CFRP and HPC Concrete Strengthening for Brindleyplace

Beta Scope

Beta Design Consultants provided the specialist RC Strengthening design. We worked with the specialist strengthening contractor Restek, with Willmott Dixon’s Construction Management Team and with the Client’s Structural Engineer Cundall’s to develop the strengthening strategy that meets technical, budget and programme requirements.

At the tender stage:

- Our engineers took part in Early Contractor Involvement meetings with the client. We visited the site Restek and identified constraints relating to logistics, access, programme and budget.

- Our engineers evaluated the forces, beams existing capacity and proposed a solution for each case based on FRP use where possible and HPC use where FRP use was not technically feasible.

- Our engineers worked with Restek to obtain an idea about bond capacity for existing concrete by arranging some pull-out testing.

- We produced an initial material take off that allowed Restek to offer the client an all-risks tender with certainty of cost and programme.

At the design stage:

- We worked with Cundall’s to identify the governing design conditions for the beams. Some assumptions were made at the tender stage and these needed to be refined to ensure strengthening proposals reflected accurate calculations stripping out any conservative assumptions. Examples include taking into account the real split of dead and live loads in each level as the feasibility for FRP strengthened members is governed by ability of beams to withstand proposed permanent loads.

- We favoured the use of FRP where possible. Where this was not possible, we considered strengthening the beams with HPC on top to enable FRP to be used (as this would increase moment capacity of beams allowing FRP to be viable).

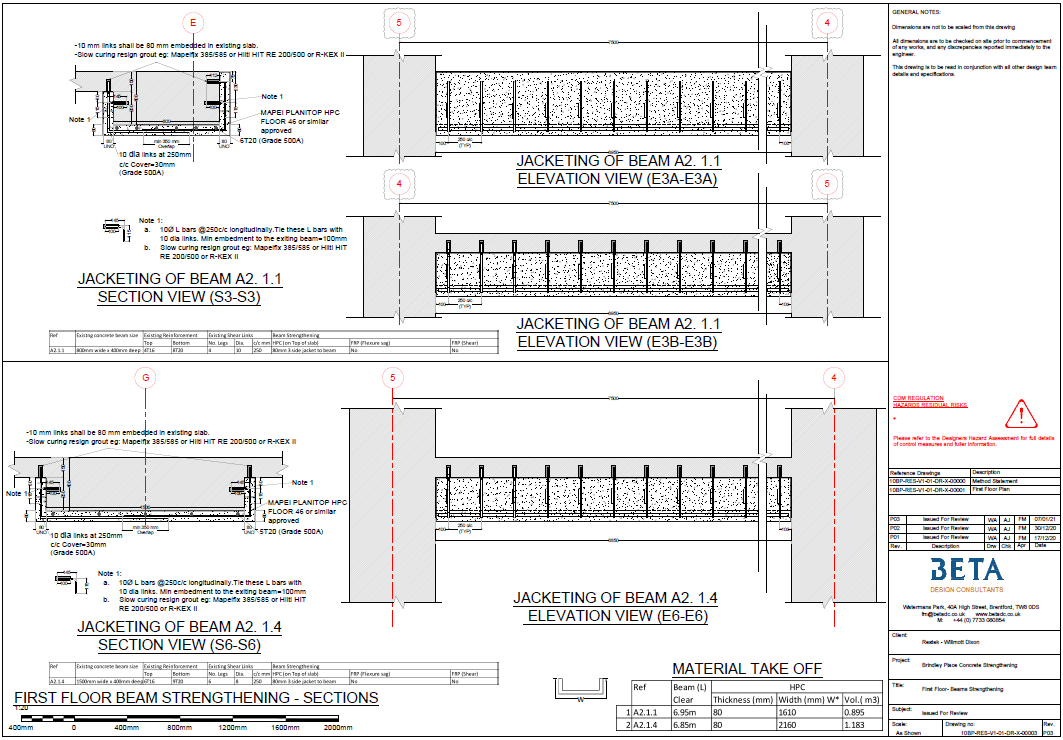

- Where FRP was not feasible at all, we proposed use of 3-sided jackets made of HPC. This was linked to existing beams and slabs using carefully designed shear connectors.

