LABSA Sulphonation Plant Erbil

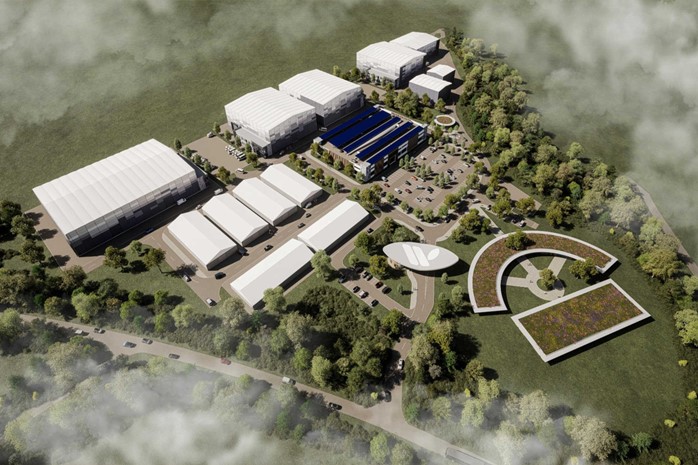

Beta Design Consultants acted as the Consulting Engineers for the feasibility, design and procurement support of this strategic plant in Erbil to support the Northern Kurdistan Region as well as the whole of Iraq with potential for export to Turkey and the region.

The LABSA plant was designed to rely on LAB from oil-rich Iraq existing refineries, with a back up plan to rely on imports from Iran if needed. The LABSA would then be exported to existing detergents factories.

