St Peter’s Hospital Staff Accommodation, Piled Rafts Design

Beta Scope

Beta Design Consultants comprised the following:

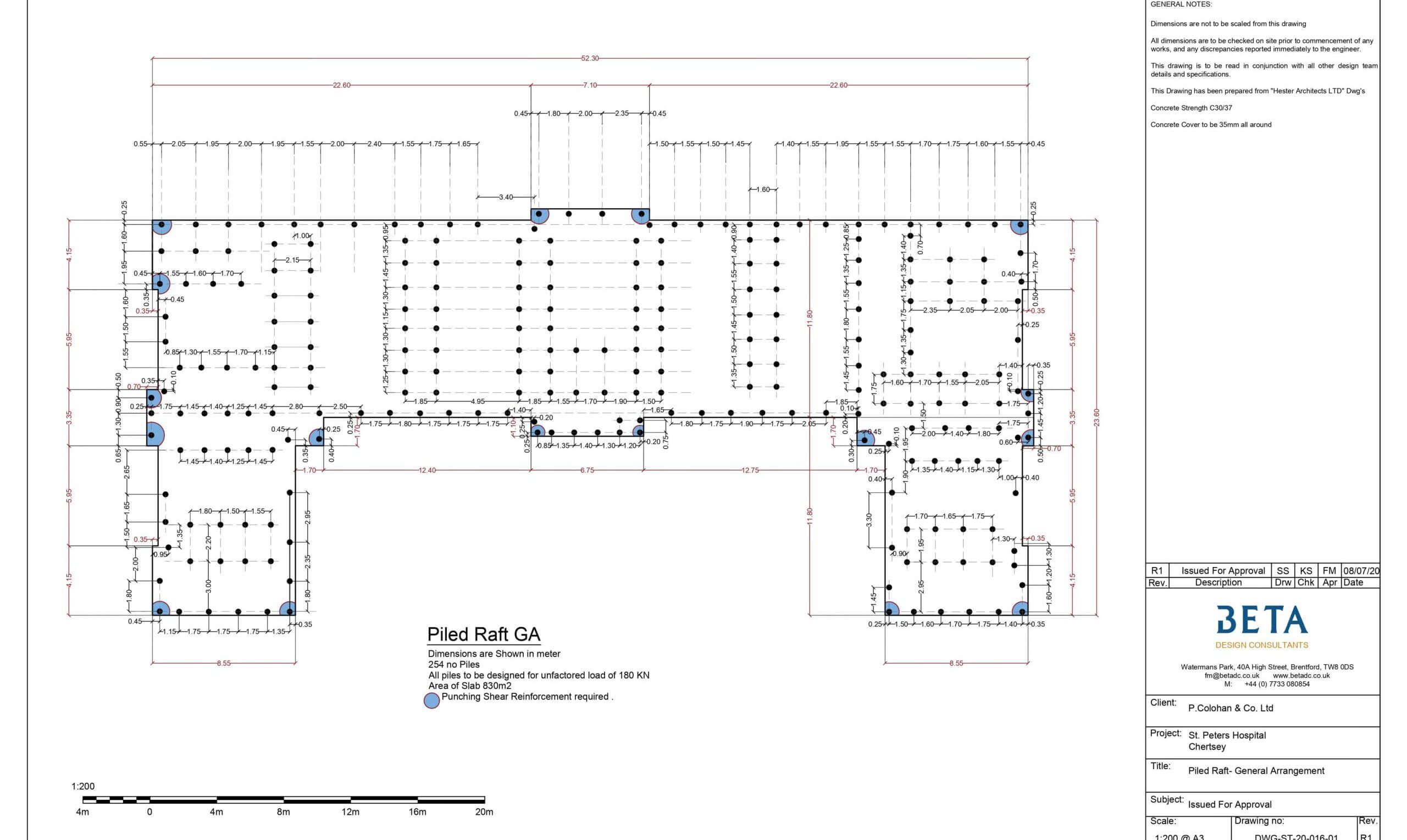

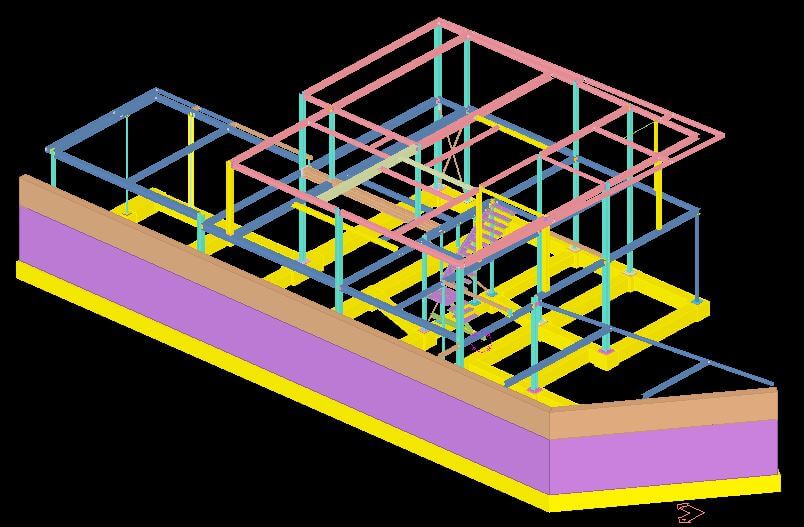

- Design of a piled raft system that can be supported on shallow piles. This system removes the need for a deep piling rig. This system shall replace the traditional system of ground beams on deep piles. This replaces the traditional system of ground beams on deep piles.

