Fulham Palace Road Temporary Works Design

Beta Scope

- Visual inspection and general structural survey of the property and the collapsed gravity masonry retaining wall

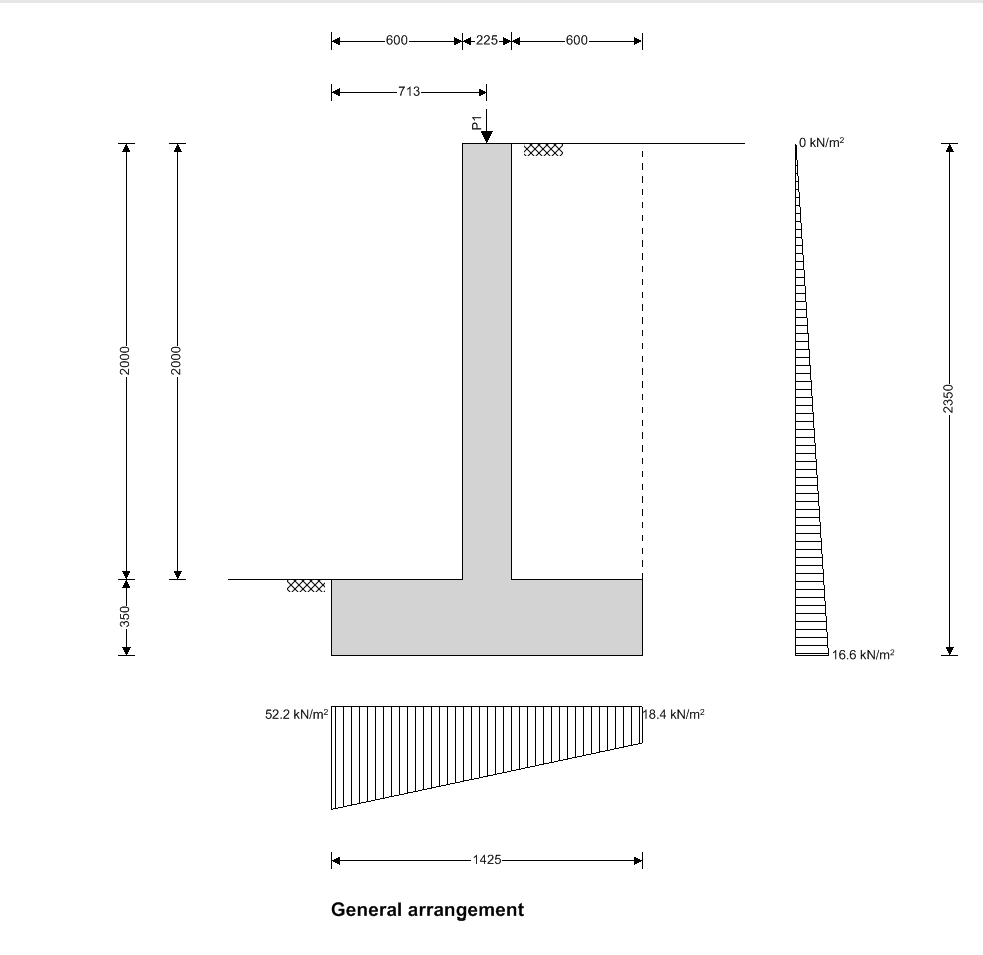

- Evaluation of the hydrostatic and surcharge loading on the retaining wall in the normal wet condition and in the saturated condition

- Advising the insurance companies on the most likely cause of collapse

- Advising the client and the local authority on the repair method

- Preparation of a method statement and temporary works design

- Preparation of specifications for foam concrete and resin injection

- Preparation of construction transport management plan and swept path analysis

- Preparation of services plan to coordinate excavation around HV and LV cables, coordination with all utility suppliers including UKPN, BT, VIRGIN, Thames Water and Cadent Gas.