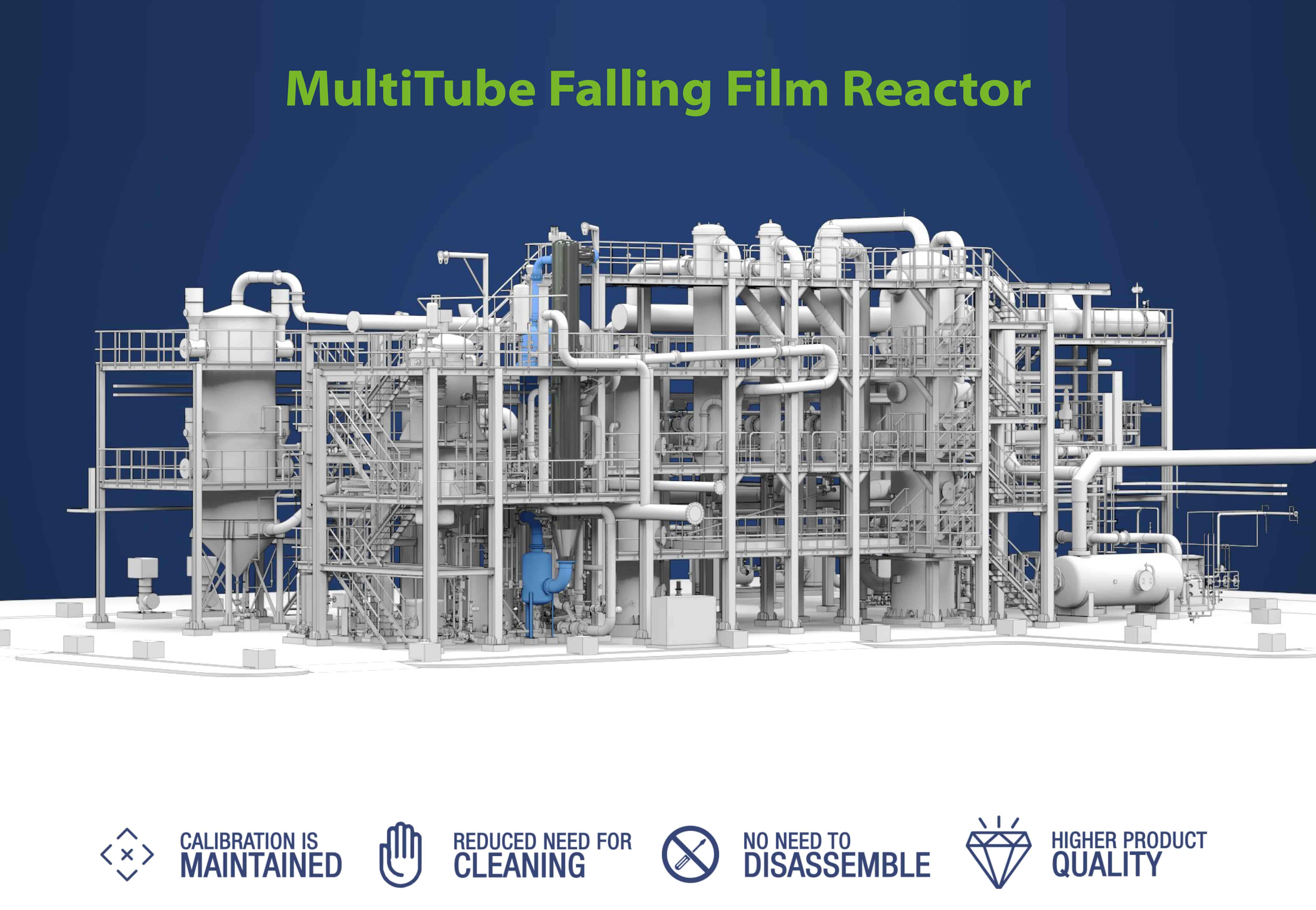

Existing Processes

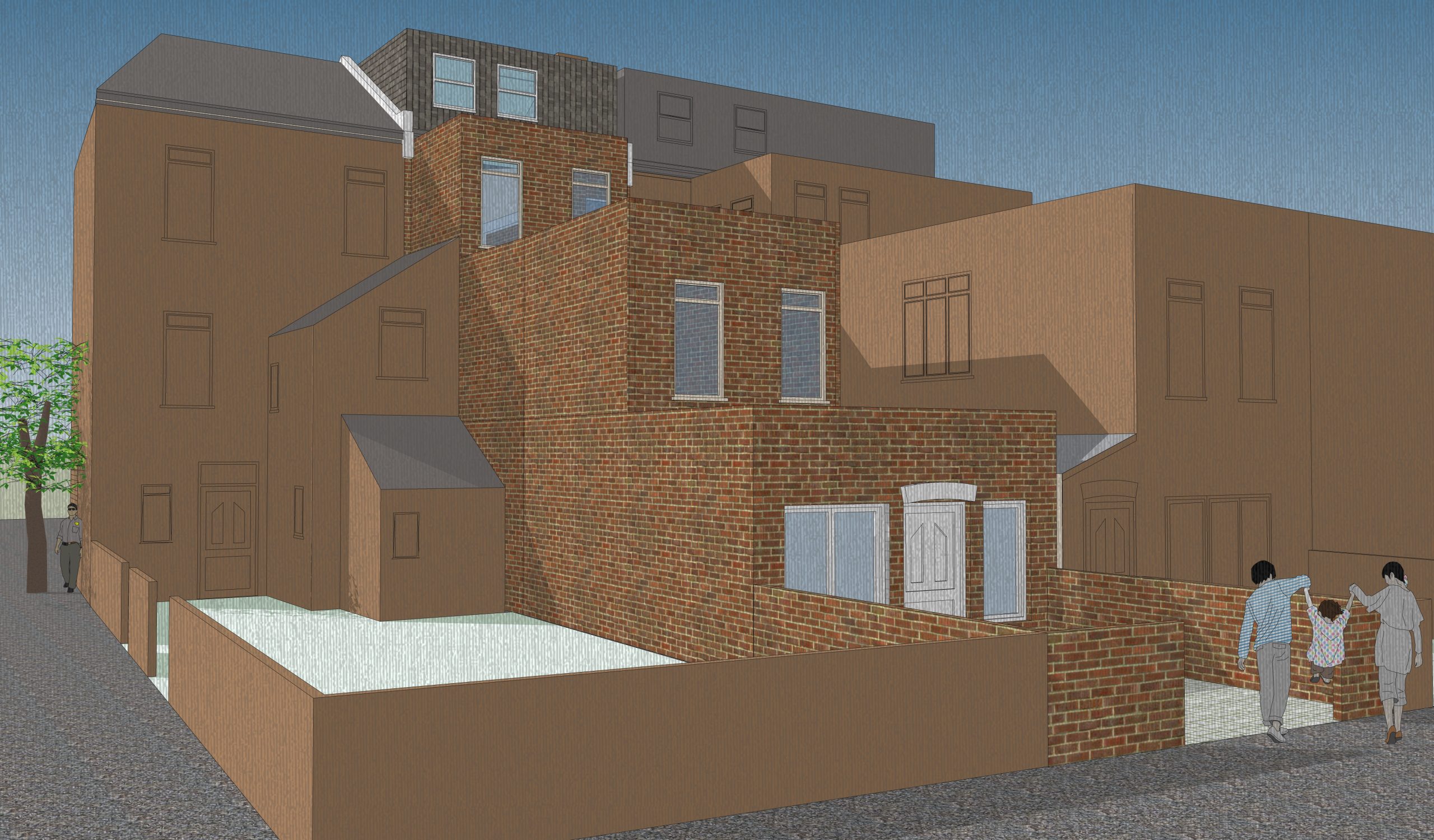

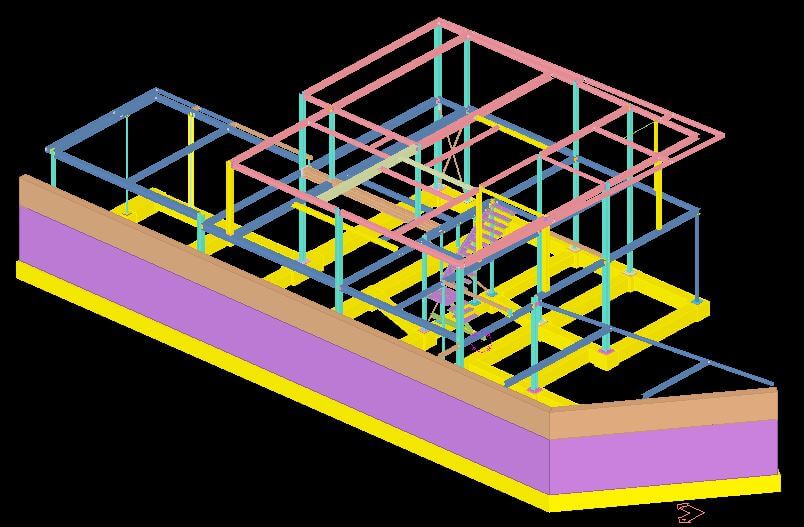

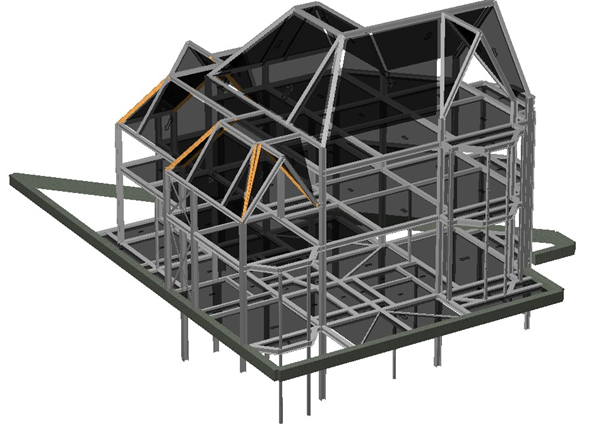

The process relied on existing processes and Beta worked with process equipment suppliers in Italy and Holland to develop the process flow diagram. A list of all equipment needed was drawn up and our plant engineers developed the plant layout. Our consulting process engineers worked with civil/structural and mechanical/electrical engineers to draw up the detailed plant layout. This lead to an equipment list and a plant design that was used in developing a budget and a construction programme.

The plant developer, who is an existing importer of LABSA, used our design, programme and estimated costs to take a loan to start construction. The project has now received final investment decision and we look forward to working with the client in the construction stage.

Client: Confidential

Architect: Beta Design Consultants

Location: Erbil, Iraq

Related projects

Action Court Warehouse Extension

Read More

Value Engineering for Warehouse and Office Building

Read More

Planning Permission for New Warehouse, Ealing

Read More

Three Story Warehouse Steel Structure Design

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

Stage 50 Bovingdon Airfield Studios

Read More

Stage 50 Wycombe Film Studios Village

Read More

United Downs Deep Geothermal Power Plant

Read More

Wycombe Air Park- Data Centre

Read More

Planning Permission for 21 Boston Road Townhouse Conversion

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

