Beta Design Consultants has been involved in the design of strengthening using composites such as CFRP, UHM CFRP, GRP and FRCM since 2019. Our team has been instrubmental in establishing feasibility, planning the repairs and strengthening, carrying out detailed design of CFRP/FRCM and preparing installation method statements. We then supported clients during the procurement to find competent installation teams and supervised installation where necessary. We carried out testing and specified required quality control requirements.

We then advised clients on the future inspection and maintenance of the structures strengthened with composites. This included buildings, infrastructure assets, bridges and tanks.

1. CFRP (Carbon Fibre Reinforced Polymers)

Strengthening using Carbon fibre reinforced polymers, or CFRP, involves using composite materials developed from natural carbon fibre to reinforce, and repair structural elements. Strengthening materials made from CFRP are extremely lightweight, usually 1.2-1.4mm thick or even less sometimes, which means they can be used to support a wealth of structural strengthening and rehabilitation jobs. These are either mounted on the surface or near the surface (in grooves). Surface mounted CFRP use a thin layer of adhesive to bond the carbon fibre to the substrate. Near surface mounted (NSM) carbon fibre laminates or bars can also be used instead of surface-mounted laminates of wraps. The adhesive is a thicker block than the thin layer used in surface mounted and the interface area between the FRP and adhesive is potentially smaller than that between the adhesive and the concrete (as the groove has a larger perimeter than the bar resulting in bigger interface area).

ADVANTAGES AND APPLICATIONS

Due to their durability, high tensile strength and extremely light weight, CFRP can be used for:

- Corrosion-related repair

- Seismic retrofit (rehabilitation of a building's connections)

- Structural preservation

- Flexural strengthening of beams and slabs

- Shear strengthening of beams and slabs

- Axial strengthening of columns

Beta Design Consultants have been involved in the flexural, shear and axial strengthening using CFRP on various retail, data centre, aviation and infrastructure projects all over the UK.

© Beta Design Consultants

2. FRCM (Fibre Reinforced Cementitious Matrix)

BACKGROUND ON FRCM Use in Strengthening

FRCM systems consist of fibres embedded in a cementitious matrix. The function of the fibres is to carry tensile stresses. In FRCM composite systems, the fibre sheets or fabrics that are typically used in FRP are replaced with open fabric meshes in which the rovings are assembled in at least two directions (generally orthogonal) by means of weaving, knitting, tufting, or braiding. “Closed” fibre fabrics are not suitable because the cementitious matrix cannot penetrate and impregnate the fibre filaments. However, the open structure of the fabric meshes provides higher matrix-reinforcement interface area which is needed to achieve the composite action between the matrix and the reinforcing system. Typically, the mesh openings do not exceed 0.75 inches. The rovings are typically coated with resin to improve the bond to the mortar matrix, enhance the long-term durability and improve the load transfer among the roving filaments. The fabric meshes are typically made of carbon, alkali-resistant glass, basalt, polymeric fibres or hybrid systems.

ADVANTAGES AND APPLICATIONS

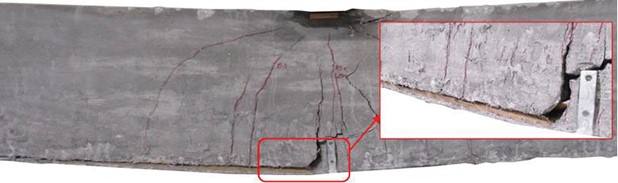

Beta Design Consultants have used FRCM systems in multiple applications as they offer are a viable option for flexural and shear strengthening of concrete and masonry members. In general, the strength increases in reinforced concrete beams or slabs, and unreinforced masonry walls strengthened with FRCM systems are comparable to those of similar elements strengthened with FRP. However, their overall behaviour is slightly different. In the case of FRP-strengthened elements, failure is typically due to the debonding from the substrate. This type of brittle failure does not generally occur with FRCM-strengthened elements, where less brittle “unzipping” failures occur due to progressive slippage of the fibres within the cementitious matrix or delamination at the fibre-matrix interface. Fibre slippage across a flexural or shear crack is caused by the gradual loss of bond between fibres and matrix and/or by the gradual rupture of the fibres. Fiber delamination generally occurs when multiple layers of FRCM reinforcement are used and is preceded by large fibre slip.

Beta Design Consultants design will avoid the use of multiple layers of mesh and will limit the bond stress to values that can practically be achieved and tested on site and witnessed by our engineers.

3. UHM CFRP (Ultra High Modulus Carbon Fibre Reinforced Polymers)

BACKGROUND ON UHM CFRP Strengthening

Ultra-High Modulus (UHM) carbon fiber reinforced polymer (CFRP) offers even greater strength and stiffness compared to conventional CFRP materials. When used to strengthen metallic structures, such as cast iron beams, cast iron bridges, jack arch bridges, UHM CFRP brings several advantages:

-

Enhanced Strength and Stiffness: UHM CFRP boasts exceptional mechanical properties, including high tensile strength and stiffness. When bonded to metallic structures, it significantly reinforces them against external loads and improves their load-carrying capacity.

-

Reduced Weight: Despite its exceptional strength, UHM CFRP is lightweight. By incorporating UHM CFRP into metallic structures, you can achieve significant weight savings while maintaining or even enhancing structural integrity. This is particularly valuable in applications where weight reduction is critical, such as aerospace and automotive industries.

-

Improved Fatigue Resistance: UHM CFRP's high stiffness helps distribute stresses more evenly throughout the structure, reducing the risk of fatigue failure. This is especially beneficial for metallic structures subjected to cyclic loading, as UHM CFRP can effectively mitigate fatigue damage and extend the service life of the components.

-

Tailored Reinforcement: UHM CFRP can be customized to match the specific requirements of the metallic structure, including shape, thickness, and orientation of the fibers. This allows engineers to tailor the reinforcement to address specific stress concentrations or weak points within the structure, maximizing performance and efficiency.

-

Corrosion Resistance: Like conventional CFRP, UHM CFRP provides excellent corrosion resistance. By encapsulating metallic structures with UHM CFRP layers, you can protect them from environmental factors that could lead to corrosion, extending their lifespan and reducing maintenance costs.

-

Ease of Installation: UHM CFRP can be easily applied to metallic structures using various bonding techniques, such as adhesive bonding or mechanical fastening. Its flexibility allows it to conform to complex geometries, ensuring a secure and efficient installation process with minimal disruption to operations.

-

Temperature Resistance: UHM CFRP exhibits good temperature resistance, making it suitable for use in high-temperature environments where conventional materials may degrade or lose strength. This expands the range of applications where UHM CFRP can be effectively employed for strengthening metallic structures.

Our team has used UHM CFRP as they offer a compelling solution for strengthening metallic structures that have aged (e.g. London Heritage stock of bridges contains many cast iron beams and jack arch bridges, the same applies to Network Rail and local authorities stock of bridges). This material has allowed our team to provide exceptional strength, stiffness, and durability while offering benefits such as weight reduction, fatigue resistance, and corrosion protection. UHM CFRP versatility and superior performance make it a valuable tool for Beta clients seeking to enhance the performance and longevity of metallic structures across various industries.