Background

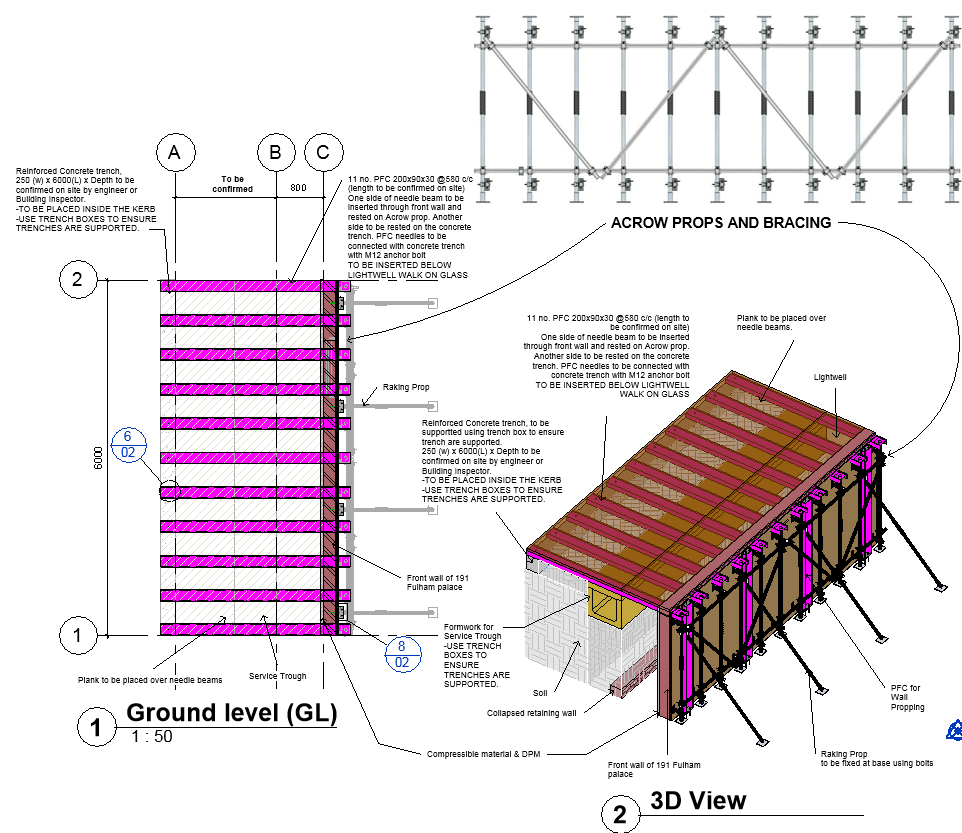

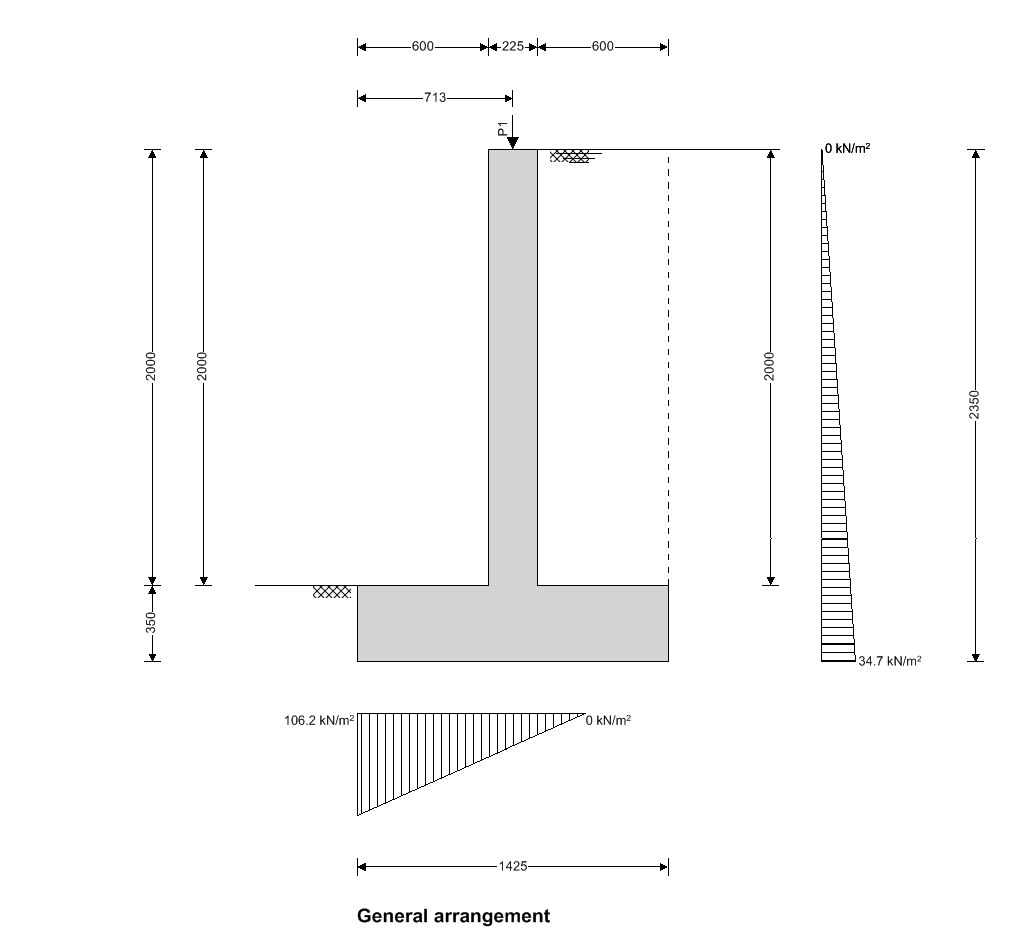

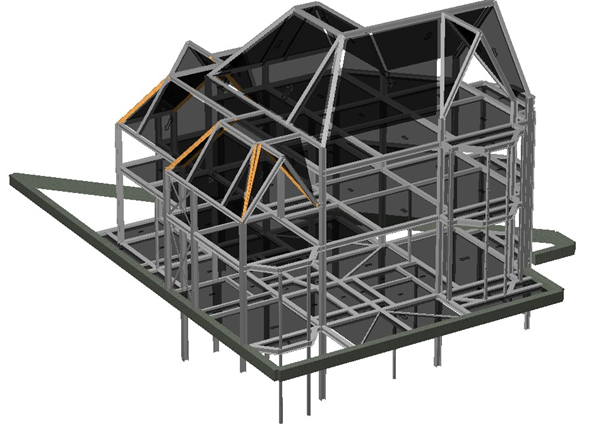

Beta Design Consultants were commissioned by the Client to inspect a collapsed basement wall that retains soil under a busy high street and advise on required repairs and prepare the method statement and the temporary works design for the commercial property. The front property has basement lightwell and masonry retaining wall under the footpath. Footpath collapsed due to the failure of the retaining wall. It was believed that the failure of the retaining wall was due to increased lateral pressure believed to have been caused by the water leakage from the water mains pipe. The affected area lied in the highway vicinity which was a risk to the public. The collapsed section was temporarily barriered off with partial lane closure and the structure deemed dangerous by the council.For the contractor to carry out the repair works Beta Design Consultants were required to come up with a temporary works design and construction method approved by the Council.

