Pembroke Road Footbridge - Principal Inspection, Structural Investigation & Strengthening

Background

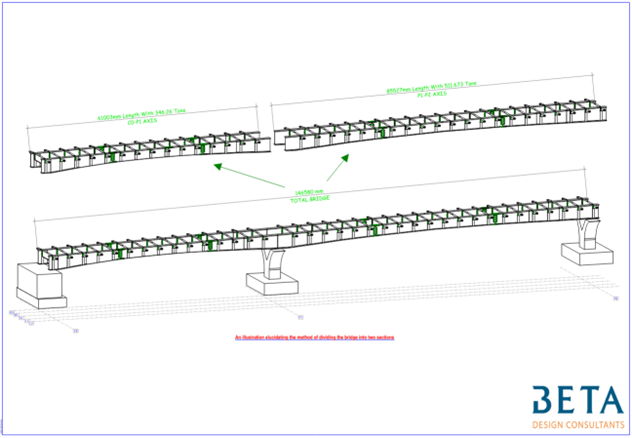

At Beta Design Consultants, we are committed to delivering innovative and practical structural solutions that extend the life and safety of vital infrastructure. Our recent project at Pembroke Road Linkbridge involved the Principal Inspection of the Link Bridge, the Special Inspection of the Steel Footbridge and the refurbishment design of a the double-deck steel truss footbridge that required essential structural maintenance and an external steelwork coating.

The aim of this project was to ensure the footbridge remained safe, durable, and compliant with modern standards while improving its aesthetic appeal. The client had closed the bridge, declared it unsafe for use and installed temporary props. This case study highlights our approach to reinstate the footbridge, showcasing our thorough planning, execution, and quality assurance.