- Shear strengthening was designed using FRP wraps.

- We produced a detailed material take off to allow the contractor and the client to plan works and evaluate impact on other trades (e.g. steelwork installation).

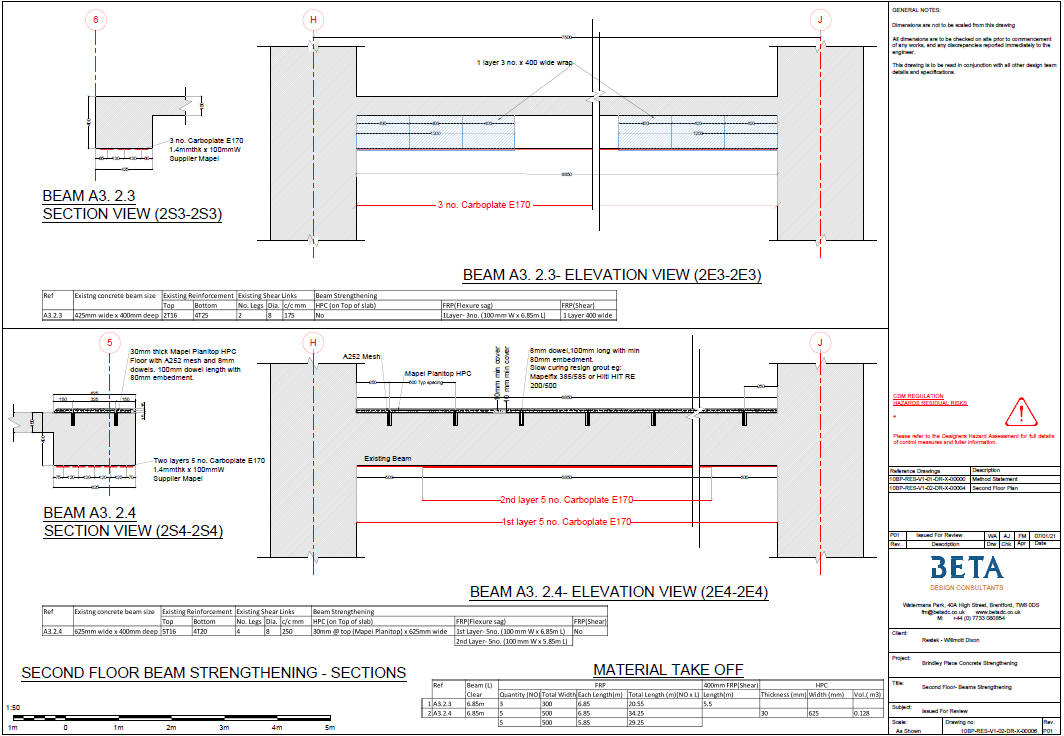

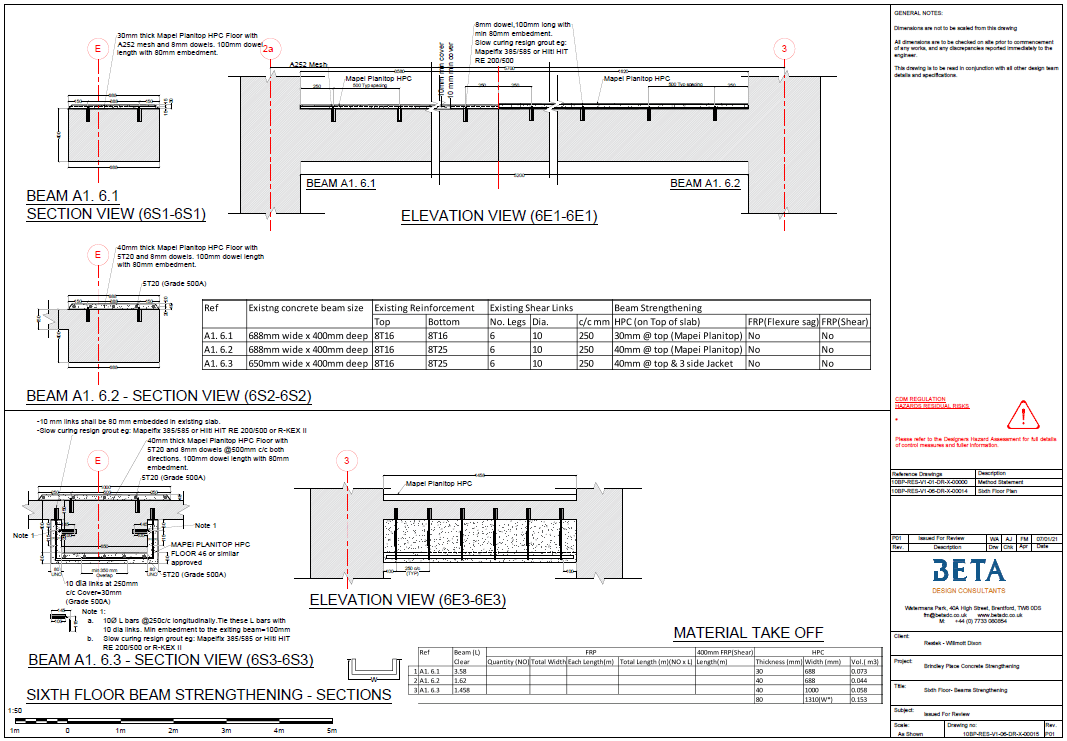

- – 24 No Beam Strengthening for flexure sagging only using (Fibre Reinforced Polymer) FRP.

- – 26 No Beam Strengthening for flexure sagging only using FRP after adding HPC on top.

- – 6 No Beam Strengthening for flexure sagging only using 3 side Jacket of High Flow Grout.

- – 5 No Beam Strengthening for flexure hogging only using (High Performance Concrete) HPC.

- – 7 No Beam strengthening for shear using FRP shear U wrap.

At the execution stage:

- We worked with Cundall’s to resolve clashes.

- We engaged in meetings with the project team and identified 12 cases where jacketing could cause programme delays. We advised that strengthening