Offshore Platforms

Civil and Structural Engineering Consulting Services

Beta Design Consultants and Structural Engineers support operator and their EPC contractors during offshore platforms design, maintenance, and decommissioning ensuring the safety, integrity, and longevity of these structures throughout their lifecycle.

Our management team and design consultants have been supporting operators and EPC contractors around the world on projects during the various stages of the oil rigs lifecycle. We have also been involved in a variety of roles including PMC, pre-feed, FEED, EPC and asset refurbishment stages. Please refer to our clients page for a list of our energy clients which include Bechtel, BP, DNV, KBR, Orsted, Wood Group and a long list of supply chain partners.

Projects include:

|

Beta Client |

Project |

Operator/End Client |

Period |

|

Confidential |

N’Kossa Offshore Barge – Concrete Assessment |

Chevron, Congo |

2023 |

|

Confidential |

Prions D Offshore Platform – Splash Zone Legs Strengthening (Bonded Plates to strengthen sections) |

Energean, Greece |

2022 |

|

Confidential |

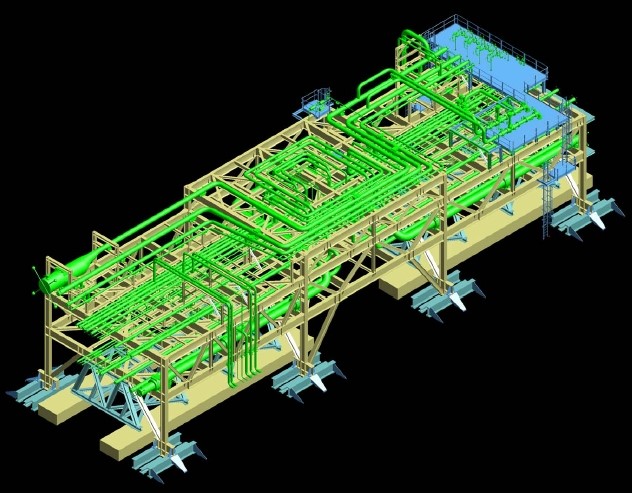

Floating Production Module Design |

Various |

2021-2023 |

|

Confidential |

Offshore Substation Platform |

Various |

2020-2022 |

|

Bechtel |

Hail and Gisha FEED – Concept Design of Topsides |

ADNOC, UAE |

2018-2020 |

|

Wood Group |

Ivar Aasen Offshore Platform – Connections Design |

Det Norske |

2013-2015 |

|

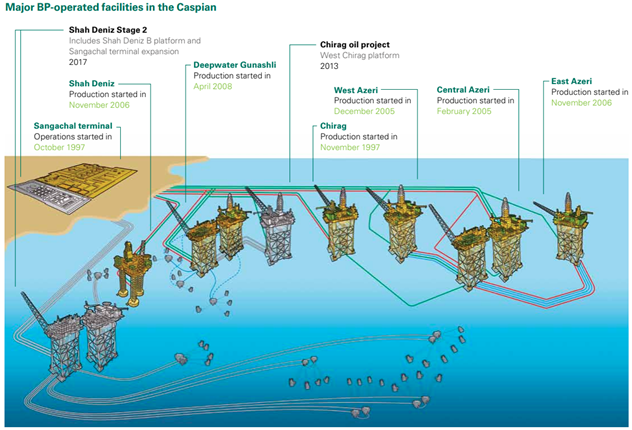

KBR UK |

Shah Deniz 2 Offshore Platform – Connections |

BP |

2013-2014 |

|

DNV GL |

Structural Integrity Management Offshore Platforms |

BP, BG, CSL, Premier Oil |

2011-2013 |

|

KBR |

Gorgon Offshore LNG Project EPC |

Chevron, Australia |

2010- 2011 |

|

Bechtel |

Miskar Platform Compressor Module Design |

BG Tunisia |

2008-2009 |

1. Design Phase:

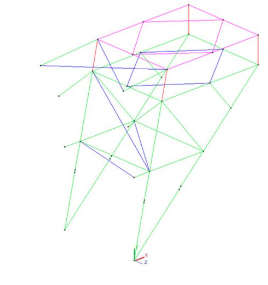

- Structural Analysis: Our structural engineers analyze loads, stresses, and strains on the platform structure to ensure it can withstand various environmental conditions such as waves, wind, currents, and seismic activity. We carry out detailed analysis including pushover analysis, fatigue analysis, lifting studies, transport studies and prepare detailed packages including connection design and construction/fabrication packages. Our engineers have carried out the structural analysis for new platforms that include:

- Ivar Aasen in the Norwegian Continental Shelf of the North Sea

- Shah Deniz 2 twin platform in the Caspian Sea.