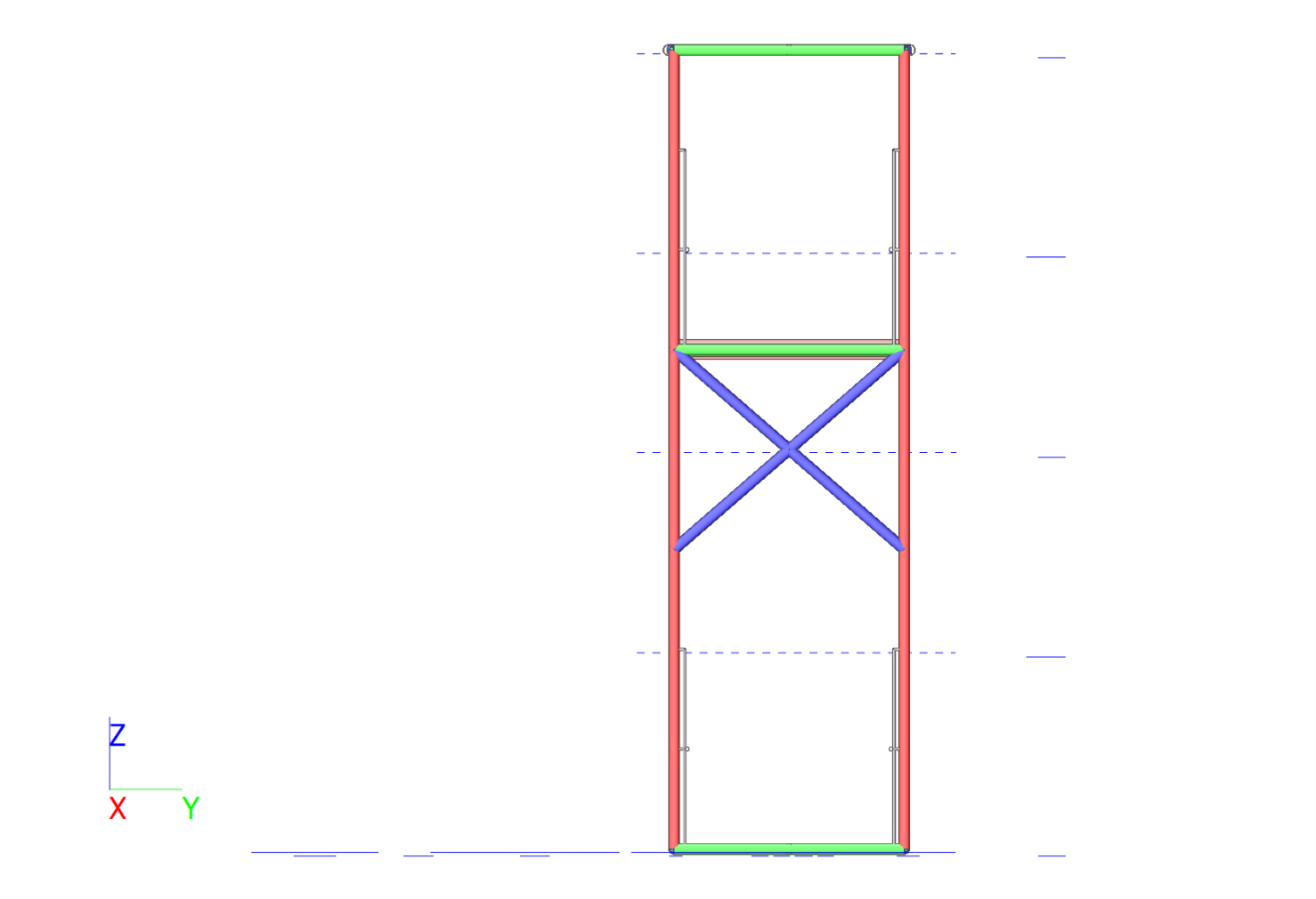

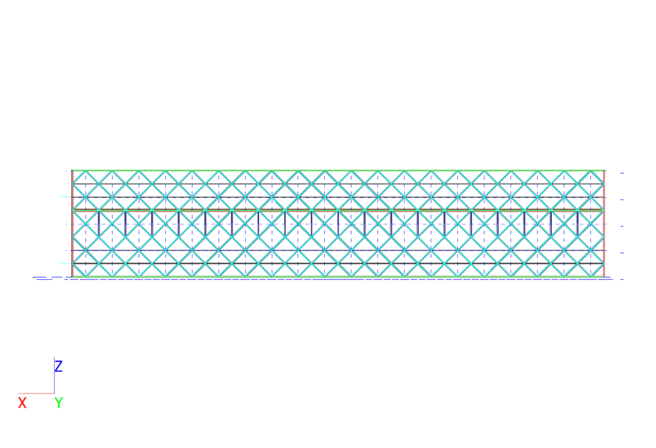

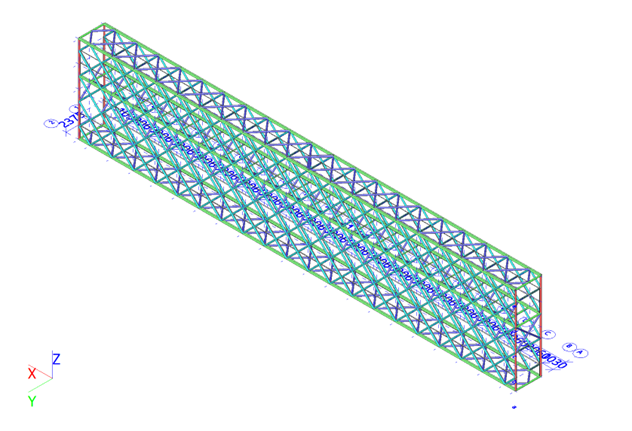

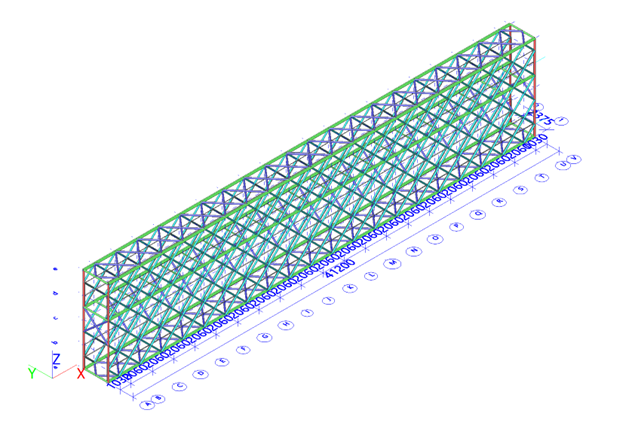

The steel truss footbridge serves as a key pedestrian connection between two residential developments. Over the years, the structure has shown signs of corrosion, wear, and damage exacerbated by a failing waterproof system and a non-existent surface drainage system. The footbridge steel truss decks were exposed to the elements. With a height of 8.5 meters and a span of 42 meters, the footbridge was no longer meeting safety standards, posing a risk to users and requiring intervention.

The project involved a comprehensive investigation of the steelwork, followed by detailed structural assessment and the proposals for bearings inspection and reinstatement of protective coatings. The goal was to ensure that the structure could continue to serve for the next 25+ years.

