Civil and Structural Engineering Consulting Services

Beta Design Consultants play a critical role in supporting our power & energy clients during the design and construction of power, oil and gas facilities. Our management team and design consultants have been supporting operators and EPC contractors around the world on projects upstream as well as processing facilities downstream. We have also been involved in a variety of roles including PMC, pre-feed, FEED, EPC and asset refurbishment stages. Please refer to our clients page for a list of our energy clients which include Bechtel, BP, DNV, KBR, Orsted, Wood Group and a long list of supply chain partners.

Projects include:

| Beta Client | Project | Operator/End Client | Period |

| Exergy SRL | United Downs Cornwall Power Plant | GLE | 2023-2024 |

| Alghanim | Duqm Power Plant | CUC, Oman | 2022 |

| Belltown Power | Tyr Gwent Wind Farm | Wales, UK | 2021 |

| Orsted | Renescience Energy from Waste Plant | Northwich, UK | 2020 |

| Bechtel | Giza Fayoum Asset Refurbishment | BP, Egypt | 2018-2019 |

| West Nile Delta WND | BP, Egypt | 2015-2018 | |

| Shell Franklin PMC | Shell, USA | 2014-2015 | |

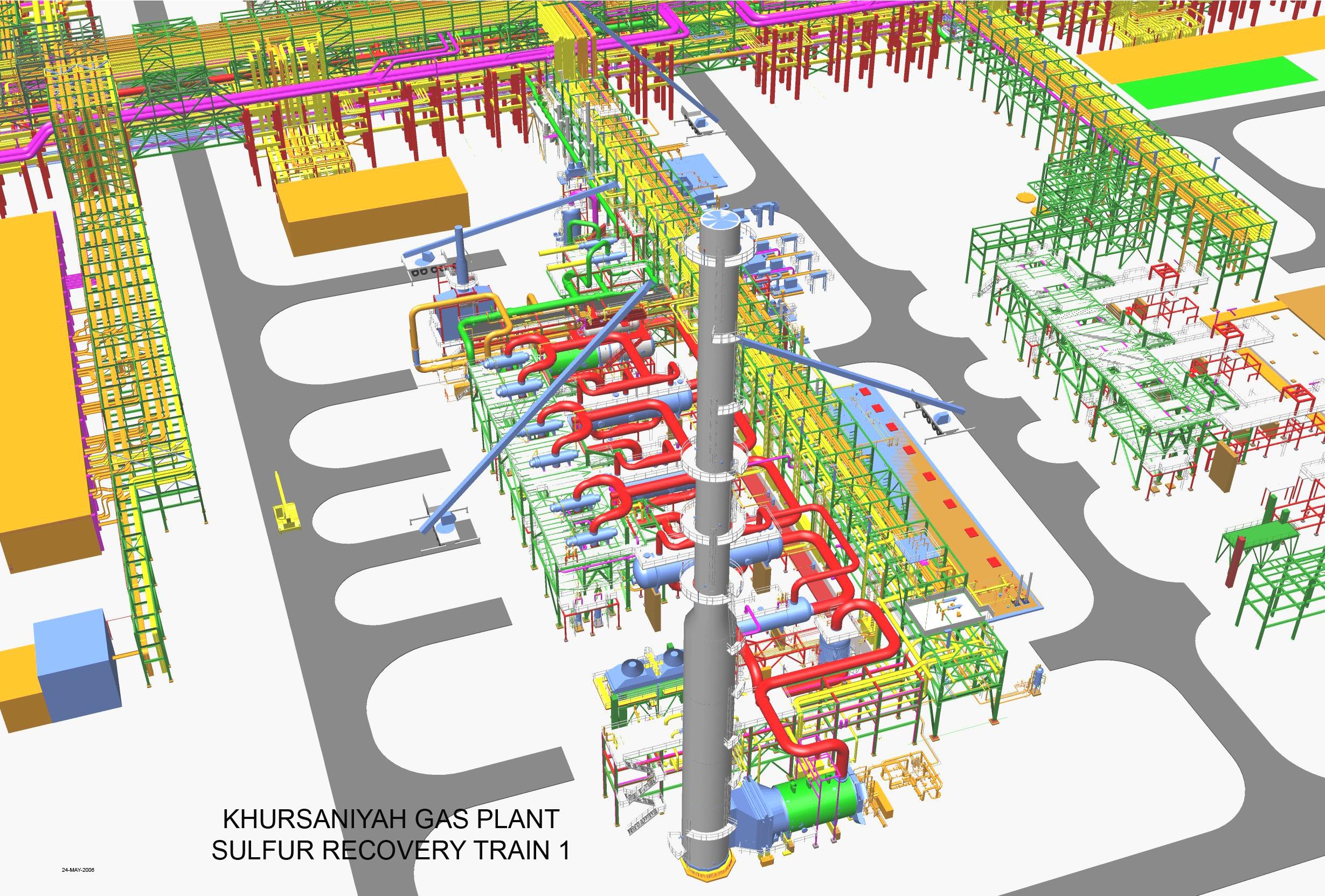

| Khursaniyah Gas Plant EPC | ARAMCO, KSA | 2006-2009 | |

| Takreer Ruwais Refinery Extension FEED | ADNOC, UAE | 2009 | |

| Angola LNG Plant | LNGA, Angola | 2009 | |

| Wood Group | Ivar Aasen Offshore Platform | Det Norske | 2013-2015 |

| KBR UK | Shah Deniz 2 Offshore Platform | BP, Azerbaijan | 2013 |

| DNV GL | Structural Integrity Management Offshore Platforms | BP, BG, CSL, Premier Oil | 2011-2013 |

| KBR | Gorgon Offshore LNG Project EPC | Chevron, Australia | 2010- 2011 |

| Shaw UK | Hassi Messaoud LPG Project EPC | Saipem, France | 2009-2010 |

