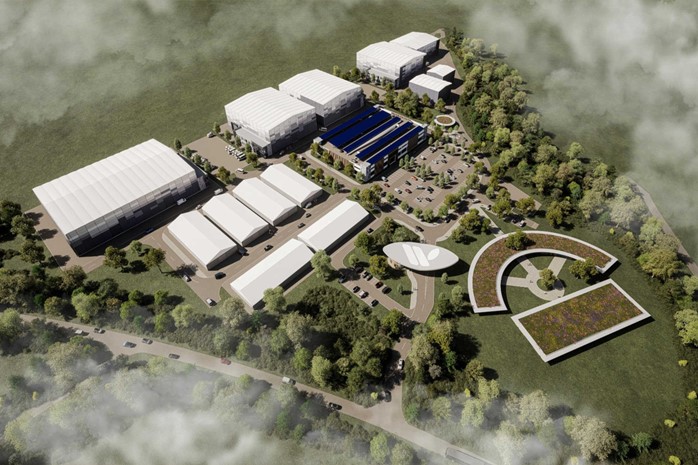

Beta Design Consultants support their clients in providing geotechnical engineering services as well as structural engineering services related to the design and temporary works design of shoring systems for all types of deep excavations.

Our consulting geotechnical engineers play a crucial role in deep excavation projects by providing expertise and guidance throughout the various stages of the project. Some key responsibilities and contributions of our geotechnical engineers include:

- Site Investigation: Our consultants would prepare the brief and then coordinate a comprehensive site investigations to assess the soil and rock properties, groundwater conditions, and other geotechnical parameters required for the design and during construction. They analyse the data collected from soil testing, geophysical surveys, and laboratory testing to understand the soil behaviour and potential risks associated with the excavation. Planning and proper briefing is crucial prior to the mobilization of the drilling and investigation teams. The right number of trial pits, location, number and depth of boreholes and field tests all need to be planned taking account the planned activities.

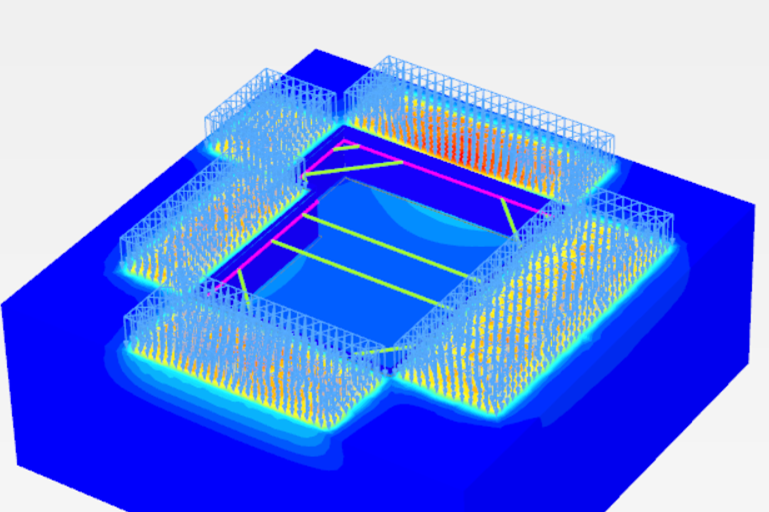

- Design of Excavation Support Systems: Our geotechnical engineers design and analyse the excavation support systems, including retaining walls, shoring systems, bracing, and underpinning techniques. They consider factors such as soil strength, stability, groundwater pressures, and anticipated loads to determine the appropriate support system that ensures the stability of the excavation.

- Stability Analysis: Our geotechnical engineers perform stability analyses to assess the potential for slope failures, soil movement, and settlements during the excavation process. We consider various factors such as lateral earth pressures, groundwater effects, and the interaction between the support system and the surrounding soil to ensure the safe and stable excavation.

- Ground Improvement Techniques: Our consulting geotechnical engineers evaluate and recommend ground improvement techniques when the soil conditions are not suitable for excavation. This may involve methods such as soil stabilization, compaction, preloading, or grouting to improve the soil strength and stability.

- Monitoring and Instrumentation: Our geotechnical engineers establish monitoring programs to track the behaviour of the soil, groundwater, and structures during the excavation process. They install instruments such as inclinometers, settlement gauges, piezometers, and strain gauges to measure deformations, groundwater levels, and other parameters. Monitoring helps in early detection of potential issues and allows for timely corrective measures.

