Kennedy Institute Extension - Flat Slab Punching Shear Strengthening

Link: Visit project

Beta Scope

- Evaluation of flat slab punching shear repair options including FRP, Hilti Post Installed Studs and traditional post installed shear anchors

- Recommending the most practical option for punching shear repair considering the programme

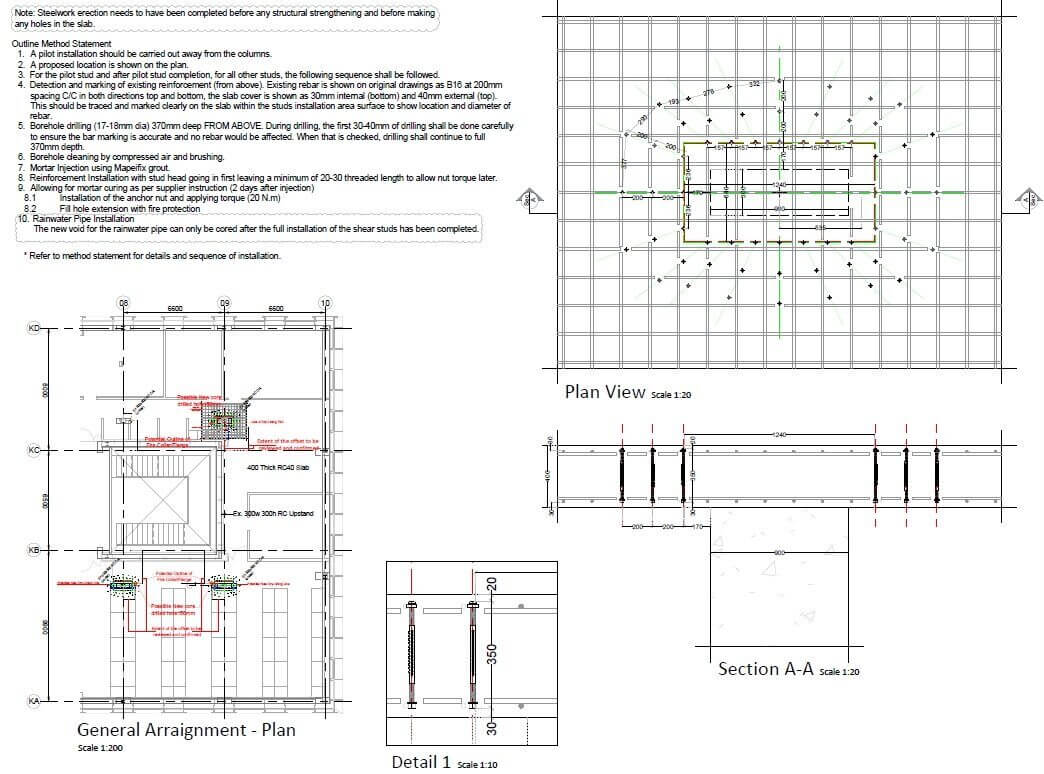

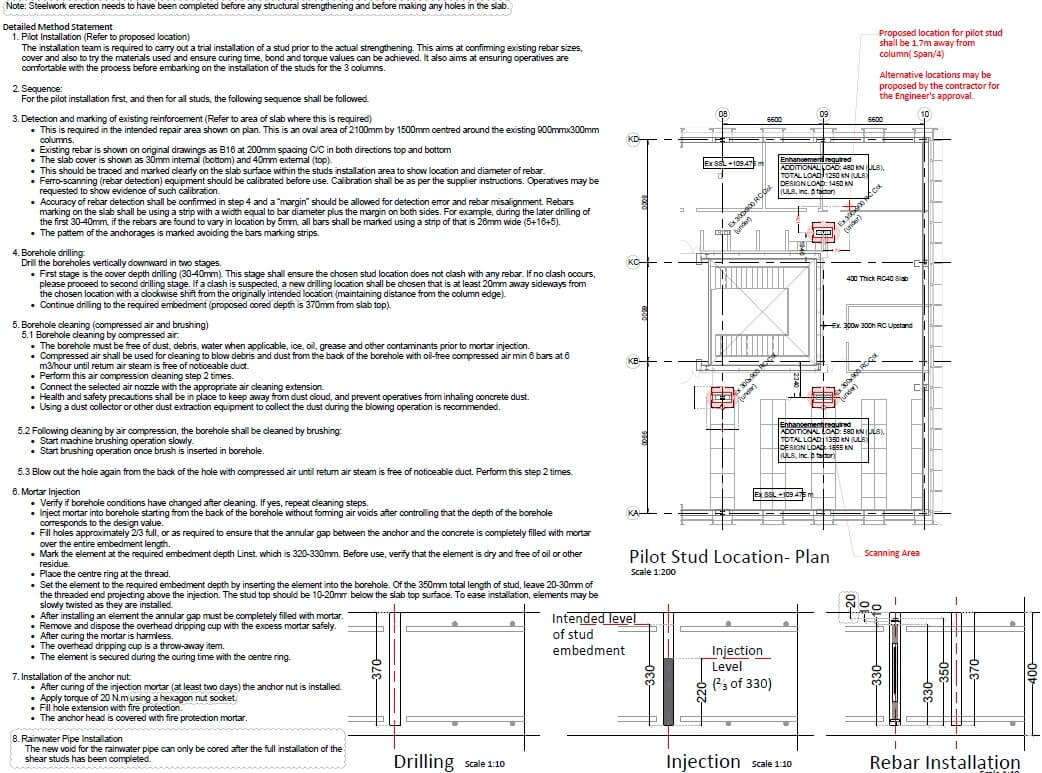

- Designing the required post installed studs, suitable diameter and spacing

- Construction method statement including specifications of grout and torque method

Background

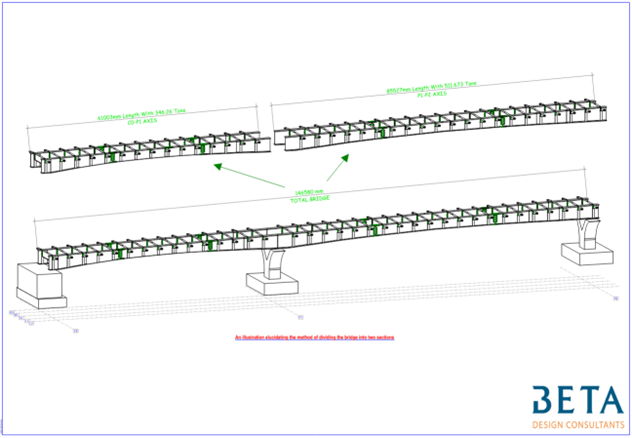

Beta Design Consultants were commissioned by the Principal Contractor, Beard Construction, to provide the specialist repair design to address punching shear failure in the flat slab. The project was the addition of a new storey for the Kennedy Institute of Rheumatology. When checking the existing building, the Engineering consultant for the University of Oxford (AKS Ward) identified an issue in the punching shear of the flat slab. Beta Design Consultants were appointed to evaluate various options for the repair and to recommend a suitable solution. The institute was to remain operational without any disruption and all repair works had to be carried out from above.

Beta Solution

Beta DC Engineers evaluated the available options and the following options were considered:

- Using fibre reinforced polymer FRP plates or rods was seen as an ideal solution. However, this was dismissed as the grid of required FRP clashed with the positions of steel columns that needed to be added.

- Using the post installed Hilti anchors was also considered. This was later eliminated due to the need for access from below the slab.

- Beta DC Engineers proposed a method that they had previously used. The method is derived from basic engineering principles and is based on working out the required shear reinforcement and then post installing it. This method allowed the columns installation for the new storey to proceed and it required access from above only.