- Hail and Gasha Concept Design of Topsides

- Material Selection: We support clients in the choice of appropriate structural materials considering factors like corrosion resistance, strength, and durability in marine environments. The advice we offer balances cost with weight considerations to achieve operational needs. In one case, we compared two solutions from high strength S460 carbon steel against duplex stainless steel and advised the client that S460 carbon steel with the right protection is our recommended option.

- Design Development: Our Structural Engineers are embedded within project teams to coordinate the design with other disciplines such as mechanical, electrical, and marine/weight engineers to integrate structural components seamlessly into the overall platform design. In most offshore design projects, our consultants were integrated within the project team either by being seconded to clients offices or visit clients offices at regular stages for design meetings.

- Regulatory Compliance: Our Structural Engineers ensure that the design meets all relevant industry standards and regulatory requirements for safety and environmental protection. We ensure compliance and approvals by insurance companies and operators (clients) engineers. This is usually achieved through the experience gained working on various structural codes such as API, DNV and Norske Standards as well as the Structural Eurocodes and American Standards (AWS, AISC, ASCE). Our engineers also have expertise in the AS4100 and the South African Standards SANS 10162.

2. Maintenance Phase:

- Inspection and Monitoring: Our Structural Engineers have extensive experience in conducting regular inspections to assess the condition of the platform structure, identify any signs of corrosion, fatigue, or damage, and making recommendations for monitoring its performance over time. Our consulting engineers have supported asset owners and structural integrity teams as well as repair contractors in various jurisdictions to support them in maintaining assets in a safe operating condition. Operators as well as investors have called on our expertise during the change of ownership of some assets and in some cases we had to give an opinion regarding structural issues within very tight timeframes to advise investors of structural issues that may lead to extensive investments as opposed to regular intervention.

- Repair and Retrofit: Our consulting structural engineers develop repair and retrofit strategies to address any structural deficiencies or damage, ensuring the continued integrity and safety of the platform. We carry out non-destructive testing including ultrasonic testing and steel coating assessment to advice clients on section loss and condition of coating. We then develop either a traditional solution that entails either plating or hot-works or a novel solution that relies on the use of bonded systems. Our consulting engineers are experienced in the use of FEMAP software and the application of DNV GL-RP-C301 Recommended Practice for the Bonded Repair of Steel Structures as well as Bureau Veritas BV 613-NI_2015-05 Guidance Note on the use of Adhesive Joints and Patch Repairs. We have successfully used advanced FE softwares to work out stresses and justify the number of layups needed as well as study the bond stresses and ensure the proposed repairs are verified.

- Corrosion Protection: Our consulting structural engineers implement corrosion protection measures such as coatings, cathodic protection systems, and corrosion inhibitors to mitigate the effects of corrosion on the structure. The visual inspection, non-destructive testing and section loss structural assessment will feed into developing a solution that ensures the longevity of the asset.

structure considering corrosion section loss

- Structural Health Monitoring: Our consulting structural engineers develop the specifications for structural health monitoring and work with specialist supply chain to support clients during the installation of sensors and monitoring systems to continuously monitor the structural health of the platform and detect any abnormalities or degradation in real-time.

management services to DNV GL

3. Decommissioning Phase:

- Structural Integrity Assessment: Our Structural Engineers have assessed the structural integrity of the platforms to determine the most effective decommissioning method, considering factors such as structural condition, environmental impact, and cost-effectiveness.

- Demolition Planning: Our Structural Engineers have developed demolition plans and procedures to safely and efficiently dismantle the platform structure, taking into account factors such as environmental regulations, safety protocols, and logistics.

- Environmental Considerations: Our Structural Engineers ensure that decommissioning activities are carried out in compliance with environmental regulations and minimize the impact on marine ecosystems.

- Risk Management: Our Structural Engineers identify and mitigate potential risks associated with decommissioning operations, such as structural collapse, oil spills, or damage to marine habitats.

Overall, Beta Consulting Structural Engineers have played a crucial role in the entire lifecycle of offshore platforms, from initial design and construction to maintenance and eventual decommissioning, ensuring the safety, reliability, and environmental sustainability of these critical offshore structures. If you are an operator or a contractor that require specialist consulting structural engineering input, you can rely on our professional expertise for confidential expert advice.