Our Civil Engineering design engineers play a crucial role in the studies related to grading, cut, and fill in all types of civil engineering projects. These studies involve the analysis and design of the earthwork required for site preparation, including the excavation of soil (cut) and the placement of soil (fill) to create a desired topography for a construction project.

There has been a great focus recently on the value of minimum intervention and working with the land topography to reduce cut and fill. Whether a new road is being laid or a new development is being created, our consultants optimize the earthworks movement via careful consideration of the existing grading, working with the existing slopes, introducing mimiumn intervention measures (e.g. dwarf retaining walls, working with maximum reasonable slopes) to ensure cut and fill amount are kept to a minimum.

This approach not only reduces cost, has minimum carbon footprint, but also results in huge savings in programme and reduced maintenance and repair costs.

We share samples of the contributions of our civil engineering designers in these studies, along with examples of their impact on cost and program.

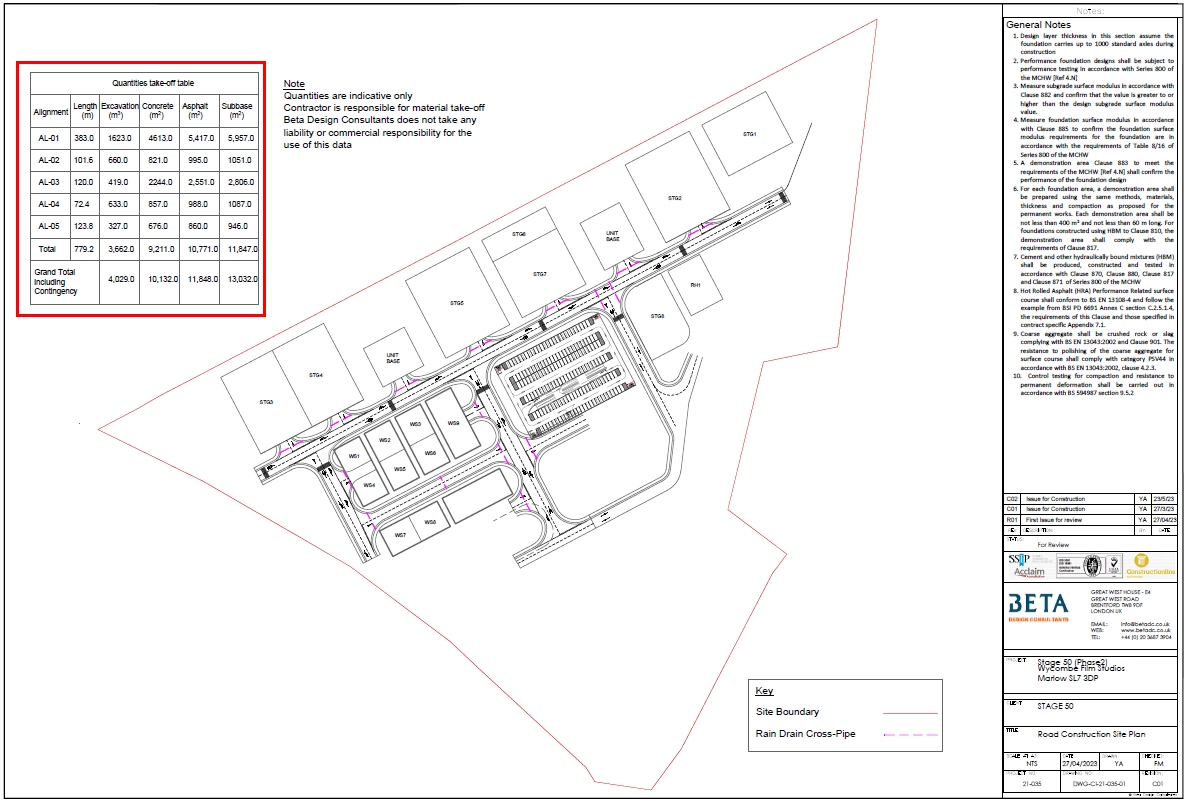

- Site Analysis: our Civil Engineers conduct a thorough site topographic survey followed by site analysis to assess the existing topography, soil conditions, and any potential constraints or environmental considerations. This analysis helps determine the scope of grading required and informs the design process. For example, in Wycombe Air Park Film Production village, our engineers worked out the minimum made ground and top layer that needs to be removed to introduce the new road layout, this was followed by a minimum layer of fill/cut as and where required to work with the topography and introduce the roads network.