Practical Details

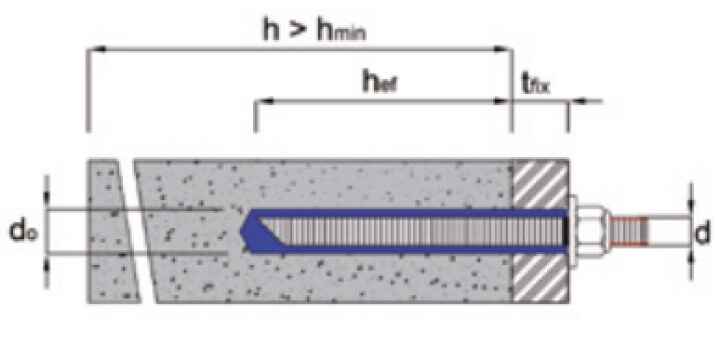

Beta Design Consultants solution was to drill the slab and install specially designed studs, with a domehead and a nut washer assembly. These studs were installed vertically from above in special grout. Following grout curing, the studs were torqued. The studs were checked for steel resistance, bond strength and pull-out strength and a sufficient number of studs were used to counteract the shear force that exceeded the concrete shear strength without reinforcement.

Few concerns had to be addressed on site and these included:

- Risk of hitting existing rebar

- Risk of overheating in the grout due to the relatively large volume of grout used.

- Risk of piercing through the slab and disturbing the operational health facility.

Beta Design Consultants worked with Beard Construction to prepare a method statement that addressed all these risks. A ferro scan was carried out to ensure position of rebar was established prior to specifying studs locations. A trial stud installation was carried out and witnessed by Beta DC Engineers. The installation sequence allowed for the measurement of existing slab thickness prior to drilling to avoid piercing through the slab. The repair was carried out successfully by specialist concrete repair contractor CRL LTD allowing the programme to progress.

Client: University of Oxford

Architect: Make Architects

Location: Kennedy Institute

Related projects

St Peter’s Hospital Staff Accommodation, Piled Rafts Design

Read More

RAAC Investigation and Structural Strengthening

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

Action Court Warehouse Extension

Read More

Engine Yard Punching Shear Slab Strengthening

Read More

CPS House Jacketing to Strengthen RC Beams

Read More

BP Deep Water Sump Assessment and Concrete Repair Design

Read More

BP Heater Foundation Concrete Repair

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

BP GF Gas Plant – Slug Catcher Foundation Walls RC Repair

Read More

Fulham Palace Road Temporary Works Design

Read More

Harwell Campus-Concrete Strengthening

Read MoreLondon Hippodrome Roof Extension – Structural Design and Detailing

Read More

Structural Repairs of a Listed Building

Read More

Orchard House – RC Column Strengthening using CFRP

Read More

Stanmore House Strengthening

Read More

Bus Depot Electrification Harrow

Read More

Nant Melyn Bridge Inspection for Assessment

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More

Structural Assessment of Henley Masonry Arch Bridge

Read More

Northside Garages Structural Investigation

Read More

Peckham Arch Condition Survey & Life Extension Consulting Services

Read More

Pembroke Road Footbridge - Structural Investigation & Strengthening

Read More

Concept Design of Sedhiou Bridge and Roads Network

Read More

Helmsley Place-Steel Connections Design and Detailing

Read More

CFRP and HPC Concrete Strengthening for Brindleyplace

Read More

Planning Permission for 21 Boston Road Townhouse Conversion

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

Planning Application for Three Story Residential Building

Read More

Value Engineering for Warehouse and Office Building

Read More

Planning Permission for New Warehouse, Ealing

Read More

Three Story Warehouse Steel Structure Design

Read More

Planning Permission for a Basement in a Conservation Area

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

One West Point – Design of Support System for Cladding

Read More

Structural Design of 3 Storey Building

Read More

Queens Rise- Steel Structure Connection Design and Detailing

Read More

Grove Park Gardens 4 Storey Residential Development

Read More

LABSA Sulphonation Plant Erbil

Read More