Engine Yard Punching Shear Slab Strengthening

Beta Scope

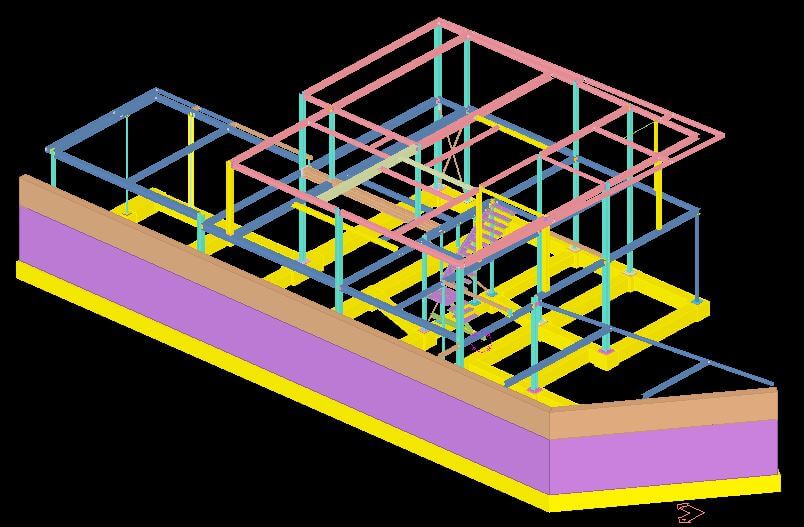

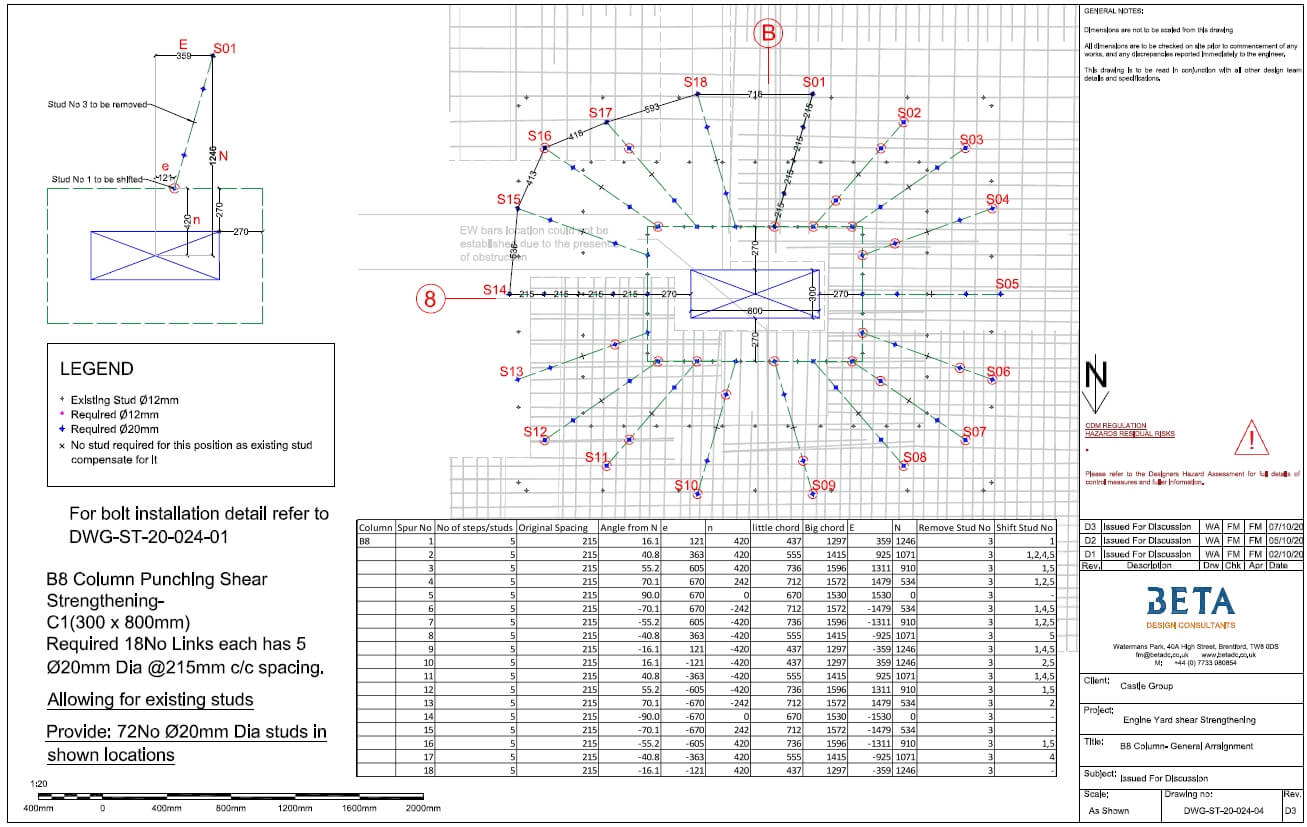

- Stab Strengthening design using nearly 900 anchors using Model Code 2010.