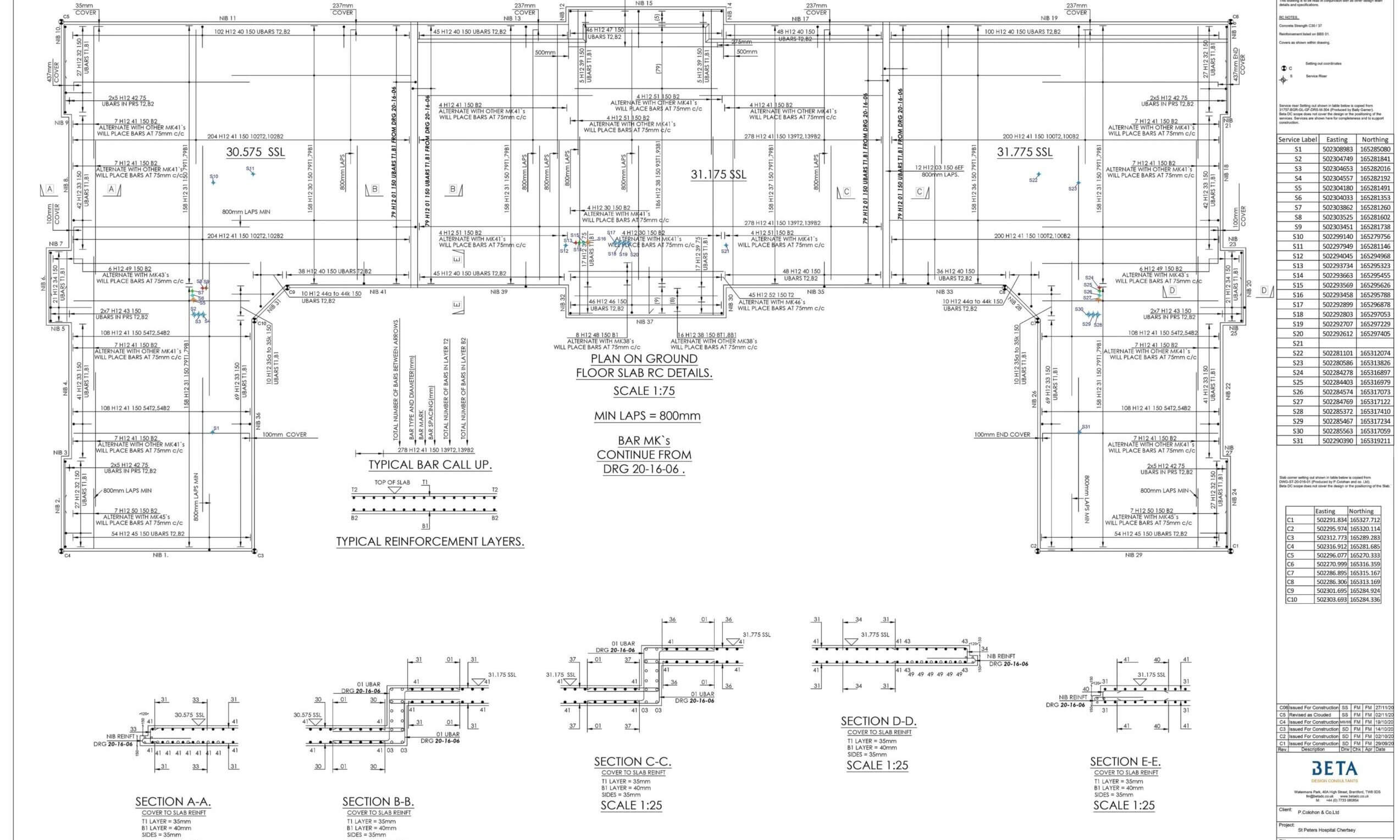

- Detailed construction drawings for 7 rafts including pile setting out and rebar drawings.

Background

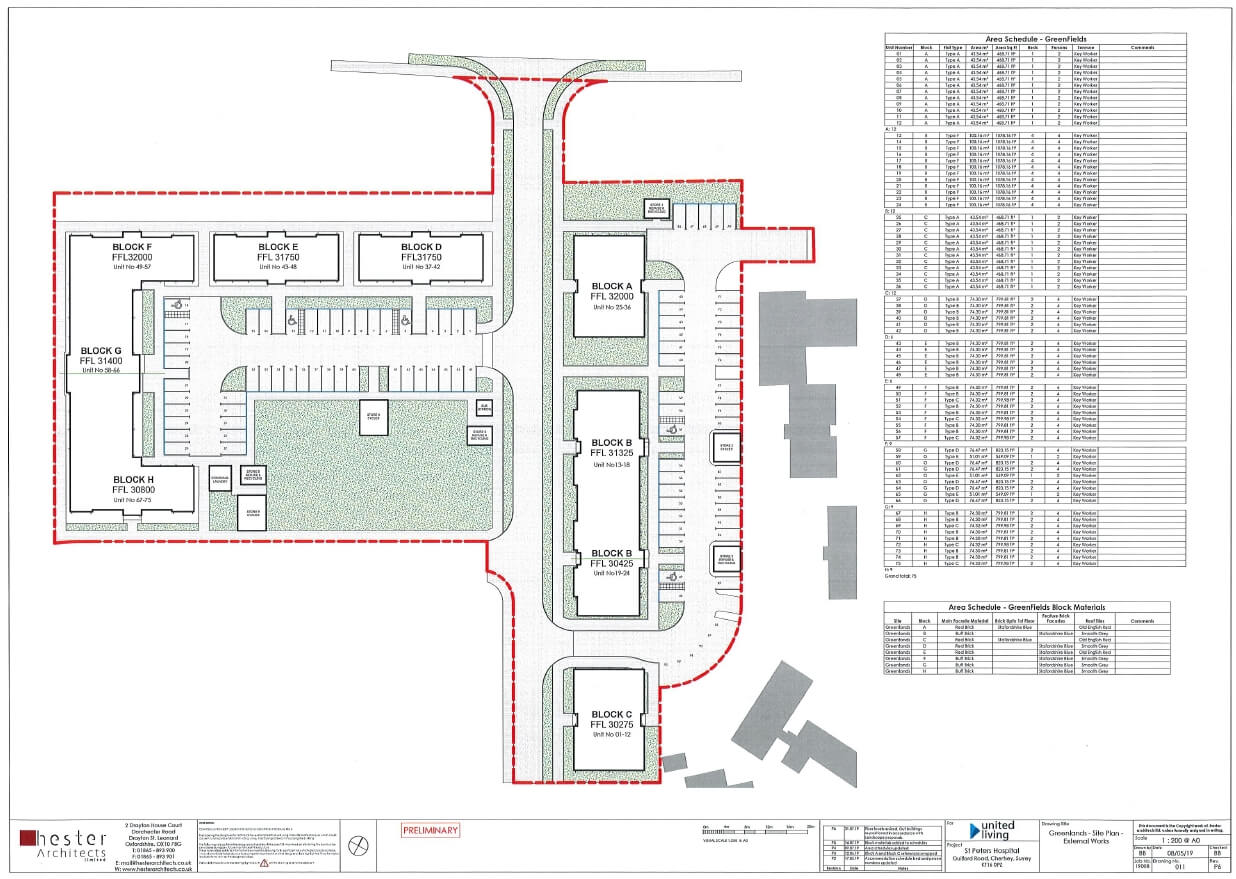

Beta Design Consultants was commissioned to provide the geotechnical analysis and foundations design for the seven blocks of NHS Accommodation at St Peters Hospital in Chertsey. The scheme aims to provide 75 accommodation units in the first stage.