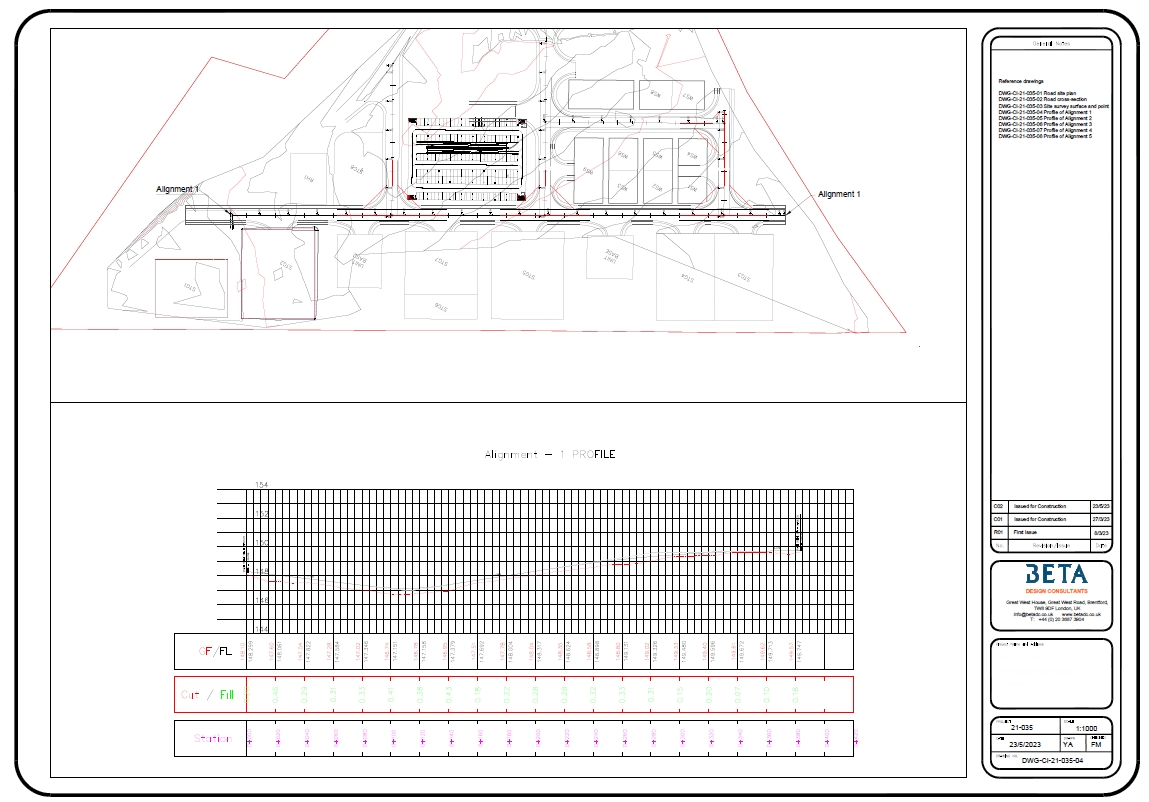

Figure 2: Topographical survey and site analysis by Beta Design Consultants - Earthwork Calculations: Our Civil Engineers perform calculations to determine the volume of cut and fill required to achieve the desired grading. Advanced software programmes (e.g. Civil 3D) make this operation automated and allow optimization in a very quick design flow. This involves analysing the existing site elevations and the proposed final elevations to calculate the difference in elevation and the corresponding volume of soil to be moved. Our design engineers make a point of including all estimated cut and fill quantities in design documents to allow proper planning, accurate budgeting and reasonable tendering by interested contractors. It is always worth mentioning that final quantities depend on actual works on site but having an “estimated” bill of quantities is the least that a design engineer can do to help the contractor price the works accurately and reasonably manage programme and budget.

- Designing Slopes and Profiles: Our Civil Engineers design the slopes and profiles for the cut and fill sections to ensure stability and safety. The design considers factors such as soil properties, groundwater conditions, and the intended use of the graded areas. Slopes and gradients are chosen based on the intended use, with reference to clients requirements and local regulations. This is reviewed in line with the topography to develop a profile for various segments. Standardisation of various segments is weighed up against creating more different profiles to optimize cut and fill quantities.

Figure 3: Slopes and profiles based on site topography and analysis by our consultants - Cost Estimation: Grading, cut, and fill studies have a significant impact on project costs. By accurately determining the volume of cut and fill required, our civil engineers can estimate the quantity of materials needed and associated costs. For example, excessive cut or fill may require additional material transportation, disposal, or import, leading to increased costs. Excessive fill also have similar associated costs so a balanced optimization is key and this is where our experience on site combined with our expertise in using the latest BIM and civil modelling softwares come handy to advise our clients and project teams.

- Program Management: Grading, cut, and fill studies influence the project schedule or program. Earthwork activities, such as excavation and embankment, can be time-consuming, especially if large volumes of soil need to be moved. Our Civil Engineers consider the program requirements, equipment availability, and sequencing of earthwork activities to optimize the construction timeline. Our design records always make clear reference to the required quality control measures, such as CBR testing, plate load testing, method of compaction, layers specifications, so that the contractor can duly allow for all such inspections and durations needed for notifications in their Inspection and Testing Plans.

Figure 4: Cut and Fill quantities are advised to be shown on drawings by the design engineer

- Beta Design

Our involvement in the cut and fill studies have resulted in significant cost savings to our clients. In Wycombe Air Park Film Production Village, each of the sound stages required a building pad with a level surface. After conducting grading studies, our civil engineers determined that if the sound stage level followed the lower limit, a significant amount of cut would be needed, reducing fill but resulting in excess materials that need to be disposed offsite. It also creates drainage issues with risk of flooding. Following the higher level would result in fill material to achieve the desired level, however considering that the sound stage floor sub-base needed to be compacted anyway to deliver the required allowable bearing, it was recommended that the whole sound stage be raised using a ramp and raising the foundations to act as retaining walls for this fill.

We worked with the client to identify material Costs as importing large volumes of fill material from off-site suppliers can increase the project cost due to transportation expenses and material costs.

Our consulting civil engineers have been involved in the design and site supervision of a large number of projects which has made them fully aware of cost and program Impact of the design decisions made during grading, cut, and fill studies:

- In some cases, the required grading involves substantial cut and fill operations, it may take a considerable amount of time to excavate and place the soil, leading to schedule delays.

- The availability of earthmoving equipment and resources may influence the construction timeline. If the project requires a large number of machines for earthwork, their availability and coordination become critical factors in the program management.

By conducting thorough grading, cut, and fill studies, our civil engineers can optimize the design, minimize unnecessary earthwork, and ensure cost-effective construction while adhering to the project's schedule.