Beta Solution

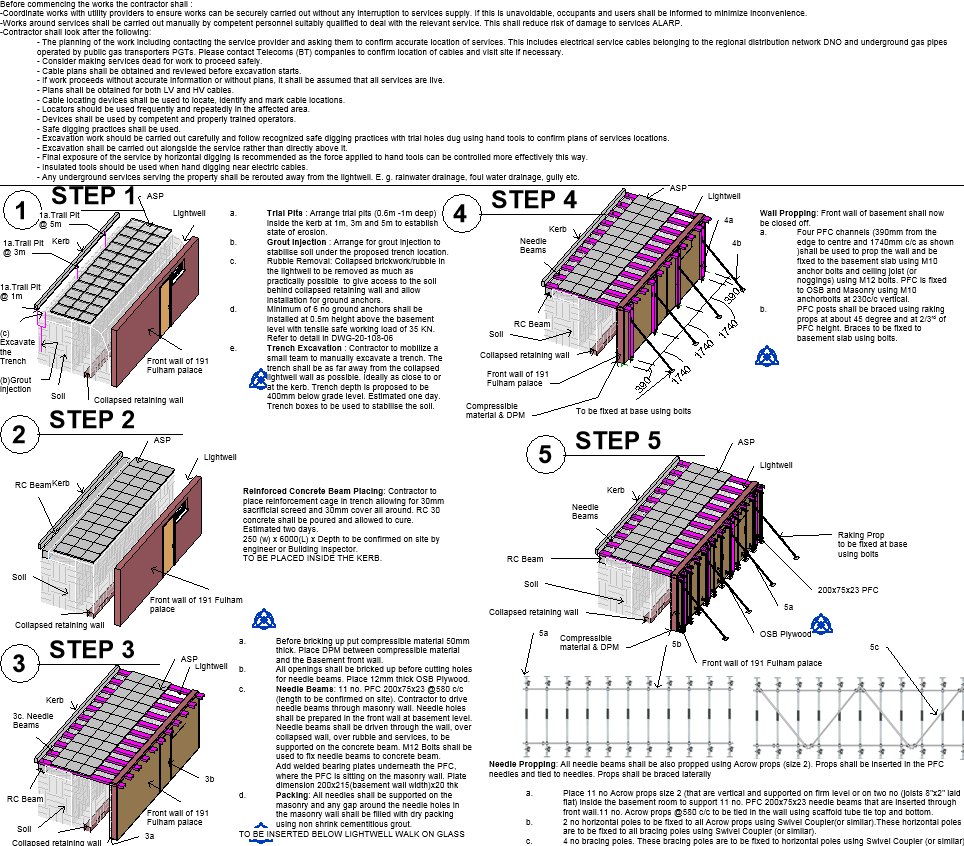

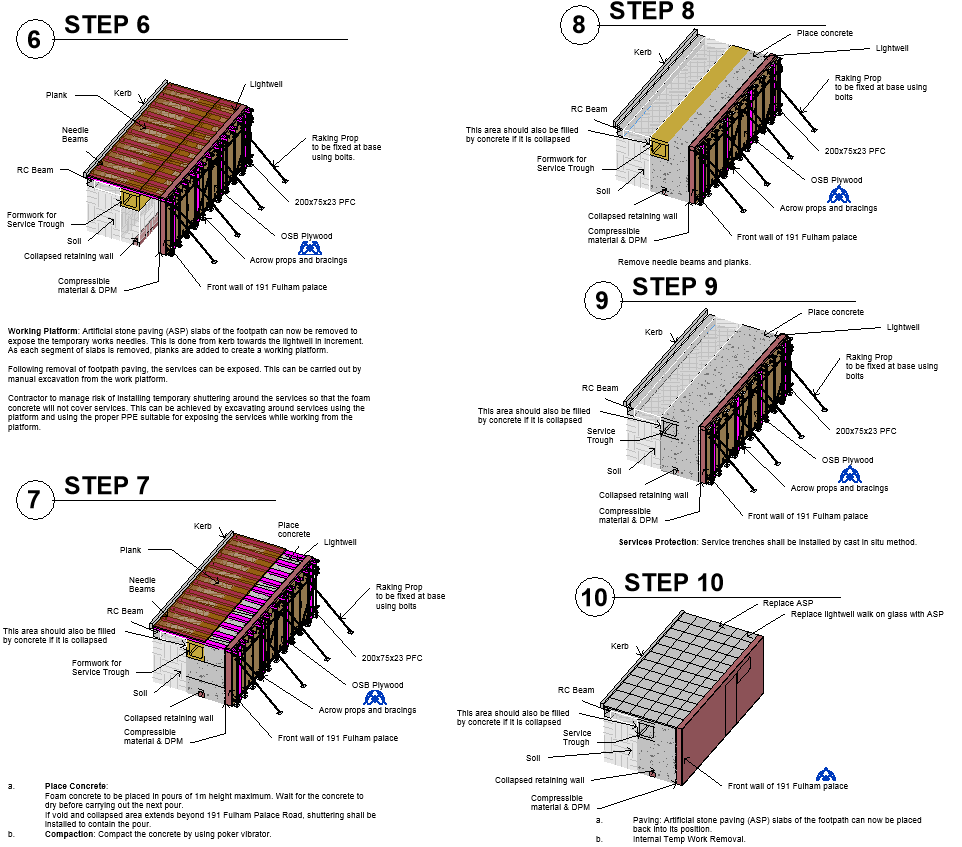

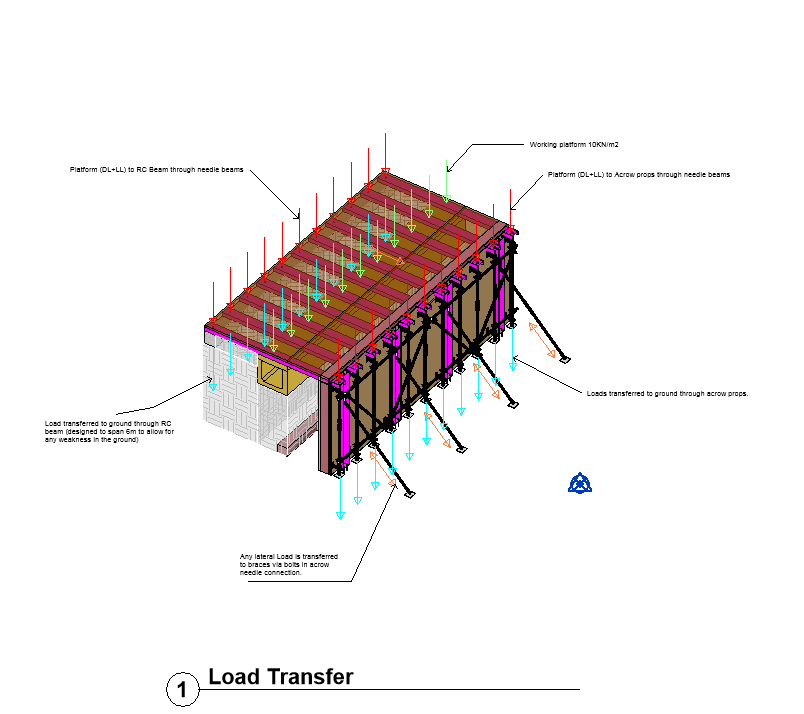

Beta Design Consultants proposed trial pits to establish the extent of soil erosion, to advise on the extent of the grout injection that would be necessary. They proposed working platform supported on the needle beams sitting on the new concrete beam inside kerb and Acrow props on the basement. Cast in-situ trough was designed to protect the services. The new gravity retaining wall created with foam concrete was proposed to be anchored to the soil using ground anchors so that new gravity wall will not transfer the load to the basement wall. DPM to be applied between basement wall and the compressive material so that retaining wall will not transfer any dampness to the basement wall.

Practical Details

Cast in-situ trough was designed for highway loading. Beta Design Consultants produced a detailed construction method statement and risk assessment to ensure works were carried out in a safe, practical and correct sequence.

Related projects

CFRP and HPC Concrete Strengthening for Brindleyplace

Read More

CPS House Jacketing to Strengthen RC Beams

Read More

Value Engineering for Warehouse and Office Building

Read More

Harwell Campus-Concrete Strengthening

Read More

Unit 6-7 Queensmere Shopping Centre – Retail Units Conversion

Read More

Stanmore House Strengthening

Read More

Concept Design of Cité Administrative Koloma

Read More

Engine Yard Punching Shear Slab Strengthening

Read More

Brentford Waterfront Block B and C Temporary Works Design

Read More

Brentford Waterfront Block K Temporary Works Design

Read More

BP Deep Water Sump Assessment and Concrete Repair Design

Read More

Planning Application for Three Story Residential Building