Our consulting services include support in different forms and the responsibilities of our consultants typically include:

- Site Selection and Evaluation: Beta Design Consultants have been involved in assessing potential sites for oil and gas facilities, considering factors such as geology, soil conditions, environmental impact, and accessibility. During the BP West Nile Delta initial stages, our consulting engineers visited two sites with the EPC contractor and evaluated the advantages and disadvantages of each site making a recommendation to the client on the preferred option along with proposals to deal with the site challenges and maximize the advantages of the site. One of the main advantages of the recommended site was its proximity to an existing site so the advantages of tapping into the existing infrastructure were clear. However, we also identified risks and measures that should be taken to ensure this is planned properly via utility surveys, trial pits and a comprehensive programme of topographic and soil investigation.

- Conceptual Design, PRE-FEED and FEED: Beta Design Consultants support clients develop the initial design concepts for the civil and structural facilities, turning the ideas of the process and layout teams into meaningful plot plans that can be used to progress the design to next stages. During Front End Engineering FEED studies and pre-FEED studies, we consider the functional requirements, safety standards, and regulatory compliance. The outcome would be conceptual designs, indicative drawings and high-level estimates for the quantities of civil and structural activities. These deliverables can be used for initial estimates and budget/programme planning. We supported ADNOC and Bechtel during the FEED study for Ruwais Refinery Extension. We supported Exergy during the Concept Design of United Downs Power Plant project.

