Stanmore House Strengthening

Beta Scope

- Structural analysis of existing RC Frame

- Design of concrete structural strengthening using FRP and HPC

- Temporary works design for support of frame during column and walls removal

- Construction method statement for ground beam strengthening, steel installation and RC column removal

- Site supervision of concrete repairs

Background

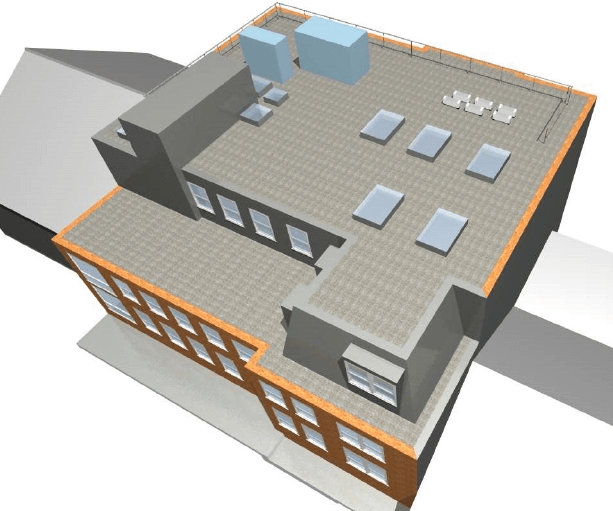

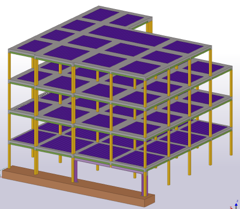

Beta Design Consultants were commissioned by Jaspar Group to prepare the structural design for the removal of an RC column at the ground floor of Stanmore House, a four-storey mixed-use building in Harrow, London. The brief was to propose a solution without infringing on the headroom. The contractor was appointed and needed to advise on the installation cost so a concept design was required within a week from our appointment. The building includes residential flats owned by third parties at the top two levels so it was imperative that deflections be kept as low as possible.