could be redesigned to take into account higher values of bond if testing justified these values. We recommended testing and advised the client of locations and scope of testing.

- We revisited the design of the 12 beams replacing 6 of the previously designed jackets with FRP adopting the bond values that the testing justified.

- For the 6 cases of 3-side jacket, we specified flowable concrete to support ease of installation.

Background

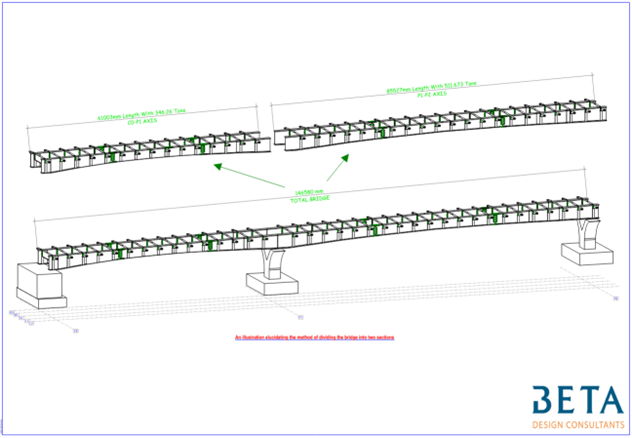

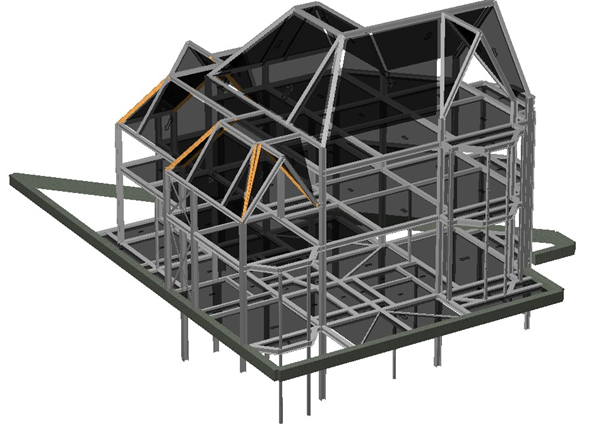

Willmott Dixon are selected by the client, CBRE Global Investors, to undertake the complete transformation of 10 Brindleyplace to modern CAT-A standards. The vision of the client, designed by Associated Architects, is to combine 10 and 8 Brindleyplace into one building to create 212,000 square foot of open office space over nine floors, providing one of Birmingham’s largest available floorplates at over 27,000 square foot.