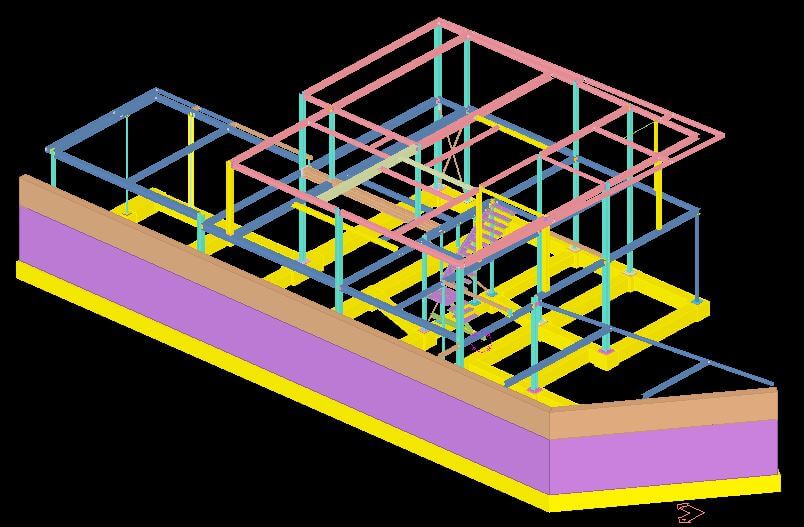

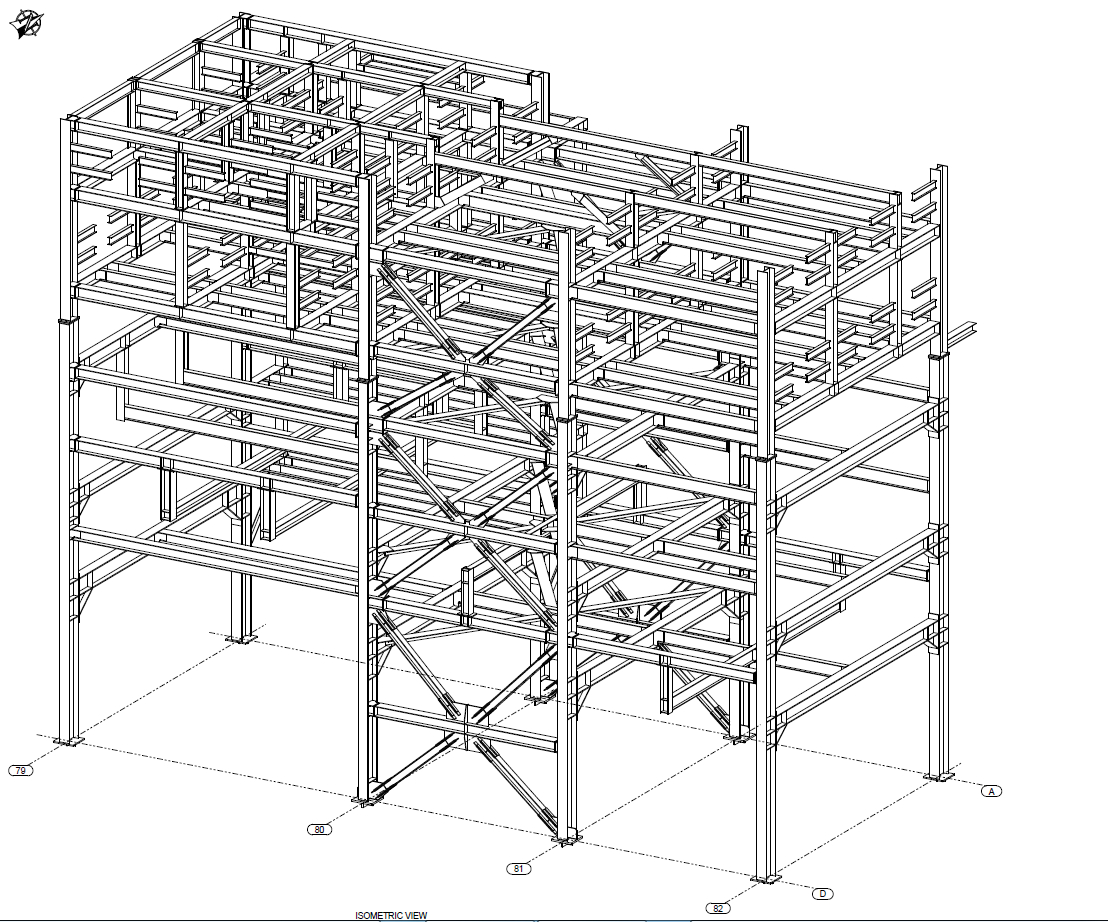

Figure 1: FEED Level Model of Crude Unit Structures for Ruwais Refinery Extension - Structural Analysis and Design: Beta Design Consultants support clients by analyzing the structural requirements of the facility and designing the appropriate structural systems to support the loads imposed by equipment, piping, and environmental conditions, including wind, seismic, and snow loads. This service has been offered as part of an engineering, procurement and construction EPC packages offered to contractors. It has also been offered to clients directly so that a traditional procurement route can be followed.