Beta Solution

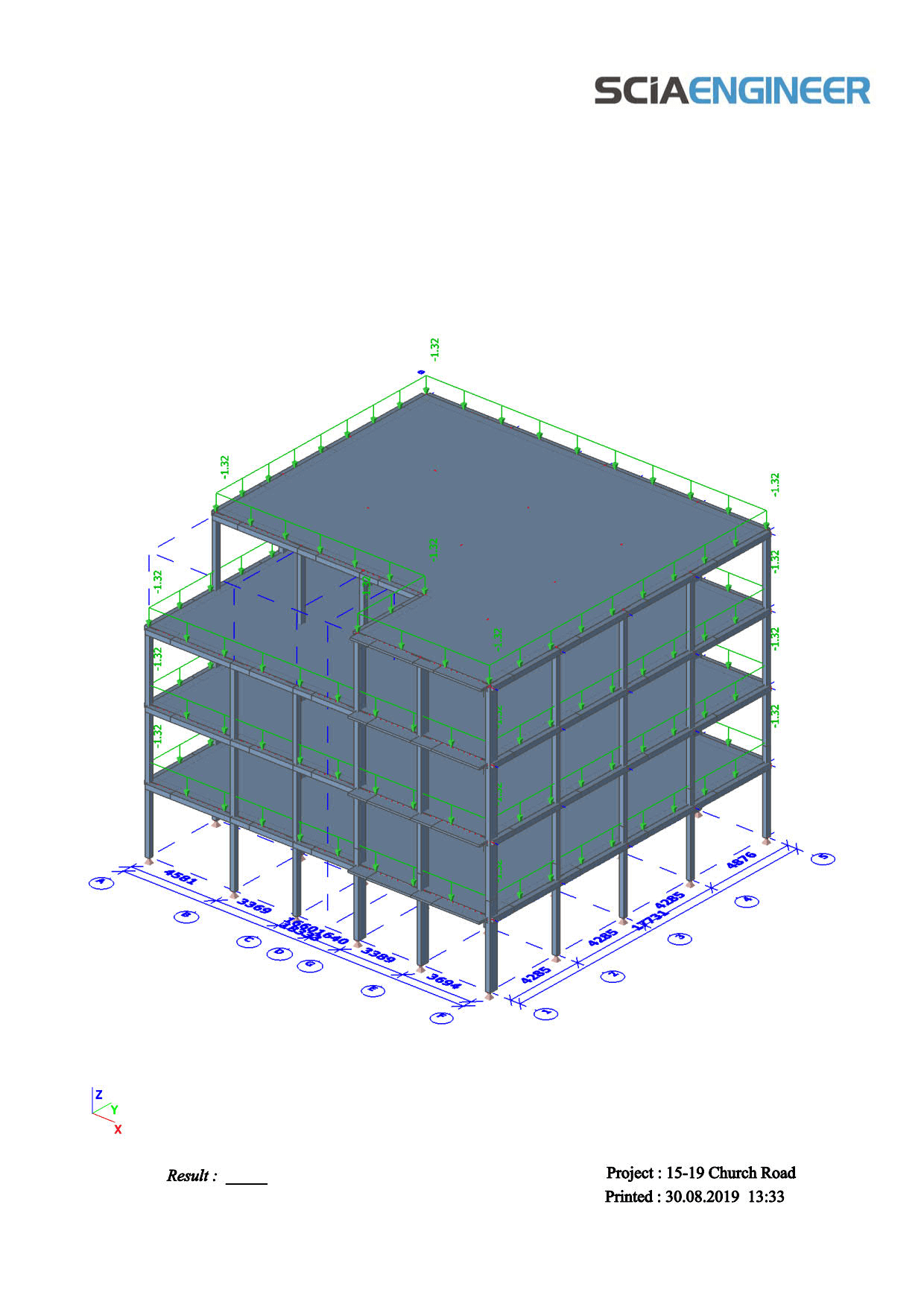

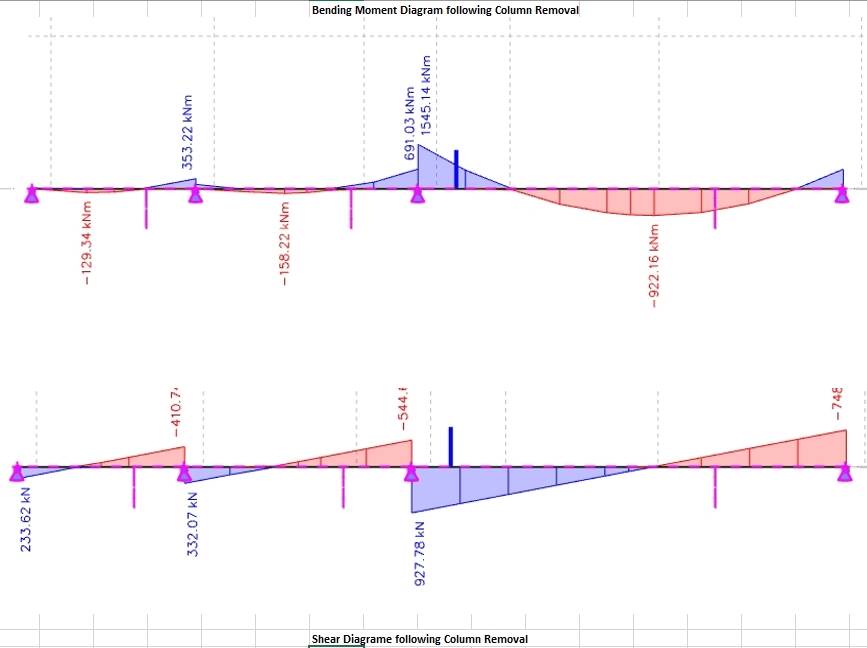

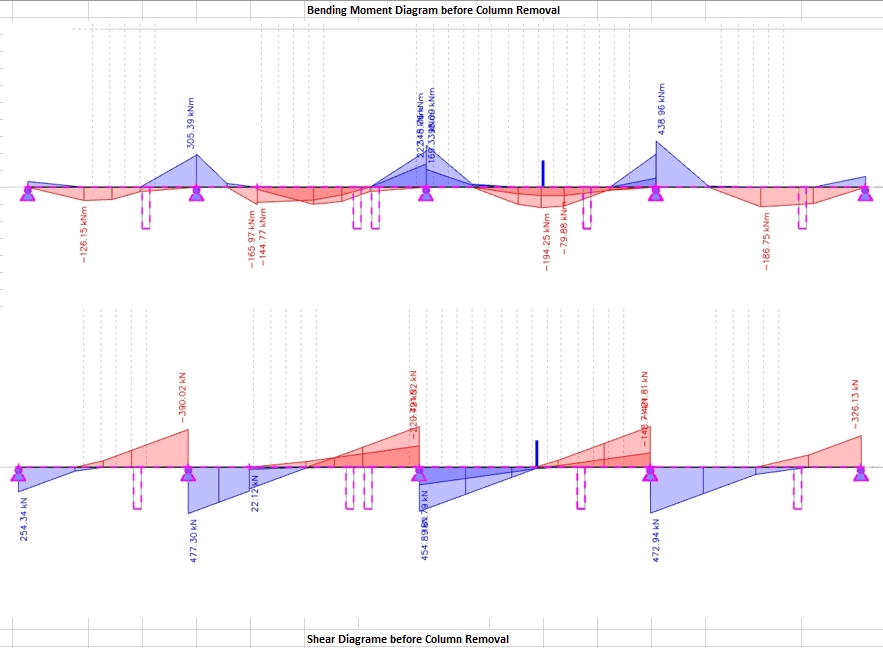

Beta Structural Engineers established existing loading on the column using SCiA Engineer. They established the size of the steel frame required to support the RC building following the column removal. They also established the existing ground beam capacity and it was clear that the ground beam would not have been designed to support the loading of the revised scheme. The ground beam was designed to be supported on columns at even spacing and by removing the column, the ground beam was spanning twice the distance, leading to a large negative moment and shear force at the other remaining supports. Beta Design Consultants looked into using FRP plates for bending strengthening, and GFRP bars