Stage 50 Bovingdon Airfield Studios

Background

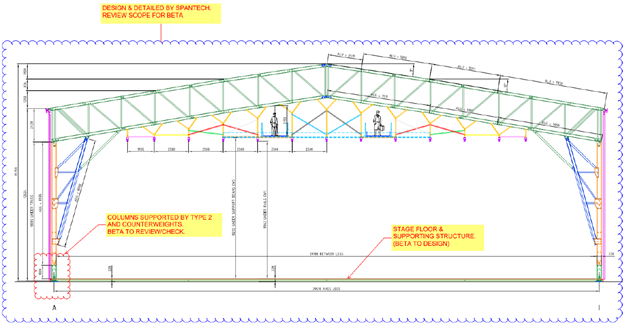

Beta Design Consultants were commissioned by the client, Stage 50, to prepare civil and structural design for the two stages including foundation check (Type 2 assembly pad units – base plates, ring beams, PFC top beams and holding down bolts) and stage floor design at Bovingdon Airfield Studios, Chesham Road, Bovingdon HP3 0GH.

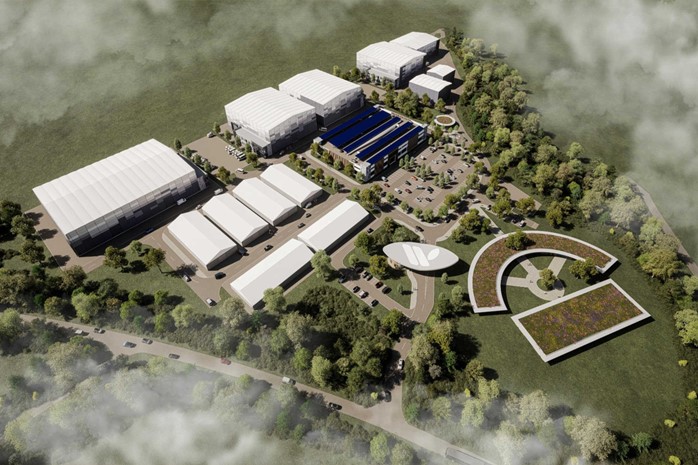

Bovingdon Airfield Studios offers over 100 acres of premium film friendly production facilities. The sound stages are suitable for feature film, HETV, commercials and primetime TV shows with audiences.