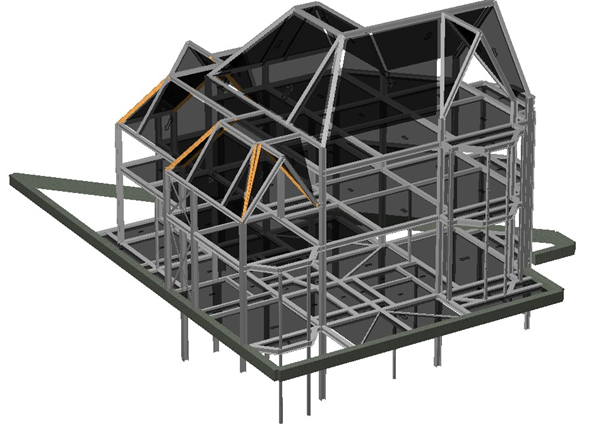

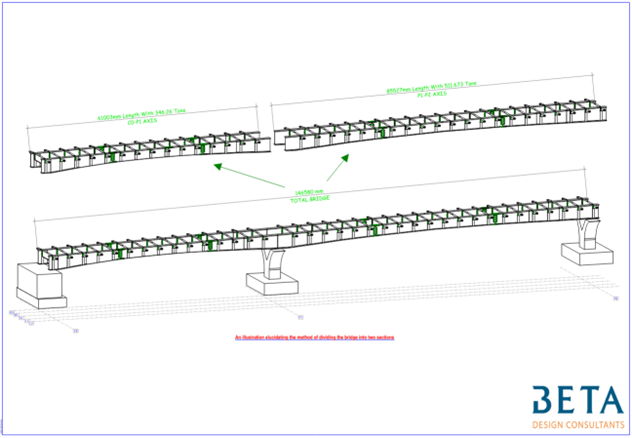

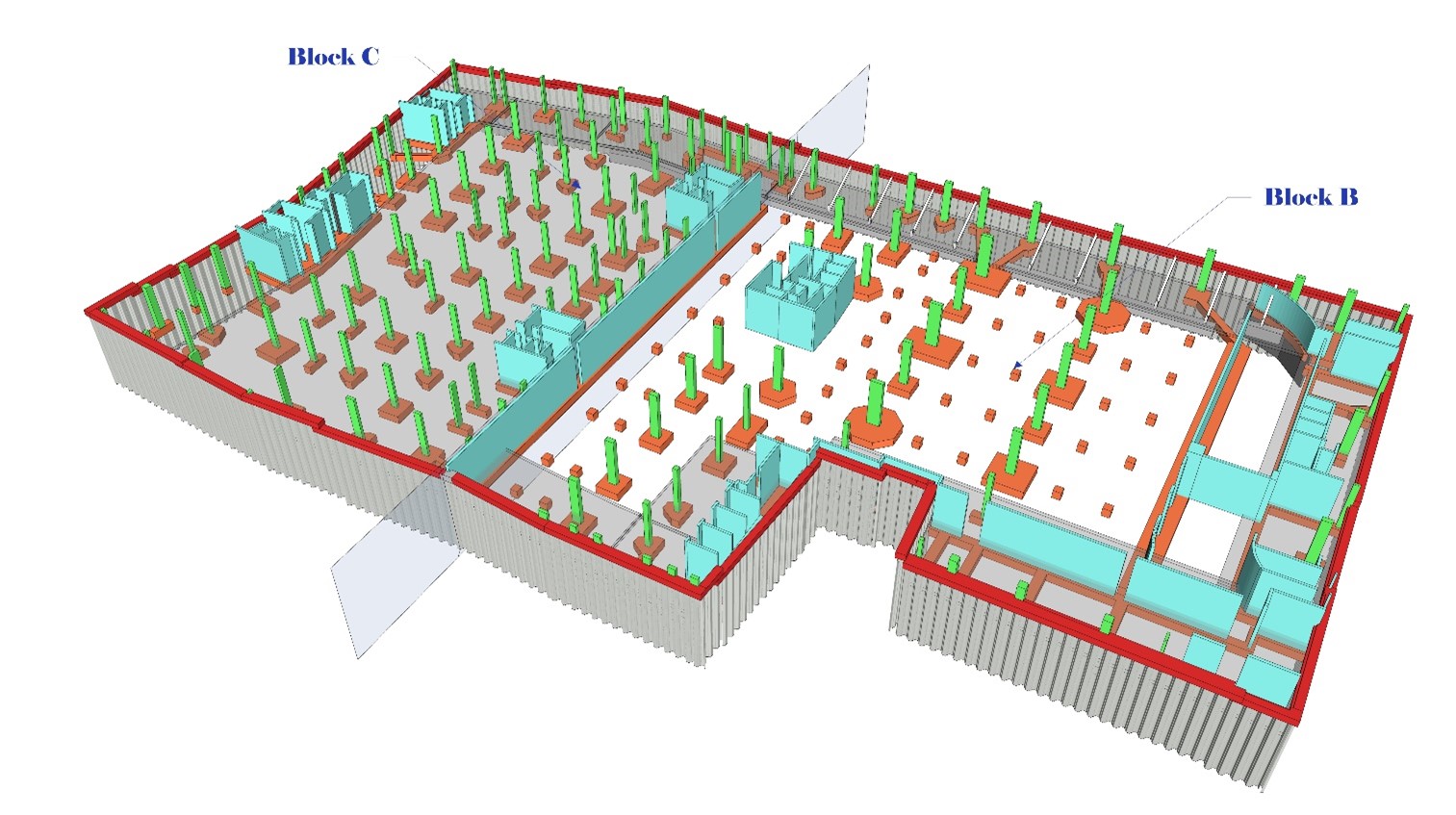

- Construction support services: these include but are not limited to the detailed design of temporary props connections, detailed design of props foundations and preparing full building information modelling BIM models to carry out clash checking. The BIM model can also be used for digital fabrication of temporary props by updating the model to consider surveyed dimensions so props are manufactured according to surveyed dimensions as opposed to theoretical lengths that result in extra work on site.

Failure Examples in Deep Excavations:

Our consulting engineers ensure that clients and contractors are made fully aware of risks associated with deep excavations so proper mitigation measures are in place. Our consulting geotechnical engineers try to address various failure modes, including:

- Slope Failures: If the excavation slopes are not properly designed or supported, they can experience slope failures due to excessive soil movement or instability. This can lead to collapses, landslides, or localized failures within the excavation.

- Groundwater Inflow: Inadequate management of groundwater during excavation can lead to uncontrolled inflow, causing instability, erosion, and potential failure of the excavation support system or adjacent structures.

- Settlement: Excessive settlement can occur if the excavation induces significant soil disturbance or if the underlying soils are compressible. This can result in differential settlement and structural damage to nearby buildings and utilities.

- Heave and Lateral Soil Movement: Poor soil characterization and analysis can result in unexpected soil heave or lateral soil movement during the excavation process. This can damage adjacent structures or cause stability issues.

Mitigation Measures for Deep Excavations:

To mitigate the risks associated with deep excavations, our consulting geotechnical engineers work with the clients and the contractors to adopt one or more of several measures that can be taken on site, including:

- Adequate Support Systems: Implementing appropriate excavation support systems such as retaining walls, shoring, or bracing structures can provide stability and prevent slope failures. It is important that such temporary works are designed for realistic loading and based on knowledge of contractor capabilities and endorsed by a competent contractor. Many issues may arise along interfaces if works are sub-contracted so communication and site supervision are key.

- Groundwater Control: Implementing effective groundwater control measures, such as dewatering techniques or groundwater cut-off walls, can manage groundwater levels and prevent excessive inflows.

- Ground Improvement: Employing ground improvement techniques like soil stabilization or compaction can enhance the soil's strength and stability, reducing the risk of failure.

- Monitoring and Instrumentation: Regular monitoring and instrumentation programs should be established to detect any signs of instability, deformations, or excessive settlements. This allows for timely intervention and corrective measures.

- Construction Sequencing: Proper planning and sequencing of excavation activities, including staged excavation, can minimize the risks associated with deep excavations. The construction method statement need to be discussed and agreed with involvement of permanent works engineer, temporary works engineer and contractor/subcontractor teams.

- Geotechnical Design Review: Regular review and assessment of geotechnical designs by experienced geotechnical engineers can help identify potential issues and optimize the design to ensure stability and safety.

It is important to note that every excavation project is unique, and the mitigation measures should be tailored to the specific site conditions, project requirements, and potential risks identified through detailed geotechnical investigations and engineering analysis.