The 7 blocks foundation system would need to respond to the site conditions as laid out in the soil investigation, observe the project tight schedule and save on construction cost to stay within the budget.

BDC re-design of the substructure system lead to 3 weeks savings in the client programme from 14 weeks to 11 weeks.

Beta Solution

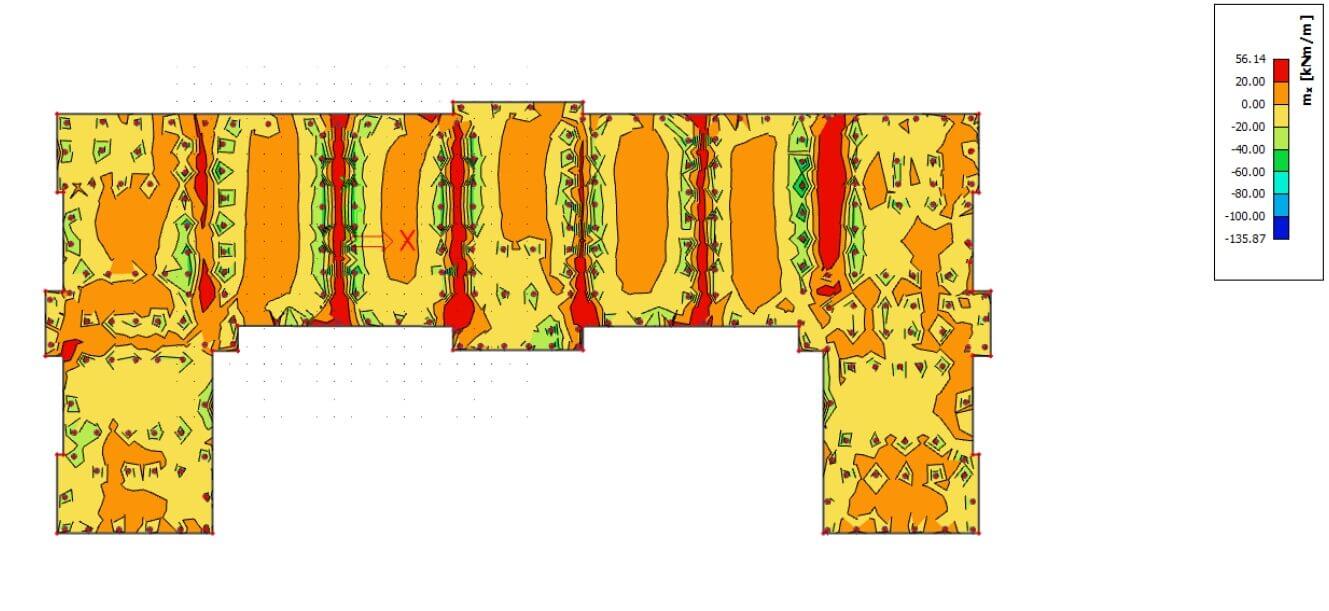

1. Design of Piled Raft System

The initial scheme that was proposed by others was to support each block on a system of ground beams that are supported by deep piles. BDC proposed an alternative system of piled rafts that offers the following advantages:

- Rafts are supported on shallow piles. These can be installed by a “mid-range” piling rig that takes piles to less than 10m deep. The rig would not need a piling mat so this would save a huge cost of the piling platform (usually an excavation of 500mm, compaction of soil that needs to be imported and compacted in layers, cost of nearly 30-40k per block, programme of at least 3 weeks per block).

- The piling programme has more certainty as larger number of small piles are required which are easier to install than deeper piles.

- The rafts require minimum excavation and shuttering compared to ground beams. The reduction in excavation and shuttering lead to huge savings in cost and programme. It is estimated that this has lead to savings of 20-25k per block and programme savings of 8-10 working days.

- The rafts rebar can be laid in a very simple manner. Raft reinforcement is easier to lay than ground beams caged rebars. This is also believed to have contributed to savings in budget and programme.

2. Detailed construction

BDC worked with the piling contractor and the groundworks team to prepare buildable designs for the piled rafts and for the rafts reinforcement.