CFRP and HPC Concrete Strengthening for Brindleyplace

Read More

Engine Yard Punching Shear Slab Strengthening

Read More

CPS House Jacketing to Strengthen RC Beams

Read More

BP Deep Water Sump Assessment and Concrete Repair Design

Read More

Planning Application for Three Story Residential Building

Read More

BP Heater Foundation Concrete Repair

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

BP GF Gas Plant – Slug Catcher Foundation Walls RC Repair

Read More

Fulham Palace Road Temporary Works Design

Read More

Harwell Campus-Concrete Strengthening

Read More

Helmsley Place-Steel Connections Design and Detailing

Read More

Kennedy Institute Extension - Flat Slab Punching Shear Strengthening

Read More

Planning Permission for a Basement in a Conservation Area

Read MoreLondon Hippodrome Roof Extension – Structural Design and Detailing

Read More

One West Point – Design of Support System for Cladding

Read More

Structural Design of 3 Storey Building

Read More

Queens Rise- Steel Structure Connection Design and Detailing

Read More

St Peter’s Hospital Staff Accommodation, Piled Rafts Design

Read More

Bus Depot Electrification Harrow

Read More

Grove Park Gardens 4 Storey Residential Development

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More

Concept Design of Cité Administrative Koloma

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

RAAC Investigation and Structural Strengthening

Read More

Peckham Arch Condition Survey & Life Extension Consulting Services

Read More

Nant Melyn Bridge Inspection for Assessment

Read More