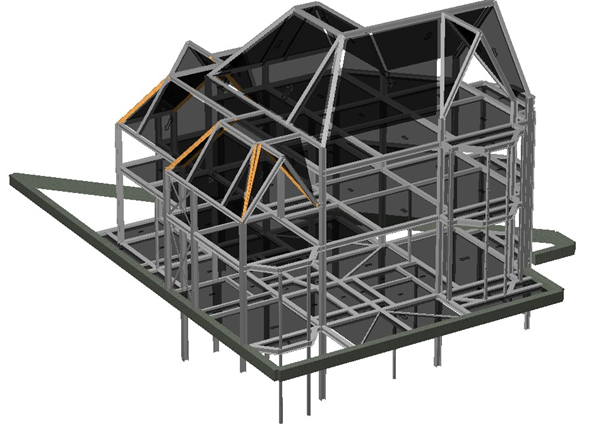

Figure 2: Design of a typical oil and gas pipe-rack - Foundation Design: Beta Design Consultants have designed foundations for various structures and oil and gas facilities such as storage tanks, processing equipment, and buildings, ensuring stability and durability for the given soil conditions. The design of retaining walls, large wastewater treatment pits and piled foundations is also offered as part of our ground engineering services.

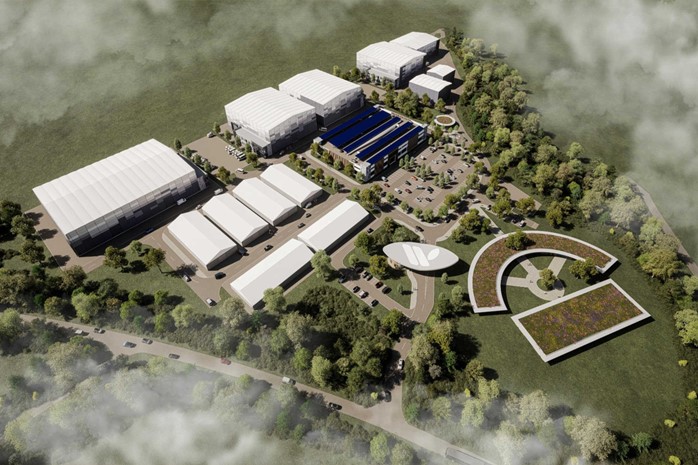

Figure 3: Equipment and Racks Foundations protected with membrane - Roads Design: Beta Design Consultants support clients and process/layout engineer design the layout of piping systems within the facility and specify the supports needed to ensure the integrity and reliability of the piping network. We also design the infrastructure of roads and utilities needed for construction, operation and maintenance access. Roads and Pavement design must take into account the operational safety, access for fire-fighting, access of heavy vehicles as well as access for installation during construction.

Figure 4: Structures, Foundations, Drainage and Roads Integrated with Equipment in one 3D Model - Underground Services Design: Beta Design Consultants support clients in the design of all types of underground services including process water drainage (closed-system), oily water drainage and separation, fire fighting pressured-system, electricity cable trenches/ducting and pits, telecoms cable trenches/ducting and pits as well as rainwater drainage. This may be combined with a sustainable drainage strategy SuDS design to include measures such as attenuation tanks, soakaways, landscaping and greening. In some cases, Beta Design Consultants manage the compliance process making applications to the local authorities and coordinating the process of getting approvals.

Figure 5: Design of underground services in oil and gas facilities is crucial to avoiding clashes - Asset Refurbishment and Integrity Assessment: We are specialists in the assessment and strengthening of structures in oil and gas facilities. Steel structures may suffer from corrosion and coating damage from exposure to harsh environmental conditions. Concrete structures can also suffer from rebar corrosion, carbonation, chloride attack and water ingress. Foundations can be exposed to chemicals from the process, chlorides in coastal environments, carbonation due to emissions, cold and hot climate and water ingress. We carry out inspections, structural assessments, foundations reuse studies, structural strengthening studies, life extension studies and cathodic protection design. We use non-destructive testing methods combined with limited intrusive inspection to diagnose structural defects and design the structural repairs and interventions accordingly.