Client: United Living

Location: Chertsey

Related projects

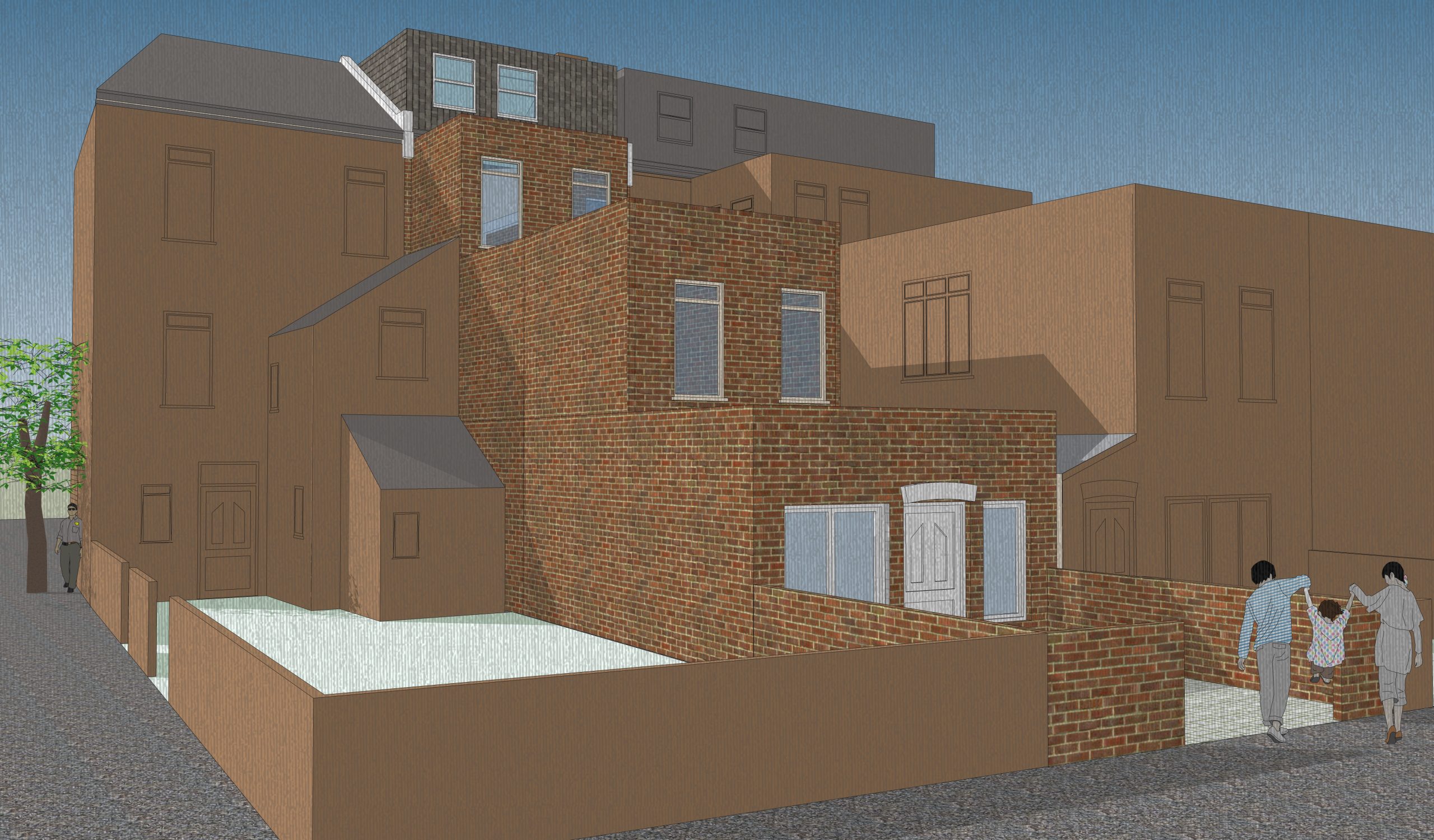

Planning Permission for 21 Boston Road Townhouse Conversion

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

Leisure Swimming Pool House Design

Read More

Engine Yard Punching Shear Slab Strengthening

Read More

Planning Application for Three Story Residential Building

Read More

Helmsley Place-Steel Connections Design and Detailing

Read More

Kennedy Institute Extension - Flat Slab Punching Shear Strengthening

Read More

Planning Permission for a Basement in a Conservation Area

Read More

Structural Repairs of a Listed Building

Read More

One West Point – Design of Support System for Cladding

Read More

Orchard House – RC Column Strengthening using CFRP

Read More

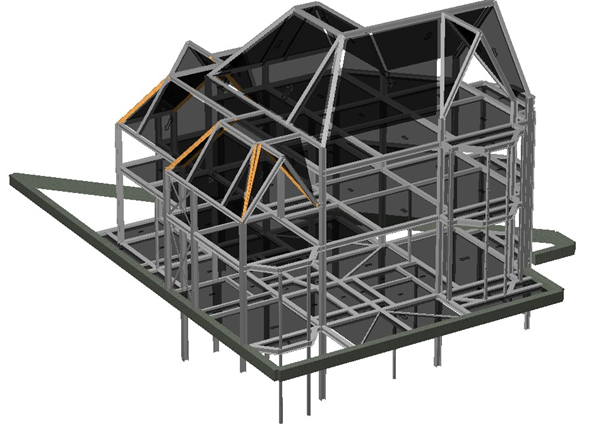

Structural Design of 3 Storey Building

Read More

Queens Rise- Steel Structure Connection Design and Detailing

Read More

Grove Park Gardens 4 Storey Residential Development

Read More

BP Deep Water Sump Assessment and Concrete Repair Design