Scope of Work

- Principal Inspection of the Bridge (within touching hands distance).

- Structural Investigation

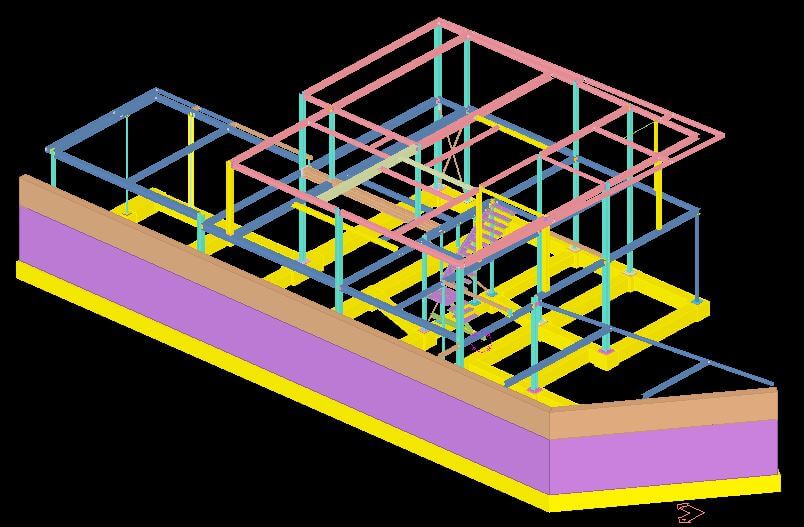

Our team conducted a detailed visual inspection and ultrasonic testing of the steel structure. Key findings included:

- Corrosion: Minor to severe corrosion in certain areas, especially at the supports and joints.

- Bolting Issues: Some bolts had loosened or showed signs of corrosion, threatening the integrity of the connections.

- Surface Damage: The existing coating system was inadequate, with areas of flaking and wear.

Using advanced testing methods, including ultrasonic thickness testing (UTT), we assessed the remaining material thickness of the CHS truss members. The results guided the design of the refurbishment and strengthening measures.

- Design of Refurbishment and Strengthening Measures

To restore the footbridge to its original capacity and extend its service life, we proposed a comprehensive refurbishment plan, including:

- Bolt Replacement and Maintenance: Tightening and replacing corroded bolts with corrosion-resistant, high-quality locking bolts to ensure the structural integrity of the connections.

- Surface Preparation and Coating Application: The steel structure was cleaned using jet washing and abrasive blasting to meet ISO 8501-1 SA2½ standards. This was followed by a multi-layer coating system to protect the steel from further corrosion and extend the life of the structure.

- Epoxy Primer: Applied at a dry film thickness (DFT) of 100 µm.

- Fire Protection Coating: Applied in two coats to all welds and connections for added safety.

- Polyurethane Topcoat: Applied at a DFT of 50 µm to provide a durable and weather-resistant finish.

- Structural Analysis and Safety Compliance

Detailed structural analysis was performed to ensure the footbridge could accommodate current and future loads, including pedestrian traffic and environmental conditions. Our design complied with the relevant safety standards, ensuring the refurbishment would meet both short-term compliance and long-term durability.

BDC’s approach focused on providing practical, cost-effective solutions that ensure the continued functionality of the facility while minimizing disruptions to service operations and residents.

Challenges and Solutions

Throughout the project, Beta Design Consultants overcame several challenges to ensure the successful delivery of the design:

- Access and Safety

The footbridge was located in a public area, requiring careful planning for scaffolding and worksite setup to minimize disruption. We ensured that all work at height was carried out safely using appropriate scaffolding, PPE, and safety measures to protect workers and pedestrians.

Solution:

We provided a robust scaffolding system designed for safe access to all areas of the steelwork, and implemented traffic management plans to protect the public.

- Durability of Coating System

The steel structure was exposed to harsh weather conditions, which had led to accelerated deterioration of the existing coating system.

Solution:

We specified a high-performance multi-coat system that provided long-term protection against rust, wear, and environmental exposure, ensuring a durable finish and extended service life.

- Minimizing Disruption

Given the structure’s location in a high-traffic area, minimizing disruption was a key concern.

Solution:

We developed a phased approach to the work, allowing for minimal downtime. Temporary barriers and signage were set up to ensure safety and minimize the impact on footbridge users.

Experience

Beta Design Consultants has a strong track record of successfully managing and delivering complex structural engineering projects, particularly in the public sector. Our expertise in assessing building conditions, proposing practical solutions, and delivering cost-effective refurbishments makes us a trusted partner for projects of this nature.