Action Court Warehouse Extension

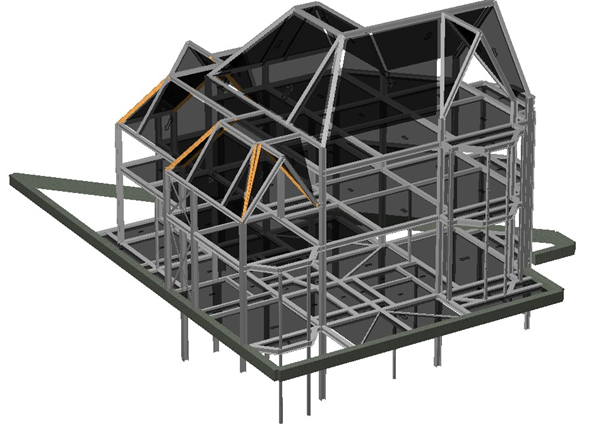

Beta Scope

- Structural design for the portal frame warehouse extensions

- Strengthening of the existing structural frame (portal frame single storey warehouse)

- Secondary steel design.

- Preparing fabrication package for new frame, strengthening works and the secondary steel.

Background

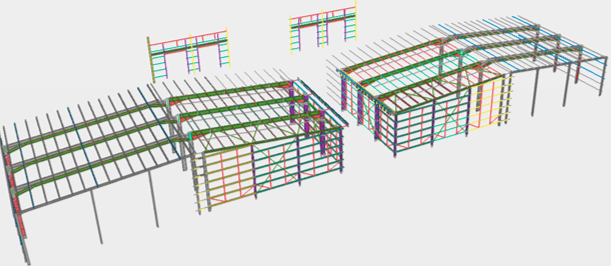

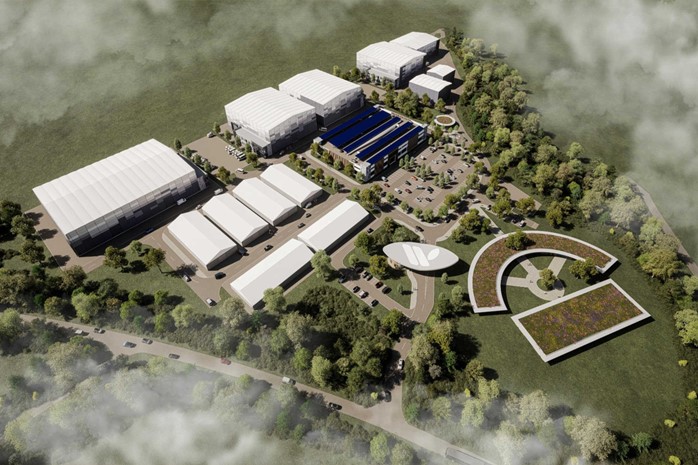

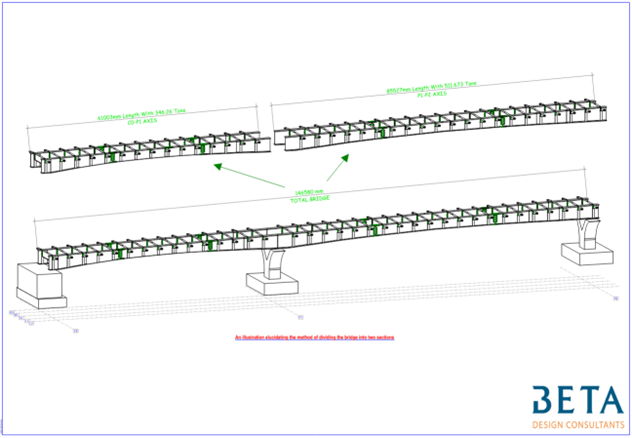

Beta Design Consultants were commissioned by Lomas Steel Structures and Glencar Construction to provide the structural steel design for the two units warehouse extension. The client brief was extending an existing warehouse by modifying frames that currently span half the span of the final span. The client aim was to reuse the existing side columns and rafter beams of the short span and strengthen them so they could be part of the new frame. The intention is to achieve this full span without any internal columns or foundations.

Beta Design Consultants instructed a surveying company to carry out a 3D survey for both Existing Units to ensure the new extensions and strengthened frame members are matching with the existing so that accurate fabrication drawings can be produced within 1mm-5mm tolerance.

Beta Solution

Beta Structural Engineers established the conceptual and preliminary design, which identified the approximate member sizes and the steel quantities. Based on that, our immediate client, Lomas Steel Structures put in their tender for D&B and secured the project. Beta provided the concept design to prove to the client that such a solution was workable.