- Verifying reactions and slab shear capacity.

- Evaluating options such as column capitals, FRP, slab thickening and post installed anchors.

- Evaluating options for post installed anchors.

- Preparing method statement.

- Preparing specification for testing.

Background

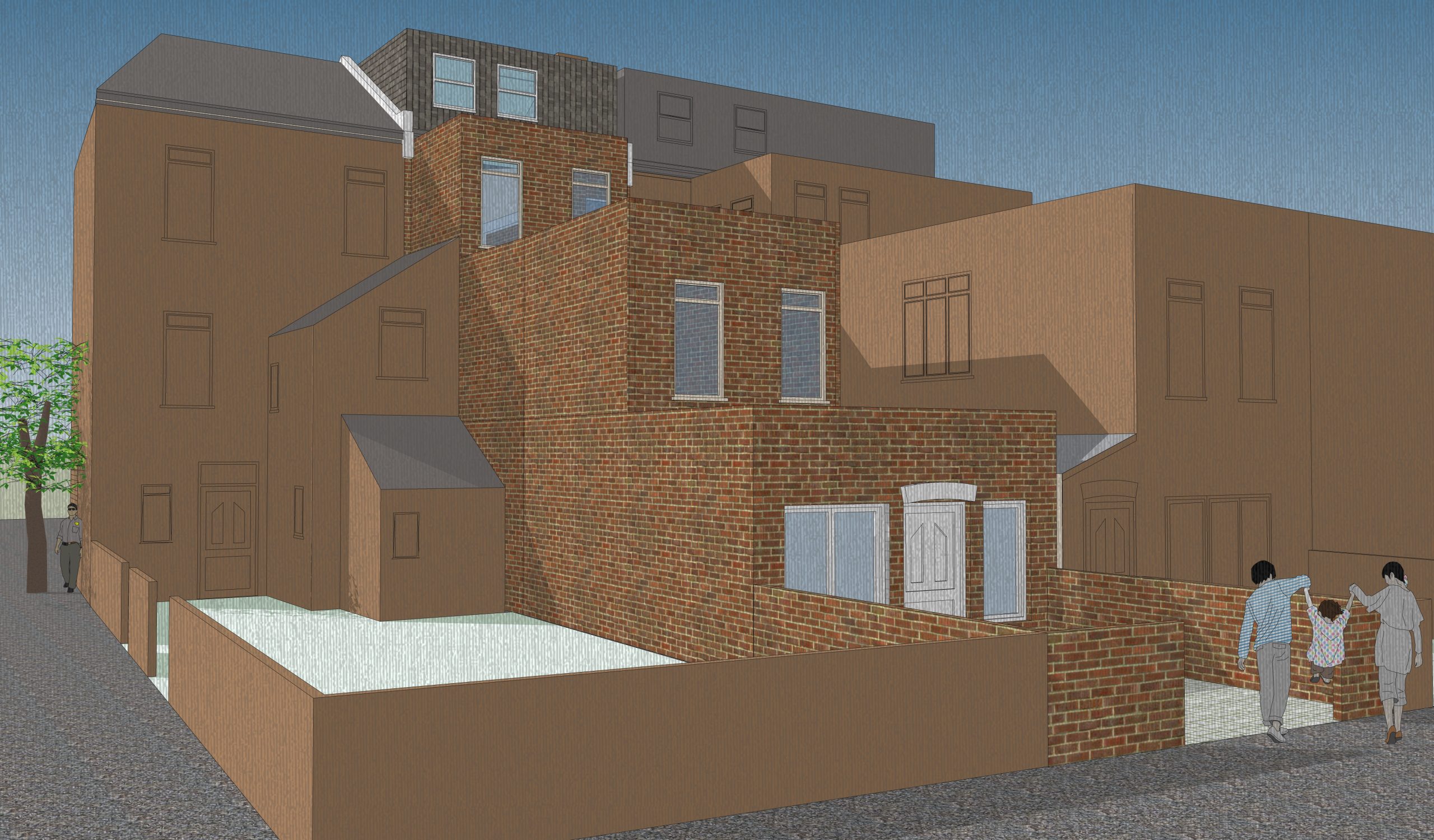

Beta Design Consultants were commissioned to provide the specialist repair design to provide punching shear slab strengthening. The transfer flat slab was found to require punching shear strengthening following project completion. Beta Design Consultants were appointed to evaluate various options for the repair and to recommend a suitable solution. All repair works had to be carried out from below.

