability through braced frames or moment-resisting frames.

- We provide sufficient ductility and energy dissipation mechanisms to resist seismic forces.

7. Material Selection and Specifications

- Structural Steel Use in Industrial and Logistics Buildings:

- We widely use steel for its high strength-to-weight ratio and ability to support large spans.

- We prefer steel for the feasibility of pre-engineered assemblies and modular steel components which can speed up construction and reduce construction and installation costs.

- Reinforced Concrete Use in Industrial and Logistics Buildings:

- We use RC for its durable slabs and floors, foundations, and walls.

- We may combine RC with steel for composite floors as these do not require formwork and can support considerable industrial and storage loads.

- Cladding Specification in Industrial and Logistics Buildings:

- We use lightweight, insulated panels for walls and roofs to improve thermal performance and reduce weight.

- We consider the supports of the selected cladding panels and detail the secondary steel required for support with cleats to fix to the primary structure.

8. Fire Safety

- We ensure compliance with fire safety regulations by:

- Specifying fire-resistant materials for structural members and specifying the required fire rating in accordance with the use and legal requirements dictated by the Building Regulations.

- We specify the method to achieve the required structural fire resistance, whether that would be specifying the cover or minimum dimensions of concrete elements, or specifying coatings for steel elements, or specifying boards/gypsum boards to give the required fire resistance.

- We advise on the installation of fireproof coatings or protective cladding on steel members and specify the fixings.

- We coordinate with the fire engineer and fire risk assessors on fire exits, fire walls, and sprinkler systems.

9. Drainage and Environmental Considerations

- We design adequate site drainage to prevent waterlogging, especially for outdoor storage or loading/unloading areas.

- Incorporate sustainability measures like rainwater harvesting, energy-efficient materials, or green roofs.

- We design process water systems, also referred to close networks and advise on the maintenance, operation and discharge requirements.

10. Flexibility and Future-Proofing

- We design adaptable spaces that can be reconfigured for future operational changes. This is a key consideration for multiple clients and we advise them how they can balance capital investment at this stage with future potential operational needs.

- We provide layout options and can offer market engagement to obtain budget estimates regarding cost impact of various configurations.

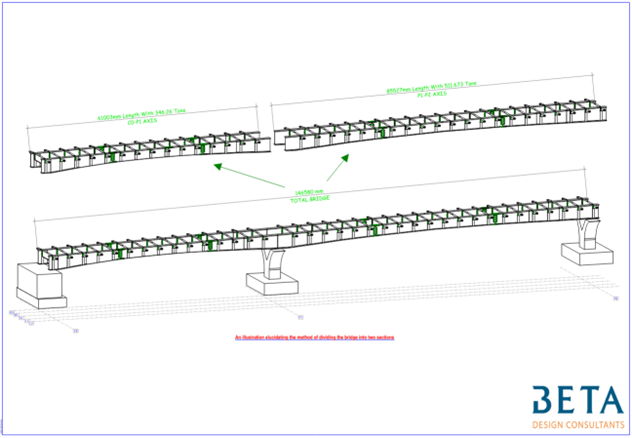

- We specify and design modular structural systems to facilitate expansion or modification.

11. Vertical Storage

- For high-bay warehouses, our structural engineers ensure:

- High racking systems are structurally integrated with the building frame.

- Proper seismic bracing for racks and supports is designed and specified.

- Floors must support point loads from racks and material-handling systems.

12. Loading and Unloading Areas

- We design and allow for reinforced docks, ramps, and floors at loading/unloading areas.

- We incorporate dock levelers, dock shelters, and other elements for operational efficiency.

13. Thermal and Environmental Control

- Our design engineers incorporate thermal insulation in the roof and walls to maintain controlled temperatures.

- We coordinate with MEP consultants to ensure proper ventilation for smoke, heat, or fumes in industrial buildings.

- We coordinate with MEP to ensure HVAC systems are designed and coordinated in tandem with structural layouts for maximum efficiency.

14. Specialized Requirements

- Cranes and Hoists:

- We design for overhead crane systems, gantry cranes, or hoists, accounting for dynamic loads and deflections.

- Mechanical Systems:

- We accommodate equipment like conveyors, HVAC, and exhaust systems in the design.

- Explosion-Proof Design:

- For industries handling hazardous materials, we design and specify explosion-proof walls, venting systems, and blast-resistant structures.

15. Compliance with Codes and Standards

- Adhere to local building codes (e.g. Eurocodes, IBC or local standards) and industry-specific regulations.

- Ensure compliance with health, safety, and environmental standards.

16. Civil Structural Design of Upgrades

- We support clients undertaking upgrades, maintenance, refurbishment programmes by undertaking defects structural surveys, investigations, NDT and intrusive testing, assessments and repair specifications.

- Our services also include the design of strengthening, vertical and side extensions of existing industrial assets or existing warehouse.

- We manage the tendering process, evaluate bidders.

- We can offer site supervision and project management of upgrade schemes.

By addressing these considerations, the civil structural design team at Beta Design Consultants ensures that logistics and industrial clients are given solutions that are safe, durable, and functional for current and future operations.