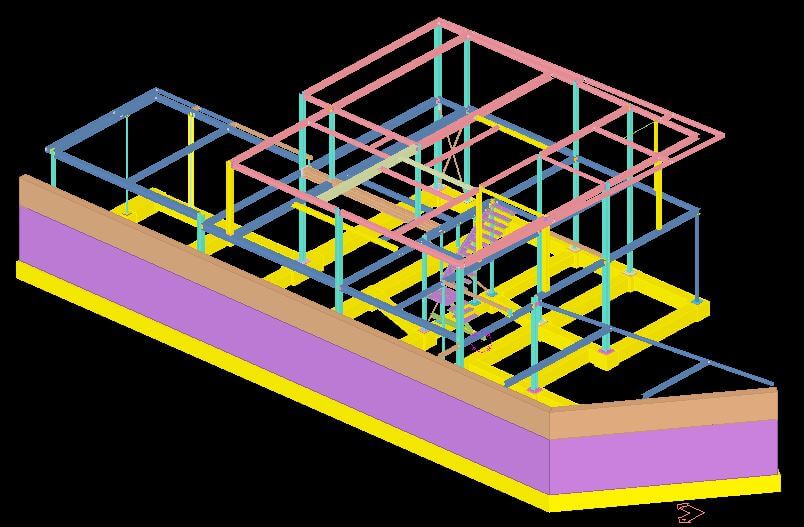

This was followed by a detailed structural analysis, with the use of Scia Engineer, to define the exact sizes and to standardize the sections for efficient fabrication and installation.

Practical Details

Scia Engineer was used for the modelling, analysis and design of the structure according to the EN 1993 British BS-EN NA. Our design made use of guidance in the Eurocode to consider the nominal stiffness of base plates and allow for 20% of the column stiffness when checking deflections. This allowed us to produce a very efficient structural design.

Tekla Structures was used to produce fabrication shop drawings for the primary and the secondary steel for the extension and the strengthening and any modifications in the existing/new openings for the both units.

Idea Statica was used to design all steel to steel connections and achieve maximum standardisation possible to reduce cost of fabrication and time of installation. All the cold rolled secondary steels (purlins, rails, bracings) were designed using Ayrshire software.

Our engineers were on site to support the client and the contractor, attend design meetings, support the surveying team and answer any technical queries.

Measured deflections after removing the mid-column were compared with calculated deflection as per the design. The comparison verified that the design values were matched during installation.

Client: Glencar Construction & Lomas Steel Structures

Architect: UMC Architects

Location: Ashford, London

Related projects

Value Engineering for Warehouse and Office Building

Read More

Planning Permission for New Warehouse, Ealing

Read More

Three Story Warehouse Steel Structure Design

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

LABSA Sulphonation Plant Erbil

Read More

Stage 50 Bovingdon Airfield Studios

Read More

Stage 50 Wycombe Film Studios Village

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

Leisure Swimming Pool House Design

Read More

Engine Yard Punching Shear Slab Strengthening

Read More

CPS House Jacketing to Strengthen RC Beams

Read More

BP Deep Water Sump Assessment and Concrete Repair Design

Read More

Planning Application for Three Story Residential Building

Read More

BP Heater Foundation Concrete Repair

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

BP GF Gas Plant – Slug Catcher Foundation Walls RC Repair

Read More

Harwell Campus-Concrete Strengthening

Read More

Helmsley Place-Steel Connections Design and Detailing

Read More

Kennedy Institute Extension - Flat Slab Punching Shear Strengthening

Read MoreLondon Hippodrome Roof Extension – Structural Design and Detailing

Read More

Orchard House – RC Column Strengthening using CFRP

Read More

Structural Design of 3 Storey Building

Read More

Queens Rise- Steel Structure Connection Design and Detailing

Read More

Stanmore House Strengthening

Read More

Bus Depot Electrification Harrow

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More

Concept Design of Cité Administrative Koloma

Read More

Coast Drive Visitor Centre, Watersport and Beach Huts

Read More

Structural Assessment of Henley Masonry Arch Bridge

Read More

Northside Garages Structural Investigation

Read More

Peckham Arch Condition Survey & Life Extension Consulting Services

Read More

Pembroke Road Footbridge - Structural Investigation & Strengthening

Read More

RAAC Investigation and Structural Strengthening

Read More

Concept Design of Sedhiou Bridge and Roads Network

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

United Downs Deep Geothermal Power Plant

Read More

Wycombe Air Park- Data Centre

Read More

CFRP and HPC Concrete Strengthening for Brindleyplace

Read More

Planning Permission for 21 Boston Road Townhouse Conversion

Read More

Planning Permission for a Basement in a Conservation Area

Read More

One West Point – Design of Support System for Cladding

Read More