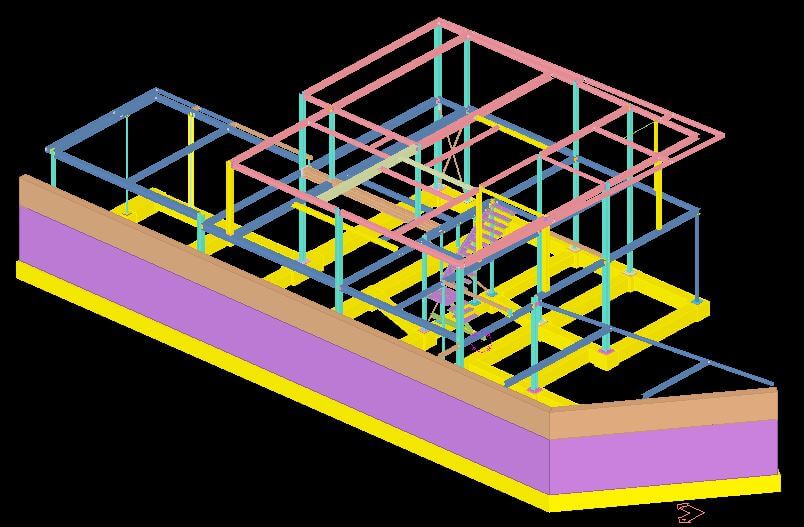

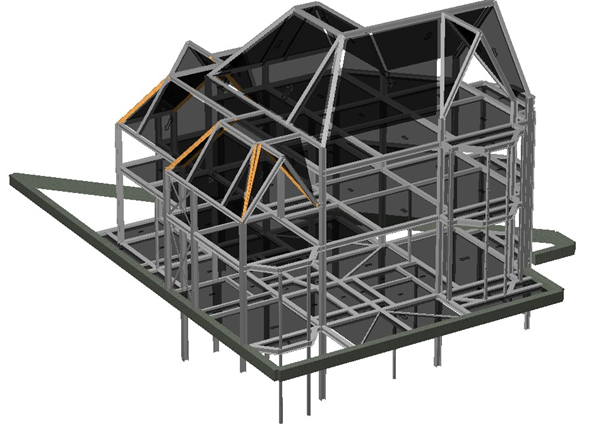

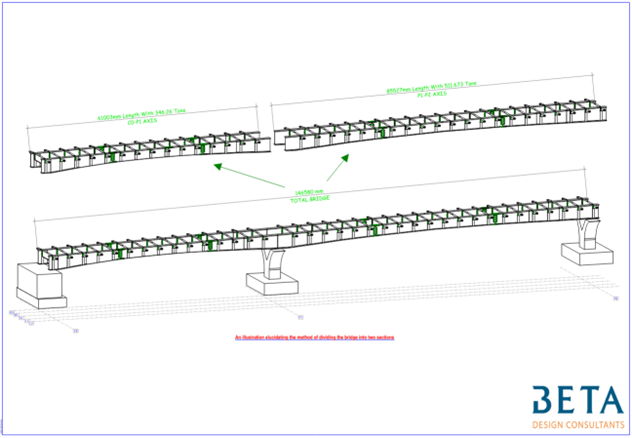

The two stages frames were 40m wide x by 60m long, and 40m wide by 50m long with a total height of 15.759m. The skeleton of the structure was an aluminium frame with truss columns and rafters with frames spaced at 5m centres. The main frame of the structure was supported on an assembled pad unit. The flooring system is based on the use of a skeleton of longitudinal primary SHS beams with transverse SHS beams. The longitudinal and transverse SHS beams formed a consistent grid. The SHS beams were topped with a timber deck floor that is made up of three layers of CLT and 18mm thick birch ply on top. The timber deck layers were staggered in brick pattern and screwed together as well as being fixed to the steel grillage using screws to ensure the timber and steel work together.

The activities included:

- Design of stage floors:

- Cross-laminated timber (CLT).

- Grillage of steel beams (90x90x5 SHS) supporting the stage floor structure.

- Concrete blockworks (440mmx140mmx215) and Forms under the steel structure.

- Design check for Type 2 assembly members:

- Base plate check between the main frame to the substructure.

- Ring beam (50x50x5 SHS) check.

- PFC (100x50x10) top beam.

- Counterweight blocks check for the uplift

Beta Solution

We carried out a structural design for the stage floor for an imposed load of 60kN/m2 acting as a uniformly distributed load over any part of the floor area. Vehicular and machine movements are expected withing the stage, consequently, an axle load of 88.2kN (made up of two concentrated forces spacing 1.0m each or 44.1KN of single point load) is applied over a contact area of 2 wheels each having a surface of 200mm x 200mm to simulate the effects of the vehicle loads (Refer to Design Criteria Document by Beta Design Consultants). Loads from the main frame are transferred to the ground through an assembled pad unit.

Related projects

Action Court Warehouse Extension

Read More

Value Engineering for Warehouse and Office Building

Read More

Planning Permission for New Warehouse, Ealing

Read More

Three Story Warehouse Steel Structure Design

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

LABSA Sulphonation Plant Erbil

Read More

Stage 50 Wycombe Film Studios Village

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

Leisure Swimming Pool House Design

Read More

Planning Application for Three Story Residential Building

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

Helmsley Place-Steel Connections Design and Detailing

Read MoreLondon Hippodrome Roof Extension – Structural Design and Detailing

Read More

Structural Design of 3 Storey Building

Read More

Queens Rise- Steel Structure Connection Design and Detailing

Read More

Grove Park Gardens 4 Storey Residential Development

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More

Concept Design of Cité Administrative Koloma

Read More

Coast Drive Visitor Centre, Watersport and Beach Huts

Read More

Northside Garages Structural Investigation

Read More

Peckham Arch Condition Survey & Life Extension Consulting Services

Read More

Pembroke Road Footbridge - Structural Investigation & Strengthening

Read More

RAAC Investigation and Structural Strengthening

Read More

Concept Design of Sedhiou Bridge and Roads Network

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

United Downs Deep Geothermal Power Plant

Read More

Wycombe Air Park- Data Centre

Read More