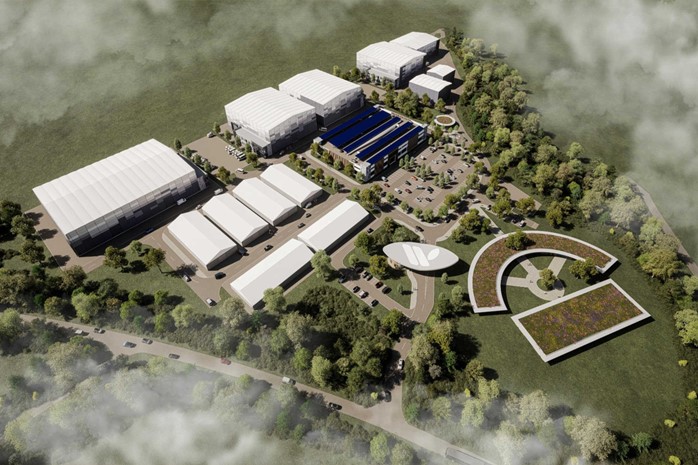

Stage 50 Wycombe Film Studios Village

Scope:

Professional Services to Discharge Planning Conditions

Civil Engineering Design (Roads, Drainage, Cut and Fill Studies)

Flood Risk Assessment

Surface Water Drainage Strategy and SuDS Design

Geotechnical Assessment and Hydrology Study for Drainage into Chalk

Structural Engineering Design for 8 stages including Foundation and Superstructure

Project Description and Scopes:

Beta Design Consultant has completed an important, high value contract on behalf of its major client, Stage 50. Beta was involved in the various stages of this project from Concept Design and Planning Stages to Detailed Design and was appointed to carry out construction support and site supervision until handover.

With almost 295,000 sq. ft of high-quality production space, Wycombe Film studio offers purpose-built professional facilities.

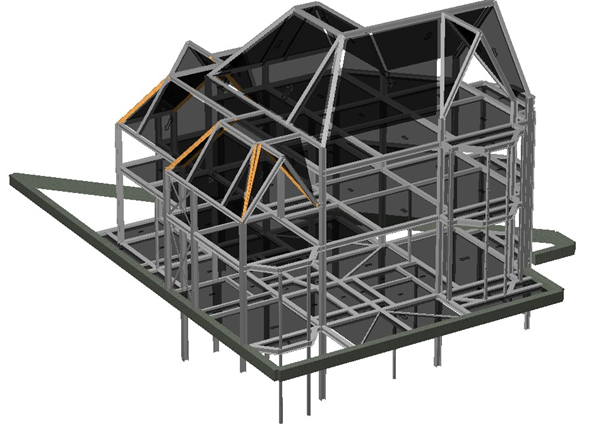

The structural design of the sound stages and workshops lends itself to the market requirements of the film industry, by supporting a modular and sustainable design strategy, maximizing the use of demountable structures and offering expert advice regarding suitable stage floors and suitable foundations for the challenging site that has a history of contamination and known gypsum strata.

The civil engineering design supports the client vision by delivering roadway design in the green-belt site that results in minimum impact regenerating the ex-landfill site to make it suitable for the 10-year life span of the temporary license. Overall, the design helps to confirm the UK as a sustainable film production destination that facilitates the art as a hub for creativity. The scope of the projects is:

- Discharge of Planning Condition relating to a Geotechnical Assessment and Hydrological Assessment of Proposed Drainage into the Chalk

- Structural Design for Foundations and Stages Considering the Modular/Demountable Stages and the Chalk Strata

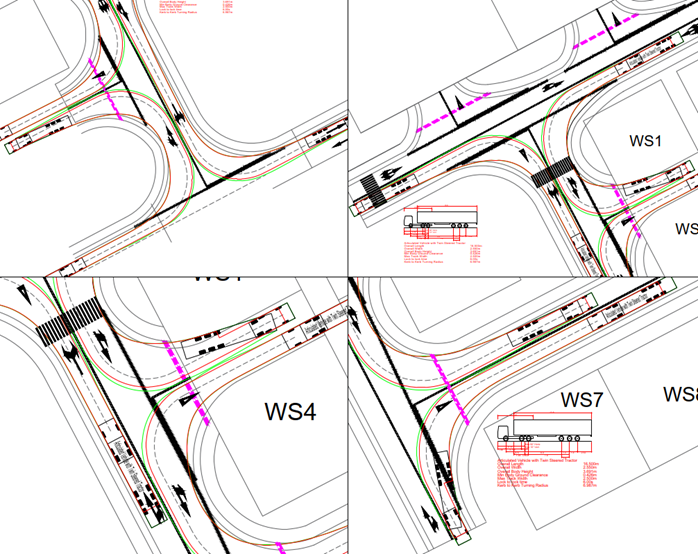

- Infrastructure Planning and Road Design

- Drainage Design and Sustainable Drainage Strategy SuDS

Approach:

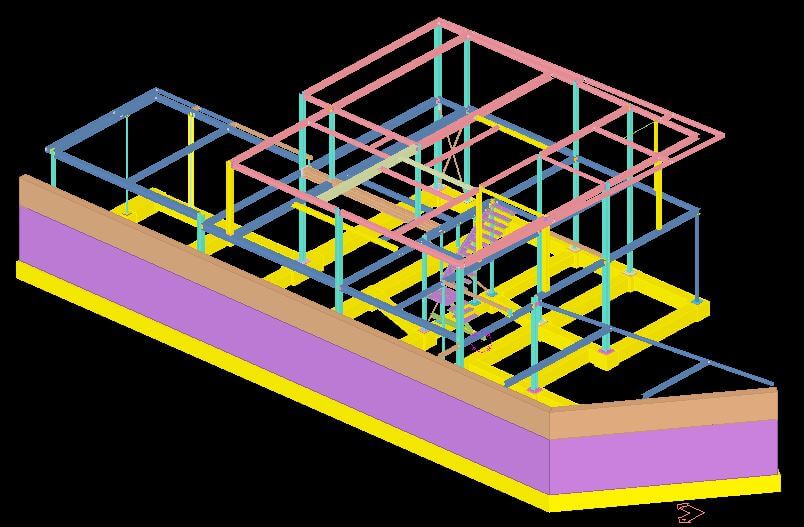

- Structural Design for Foundations and Stages:

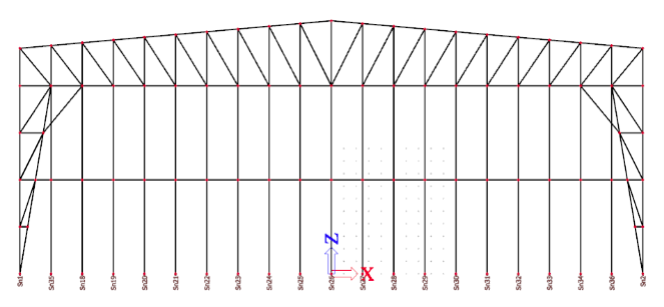

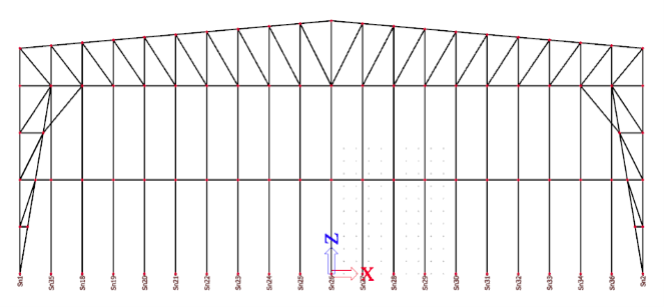

Software Used: Scia and Tekla Tedds

- Designs Checks:

The primary scope involves design checks for the foundation for the Phase 1 stage of the Wycombe Film Studio. This includes;

-Design check of Foundations: BETA perform the structure checks for the foundation as per provided loads and design criteria. The design checks for the foundation shows that the column bases were generously sized.

-Base plate and post installed anchor bolts: The design of the base plates and the anchor bolts were based on the design forces allowing the installation team to install anchor bolts after the stage was set up.

- checks on Ground beams: Beta perform 600 x 600 Ground Beams Design Checks. Ground beams have been provided to act as ties for the foundation, as confinements for the earth fill for the stage area and partly supports the square hollow sections (SHS) supporting the stage floor.

Recommendation:

-Due to the thickness of the foundation (1500mm), anti-shrinkage reinforcement should have been provided to reduce the risk of shrinkage cracking in the foundation. In lieu of this, the contractor has agreed to use fibre-reinforced concrete which is specified to limit the shrinkage of the concrete.

B. Sub-Structural Design:

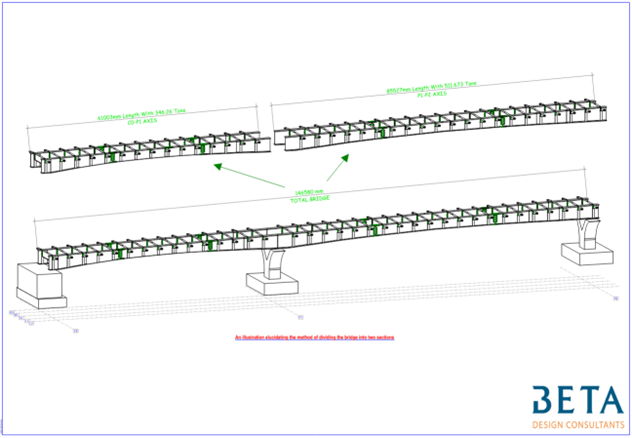

After completion of first stage design check, Beta was reappointed to carry out sub-structural design for the sound stages (50x60). Beta Structural Engineers changed the initially suggested pad foundations with a stirp foundation solution that allows continuous excavation and reduces costs and time of formwork. The foundation supporting the stage frames (2250mm wide reinforced concrete strip footing to support the side and corner columns; and 1700mm wide strip footing to support the gable columns).