Figure 6: Oily water separation pit in a corrosive environment - inspected and repaired by our team - Safety and Risk Assessment: Beta Design Consultants support clients in regular safety reviews and risk assessments to identify potential hazards and develop measures to mitigate risks associated with the operation of the facility. Our consultants contribute to Hazards and Operational (HAZOP) studies by informing process safety of options to reduce risks and effective methods to communicate residual risks.

- Regulatory Compliance: Beta Design Consultants advice clients of applicable Local, National and International regulations. We ensure that the civil and structural design of the facility complies with all relevant regulations and the latest applicable codes of practice, including those related to safety, environmental protection, and construction codes. We are proud to have worked on projects in most jurisdictions including:

- The United States (Shell Franklin Petrochemical Facility and Wood River Refinery).

- The Caribbean (Trinidad and Tobacco Offshore Platform, Cayman Islands).

- Chile (Design of Raised Access Flooring in a data centre / energy facility).

- The United Kingdom.

- Ireland and Continental Europe (Belgium, France, Germany, Italy, Netherlands, Norway, Poland, Spain, Sweden).

- Azerbaijan and Turkey.

- Far East (Indonesia, Malaysia, Philippines, Singapore).

- Kingdom of Saudi Arabia KSA, Kuwait, Oman, United Arab Emirates UAE.

- Algeria, Angola, Egypt, Guinea, Nigeria, Senegal, South Africa, Tunisia.

- Australia - Construction Support: Beta Design Consultants provide support during the construction phase, including reviewing construction plans, responding to requests for information, and conducting site visits to ensure that the construction meets the design specifications. This may include:

- The technical evaluation of contractors and subcontractors

- Appointing a representative or a technical authority to support clients in conducting pre-appointment surveys to contractors yards or suppliers production facilities.

- Developing evaluation criteria and a matrix for the fair assessment of various bidders.

- Developing bills of quantities, forms of contract and construction programs.

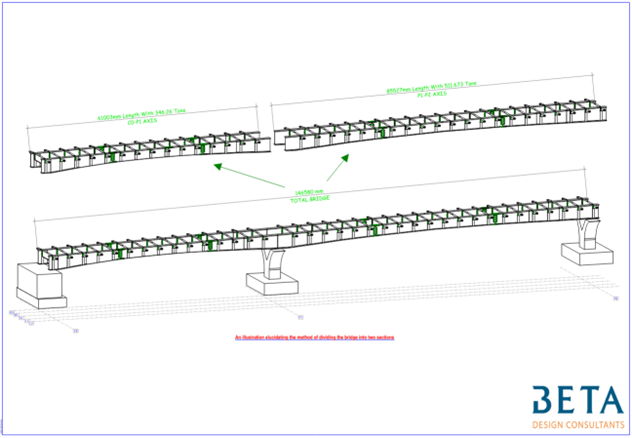

Figure 7: Steel Frames Complying with AISC 341 Seismic Provisions & AWS D1-8 - Quality Control and Assurance: Beta Design Consultants implement quality control and assurance measures to ensure that the construction materials and methods meet the required standards and specifications. In some cases we have developed inspection and testing plans ITPs for the contractors to adopt. In other cases, we have reviewed proposed ITPs to ensure that the inspections and quality control measures are planned and executed to meet clients requirements. We have also supported by lending technical assistance to conduct pre-delivery inspection visits.

- Project Management Consultancy: Beta Design Consultants take on project management responsibilities, coordinating with other engineering disciplines, contractors, and stakeholders to ensure the successful execution of the project within budget and schedule constraints. The scope of this service depends on clients needs and may include technical support to the project manager to full project management of a certain package. In 2018, we were appointed in the project management role of a full package of structural steel (16000 Tonnes) from fabricator appointment to financial close out to a value of $40M.

You can rely on our consulting civil and structural engineering to deliver the design and construction support for your project oil and gas facilities, ensuring that they are safe, efficient, buildable, and compliant with regulatory requirements.