Beta Solution

Beta DC Engineers evaluated the available options and the following options were considered:

- Using fibre reinforced polymer FRP plates or rods was seen as an ideal solution. However, this was dismissed as the grid of required FRP clashed with the positions of the existing columns .

- Using the post installed Hilti anchors was also considered. This was later eliminated due to the need for access from below the slab only. The Hilti method requires access from below and above.

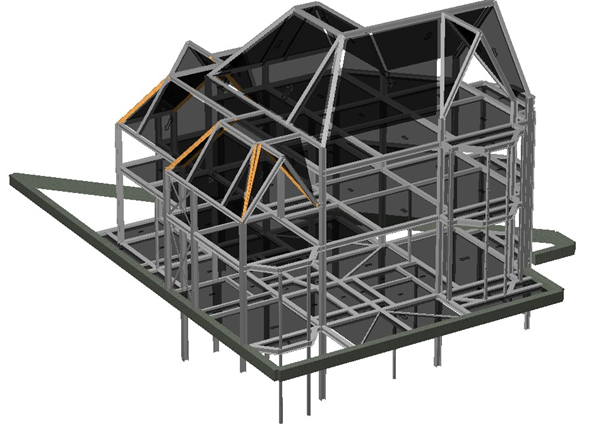

- Beta DC Engineers proposed a method that they had previously used. The method is derived from basic engineering principles and is based on working out the required shear reinforcement and then post installing it. This method required access from below only for the slab strengthening.

Practical Details

Beta Design Consultants solution was to drill the slab and install specially designed studs, with a domehead and a nut washer assembly. These studs were installed vertically from below in special grout. Following grout curing, the studs were torqued. The studs were checked for steel resistance, bond strength and pull-out strength and a sufficient number of studs were used to counteract the shear force that exceeded the concrete shear strength without reinforcement.

Few concerns had to be addressed on site and these included:

- Risk of hitting existing rebar

- Risk of overheating in the grout due to the relatively large volume of grout used.

- Risk of piercing through the slab and disturbing the function of the building above the slab.

Beta Design Consultants worked with Castle Group Engineers to prepare a method statement that addressed all these risks. A ferro scan was carried out to ensure position of rebar was established prior to specifying studs locations. A trial stud installation was carried and findings reviewed by BDC Engineers. The installation sequence allowed for the measurement of existing slab thickness prior to drilling to avoid piercing through the slab. The repair was carried out successfully by specialist concrete repair contractor Castle Group.

Quality Control and Inspections

BDC scope included a review of QC records and the specification and review of the testing.

The specified concrete repair /slab strengthening was designed according to EN1504 and two tests were specified by Beta Design Consultants and arranged by Castle Group:

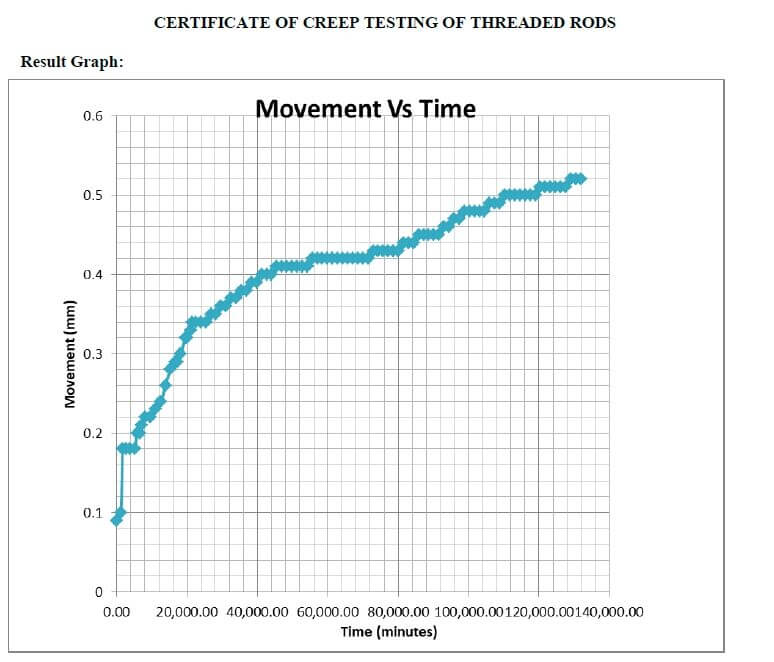

- Pull out testing to 75 kN. This ensured displacement does not exceed 0.6mm at a load of 75 kN.

- Creep test for 3 months at 50 kN. This ensured displacement does not exceed 0.6mm at a sustained continuous load of 50 kN for 3 months.

Both tests were successfully completed.