for shear strengthening but these did not offer the required capacity. In the end a mix of FRP and HPC was established as the best way forward.

Practical Details

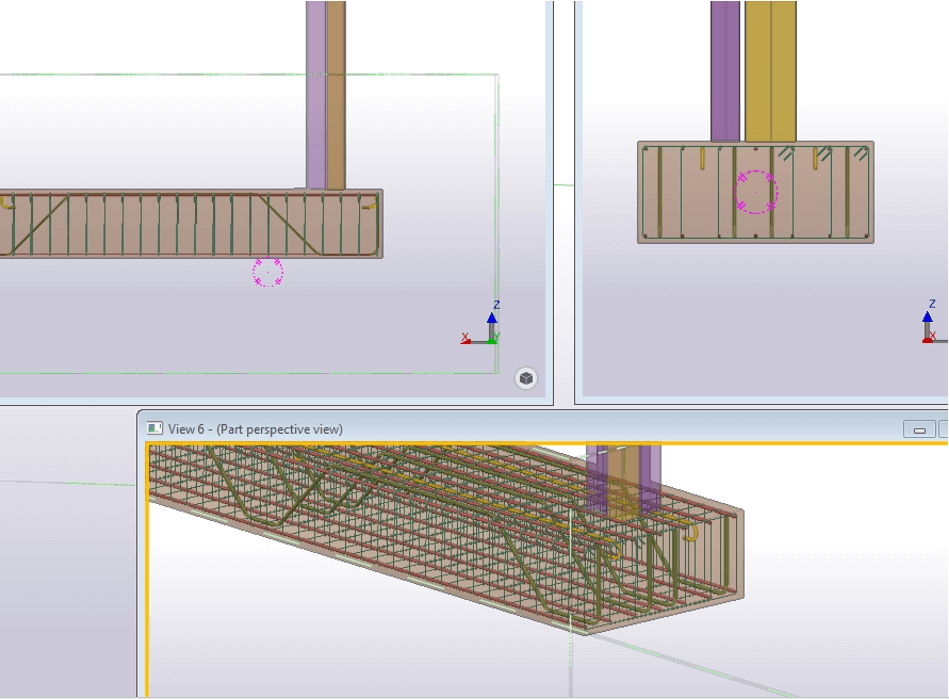

Tekla Structures was used to model the existing ground beam and the intended locations of the bars.

Beta Structural Engineers worked with Mapei Design Team to finalize the design and confirm the exact products to be used and their lead time. A suitable installer was appointed to match the compressed programme.

Having completed the design, Jaspar Group and their Principal Contractor, asked Beta Design Consultants to prepare the temporary works design and propose the construction method statement. Mabey Props Mass 50 were used in conjunction with a system of needling to support the external wall during the erection of steel.