Read More

Fulham Palace Road Temporary Works Design

Read More

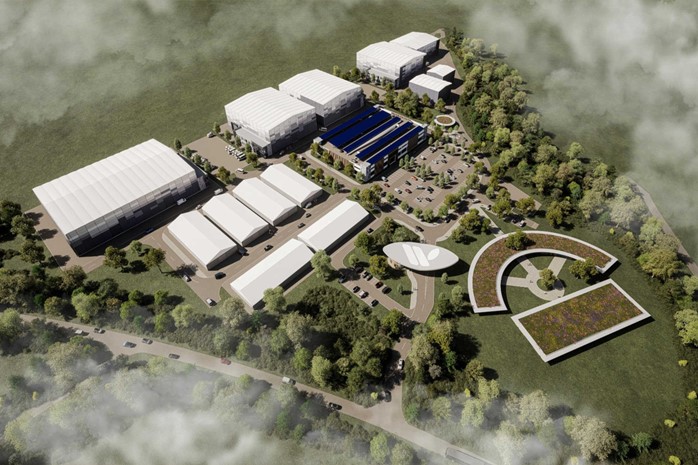

Stage 50 Bovingdon Airfield Studios

Read More

Concept Design of Cité Administrative Koloma

Read More

Coast Drive Visitor Centre, Watersport and Beach Huts

Read More

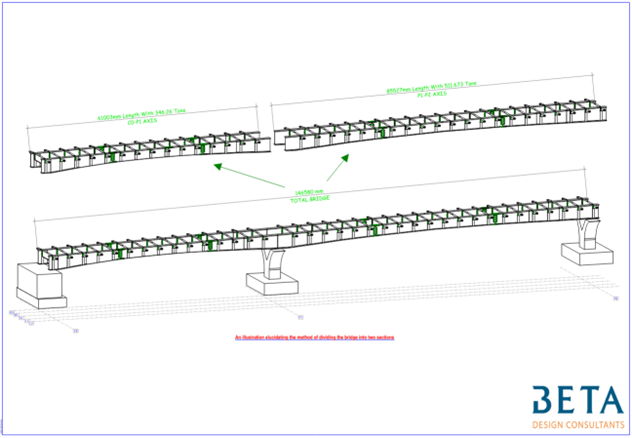

Concept Design of Sedhiou Bridge and Roads Network

Read More

Stage 50 Wycombe Film Studios Village

Read More

CFRP and HPC Concrete Strengthening for Brindleyplace

Read More

CPS House Jacketing to Strengthen RC Beams

Read More

BP Heater Foundation Concrete Repair

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

BP GF Gas Plant – Slug Catcher Foundation Walls RC Repair

Read More

Harwell Campus-Concrete Strengthening

Read More

Planning Permission for New Warehouse, Ealing

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

LABSA Sulphonation Plant Erbil

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

RAAC Investigation and Structural Strengthening

Read More

Nant Melyn Bridge Inspection for Assessment

Read More