Read More

BP Heater Foundation Concrete Repair

Read More

BP GF Gas Plant Asset Integrity and Refurbishment

Read More

Three Story Warehouse Steel Structure Design

Read More

Kennedy Institute Extension - Flat Slab Punching Shear Strengthening

Read More

Planning Permission for a Basement in a Conservation Area

Read More

Structural Repairs of a Listed Building

Read More

Orchard House – RC Column Strengthening using CFRP

Read More

St Peter’s Hospital Staff Accommodation, Piled Rafts Design

Read More

Bus Depot Electrification Harrow

Read More

Nant Melyn Bridge Inspection for Assessment

Read More

Grove Park Gardens 4 Storey Residential Development

Read More

Coast Drive Visitor Centre, Watersport and Beach Huts

Read More

Structural Assessment of Henley Masonry Arch Bridge

Read More

Peckham Arch Condition Survey & Life Extension Consulting Services

Read More

Pembroke Road Footbridge - Structural Investigation & Strengthening

Read More

RAAC Investigation and Structural Strengthening

Read More

Concept Design of Sedhiou Bridge and Roads Network

Read More

Spire Academy (Horizon Academy) Car Park Refurbishment

Read More

United Downs Deep Geothermal Power Plant

Read More

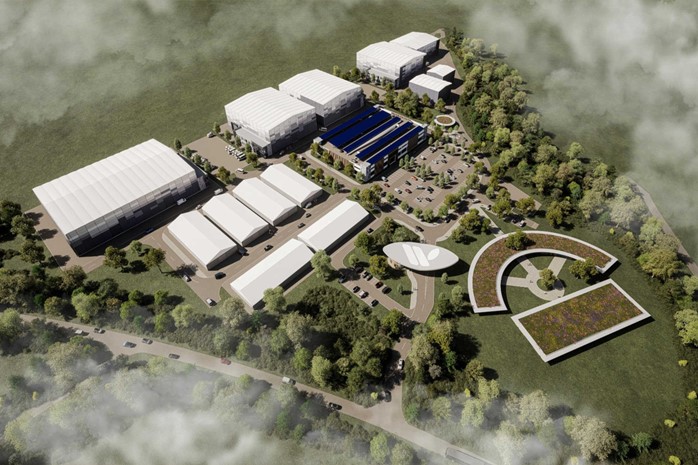

Stage 50 Wycombe Film Studios Village

Read More

BP GF Gas Plant – Slug Catcher Foundation Walls RC Repair

Read More

Helmsley Place-Steel Connections Design and Detailing

Read More

Planning Permission for New Warehouse, Ealing

Read More

Polybags Ltd Warehouse Extension in Lyon Way

Read More

One West Point – Design of Support System for Cladding

Read More

Structural Design of 3 Storey Building

Read More

LABSA Sulphonation Plant Erbil

Read More

Energy from Waste Plant - Process Water Drainage Design

Read More