For initial stages, a modular steel stage was used but that turned out to be really labour intensive and resulted in quality control challenges. For later stages, a reinforced concrete slab was used – 250mm thick

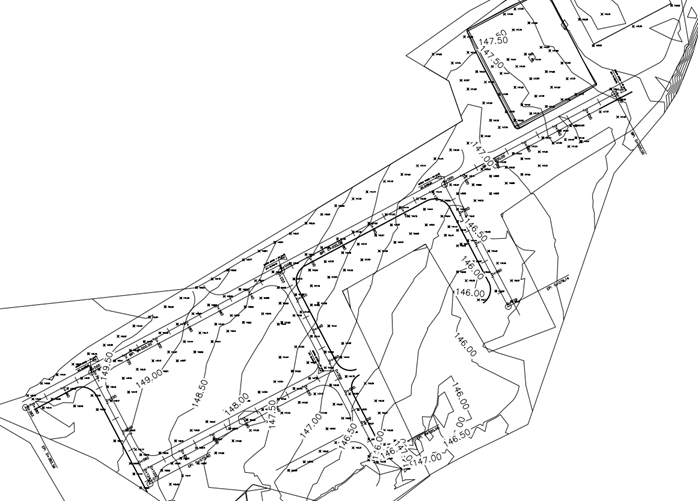

2. Infrastructure Planning and Road Design:

Scope: Develop a functional road network integrated with the site’s drainage system and suited to challenging ground conditions.

Project Overview

Beta Design delivered a sustainable road design that addressed site-specific challenges, including a chalk layer with clay and flints and the need for stormwater management integration. The design incorporated permeable pavements, filter drains, and grading to support the Surface Water Drainage Strategy.

Challenges & Solutions

Geotechnical Conditions:

Extensive soil testing informed flexible pavement designs to ensure long-term durability on clay and flint subgrades.

Drainage Integration:

Roads featured permeable paving and filter drains to tie into attenuation tanks and basins, reducing surface water runoff.

Topography Management:

Grading optimized water flow while minimizing earthworks and avoiding poorly drained areas.

3. Drainage Design

Scope: To create a sustainable stormwater drainage system for the development site, meeting regulatory and environmental standards and allowing for global warming while containing peak flow within the site.

Project Overview

Beta Design Consultants designed the stormwater drainage system, ensuring compliance with CIRIA C753 – The SuDS Manual. The proposed Surface Water Drainage Strategy incorporated sustainable drainage solutions (SuDS), including:

Filter drains

Green roofs

Permeable paving

Attenuation tanks

Geocellular storage tanks

A large soakaway under the surface car park.

These features ensured the system effectively attenuated surface water for storm events up to and including the 1-in-100-year return period, plus an allowance for climate change.

Design Challenges

The site presented a unique challenge due to the presence of a chalk layer under naturally deposited superficial layers consisting of clay with flints, limiting infiltration and raising concerns about effective water drainage.

Approach

To address these challenges, different testing was conducted;

Borehole and Soil Testing

Soil infiltration tests were performed at various locations to determine the site’s drainage characteristics.

Testing revealed variability in infiltration rates, necessitating further evaluation for soakaway compatibility.

Soakaway Feasibility Studies

Multiple soakaway tests were carried out to identify suitable locations for soakaways. Areas with the most favourable infiltration rates were prioritized in the design.

Integrated SuDS Strategy

A combination of attenuation tanks, permeable surfaces, and green infrastructure was implemented to reduce runoff volumes and improve water quality. The use of geocellular tanks provided additional storage, preventing surface water flooding.

Results:

- Design of foundations of the stages with the roads design to reduce construction work, cut and fill and utilized sustainable practices to provide significant carbon footprint reductions. Examples included using strip foundations that removed need for shuttering and edge protection and formwork/falsework, as well as using Eco Pact RC mixes from Aggregate Industries with nearly 40% carbon savings for less than 10% increase in concrete cost.

- We integrated cutting-edge technology in ground improvement and soil stabilisation, maximizing use of laboratory trial soil-mixes, field tests and pilot trials on site to ensure the ex-landfill site is developed to support new loads. We adopted a cost-effective method for soil stabilisation and ground improvement using evidence-based soil-mix design to reduce cost and impact of civil works

- The design delivered a durable and sustainable road network that complemented the drainage strategy, reduced flood risks, and ensured compliance with relevant standards.

- A robust and resilient stormwater management system was delivered, compatible with the site’s challenging geological conditions. The design achieved regulatory compliance and aligned with sustainable development principles. The strategy mitigates flood risks, while providing long-term environmental benefits, including groundwater recharge and biodiversity enhancement.