The works include creating an internal reconfiguration, with the construction of a brand new double height reception space and the creation of a new entrance. New infill slabs were added with additional loading on the existing frame. This required the flexural and shear strengthening of 61 beams at various levels.

Technical Details

The strengthening method suitable for a particular beam depends on the existing beam capacity in moment and shear and the future design moment and shear. The preference was to strengthen using FRP as this approach would less preparation, minimum resin setting time, and no shuttering which would result in supporting the program. However, FRP strengthening has limitations as the existing beam needs to satisfy serviceability limit state loading as per TR 55 clause 6.2.2. This condition requires that the strain of the strengthened beam be within set limits and that the strengthened beam be capable of resisting future permanent loads (ability to sustain frequent load combination without FRP). If these conditions were not satisfied, we proposed adding HPC on top of existing section to increase existing beam ultimate resistance capacity and then add FRP to strengthen the beam. If this also did not work, or if FRP would fail in de-bonding, we proposed strengthening with 3 side HPC Jacket. The 3 side HPC jacket was the last option as it would require more setting time, shuttering and access requirement, so it was applicable only when all other strengthening methods were not possible.

Thus in general for strengthening design the following steps were followed:

- Step-1

- The in-house developed design sheet is used to calculate moment of resistance of existing T-beam and check against maximum design bending moment in SLS -Frequent load combination to satisfy condition for FRP use. If the condition is not satisfied, then the T-beam is checked using HPC. The sections is reinforced with required HPC thickness on top of existing slab to increase moment of resistance of existing T- beam such that the modified moment of resistance of T-beam is more than maximum design bending moment in SLS -Frequent load combination.

- Step-2

- Check existing beam required flexural strengthening to establish size of FRP.

- Step-3

- Check existing beam required shear strengthening to establish if any FRP wraps are required.

- Step-4

- Design FRP size for flexural and shear checks as specified in TR 55.

- Step-5

- If FRP is not viable, design the HPC jacket required to carry the load (using 3 sided jackets or as required).

Materials Used

We worked very closely with material supplier Mapei. This cooperation resulted in the following:

- Correct choice of materials

- Practical method statement

- Realistic lead time

This cooperation supported the project overall and ensured that any issue was addressed without any lost time.

The project used the following materials:

- Flexural Strengthening with FRP: Mapei Carboplate E170 FRP

- Shear Strengthening with FRP: Mapei Mapewrap FRP

- Flexural and Shear Jacketing: Mapei High Performance Concrete Planitop HPC (above beams) and Mapei Grout Hi-Flow for Jacketing.

Acknowledgements

Beta Design Consultants would like to acknowledge professional support from:

- – Simone Timone from Mapei whose input was crucial to solving many of the challenges we faced. It was Simone’s idea to carry out pull-out testing to the beams to justify the use of higher bond strength values enabling more beams to be strengthened using FRP.

- – Dr Spyridon A. Paschalis from the University of Bolton, whose PHD research at the University of Brighton guided us. The recommendations in the PHD Research confirmed our judgement to use reinforcement and shear connectors when specifying the top and the 3-side HPC jackets.

https://cris.brighton.ac.uk/ws/portalfiles/portal/4756258/Spyridon_Paschalis_P

References

The concrete repair design methods are based on the following technical guide and reports:

- Technical Report No. 55: Design guidance for strengthening concrete structures using fibre composite materials.

- Technical Report No. 57: Strengthening concrete structures using fibre composite materials: acceptance, inspection, and monitoring.

- Technical report No. 69: Repair of concrete structures with reference to BS EN 1504.

- Concrete Repair to EN 1504: Diagnosis, Design, Principles, and practice: By Michael Raupach Till Buttner.

- The Institution of Structural Engineers Appraisal of Existing Structures (third edition).

- IABSE Structural Engineering Documents: Case Studies of Rehabilitation, Repair and Strengthening of Structures.

.png)